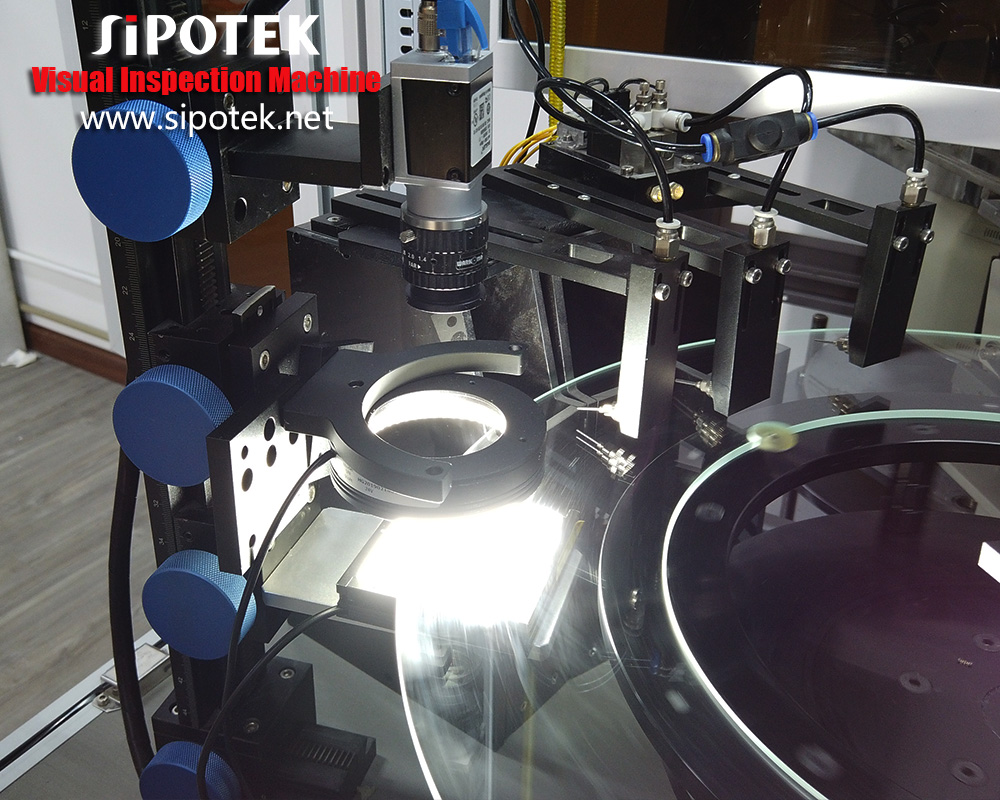

Generally, a vision system contains industrial cameras, industrial lenses, visual light sources, image capturing system, image processing software, sensors, motion and control devices, etc. Before we can understand what will be inspected and which type of vision system is suitable, we need to confirm the expected structure of the project such as environment, quantity of workstations, space for installation, motion, accuracy of the detection, the speed, language of the system, any third-party tools, etc.

There are two type cameras used in industrial application, the line scan camera and the area scan camera. Our vision system uses the later so we are going to introduce the area scan camera.

– The image integrated surface

When the light is passing through the lens, there is a plain surface. It’s a circle.

– CCD chip

There are generally 4 specifications indicated the size as 1/2″, 2/3″, 1/3″. If the lens is smaller than the chip size, the shape of the capturing graphic will look like a round circle.

– Focus length

The distance from the lens to the imaging surface

– Perspective angle

The width that the lens can observe

– Working distance

Generally we should pay attention to the minimum working distance. There is no limited for the maximum working distance.

– Field of vision

The effective working area that was covered by the lens

– Depth of field

While the field of view is horizon, the depth of field is vertical

- The smaller the focus length, the larger the viewing angle and field of view, and the shorter the working distance.

- Commonly used lens are 50 mm, 25 mm, 16 mm. 50 mm field of view is the smallest, the minimum working distance is the longest

- In practical applications, the visual inspection system has limited space, so you need to pay attention to the minimum working distance.

- Distortion: 50 mm lens distortion is the smallest, if you want to accurately measure the distance, you can choose a 50 mm lens as first option.If you need to check the characters, you can use a lens with smaller focal length.

- Light: The farther working distance, the less lighting you will have, and the more noise you will

Features of are scan cameras

– The area scan cameras can read more information, including measurement of area, shape, size, position, some times even temperature.

– For products that can keep still status or lower speed inspection, area scan camera will be the better option.

For more information, vision our home page on www.sipotek.net

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/