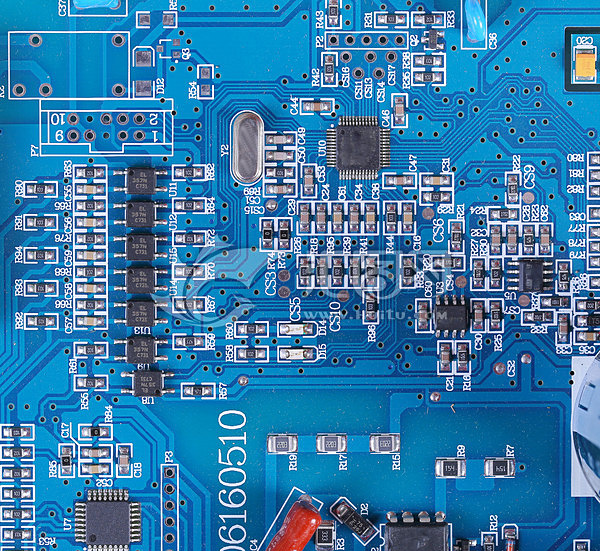

PCB board is also called printed circuit board which acts as link in electronic components. PCB board is a core component in electric products and is a important parts. Therefore, quality control is especially important, a slight error can make the entire electric product stop working.

Because electric product body has high requirement for the precision. In the product production process, each process is quite important, if one of the process is wrong, the whole product may be rework or scrapped directly. In the traditional production process, PCB board inspection mainly replies on direct observation by human eye. Such detect methods have many disadvantage, so it is necessary to adopt machine vision inspection method to replace human eye inspection.

Machine vision inspection technology is based on the image processing algorithm to realized by digital image processing and pattern recognition. Compare with the traditional manual detection technology, it has improved defects detection efficiency and accuracy.

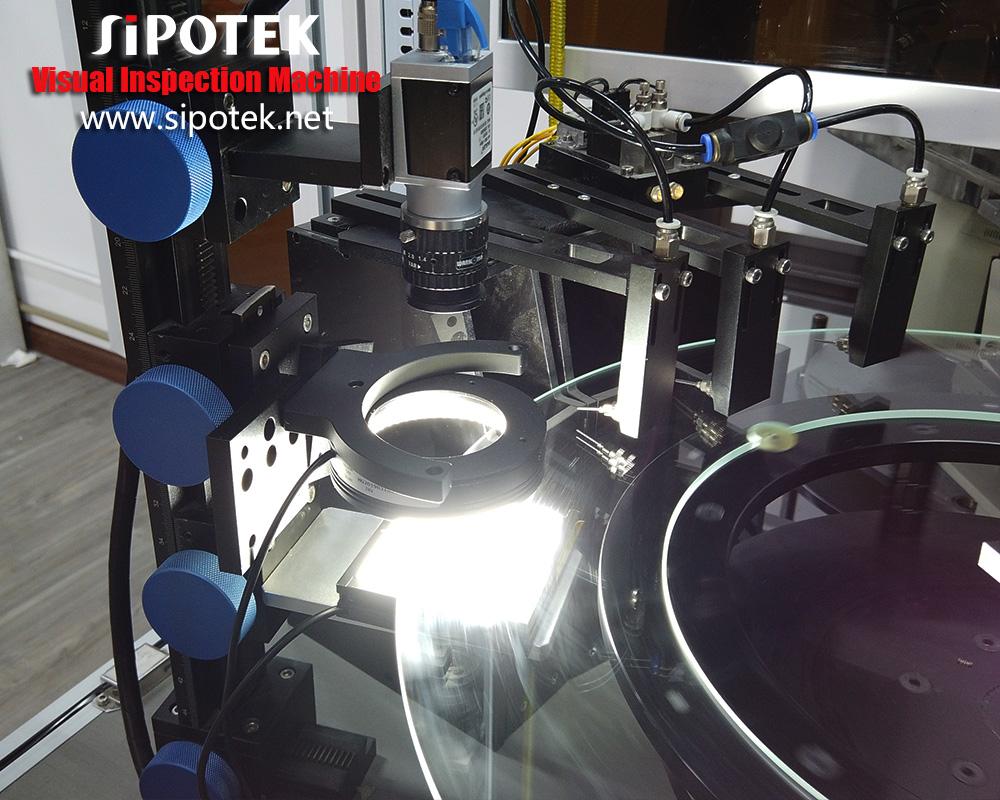

In the article, Sipotek will explain the optical visual inspection application of PCB board electric components.

Inspection requirement: it is necessary to inspect the missing and correct errors of each character on the PCB board, the presence or absence of the capacitor and the extreme polarity of the resistor.

Inspection principle: in this case of article, using Sipotek machine vision software for detecting, this software can be written and inspect according to customers requirement and stared secondary development. Through the qualified products to establish the standard template of each section and set the corresponding parameters. Each detection frame can be inspected at the same time. Comparing with the inspection results to the template similarity to assess whether the product meet the specification.

Machine vision inspection features:

- PCB machine vision inspection machine can automatically identify defective product and sort them out. HD camera can distinguish and identify 0.001mm small differences, automatically inspect broken disconnection,wide line or narrow line, short-circuit, foreign matter and other defective problems.

- The labor intensity of employees is greatly reduced, the loss is eliminated; the inspection personnel are saved, the product anti-work hours are reduced; the scientific image of the factory in the customer is improved, and the product quality is fully confident.

Shenzhen Sipotek technology Co.,Ltd. has many years of experience in the machine vision industry, and has accumulated rich experience in the field of machine vision applications. There are many successful cases and visual inspection solutions. Spotek Technology has always been committed to machine vision products. Production, development, application and sales, providing customers with total machine vision solutions and services, applying machine vision technology to intelligent production.

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/