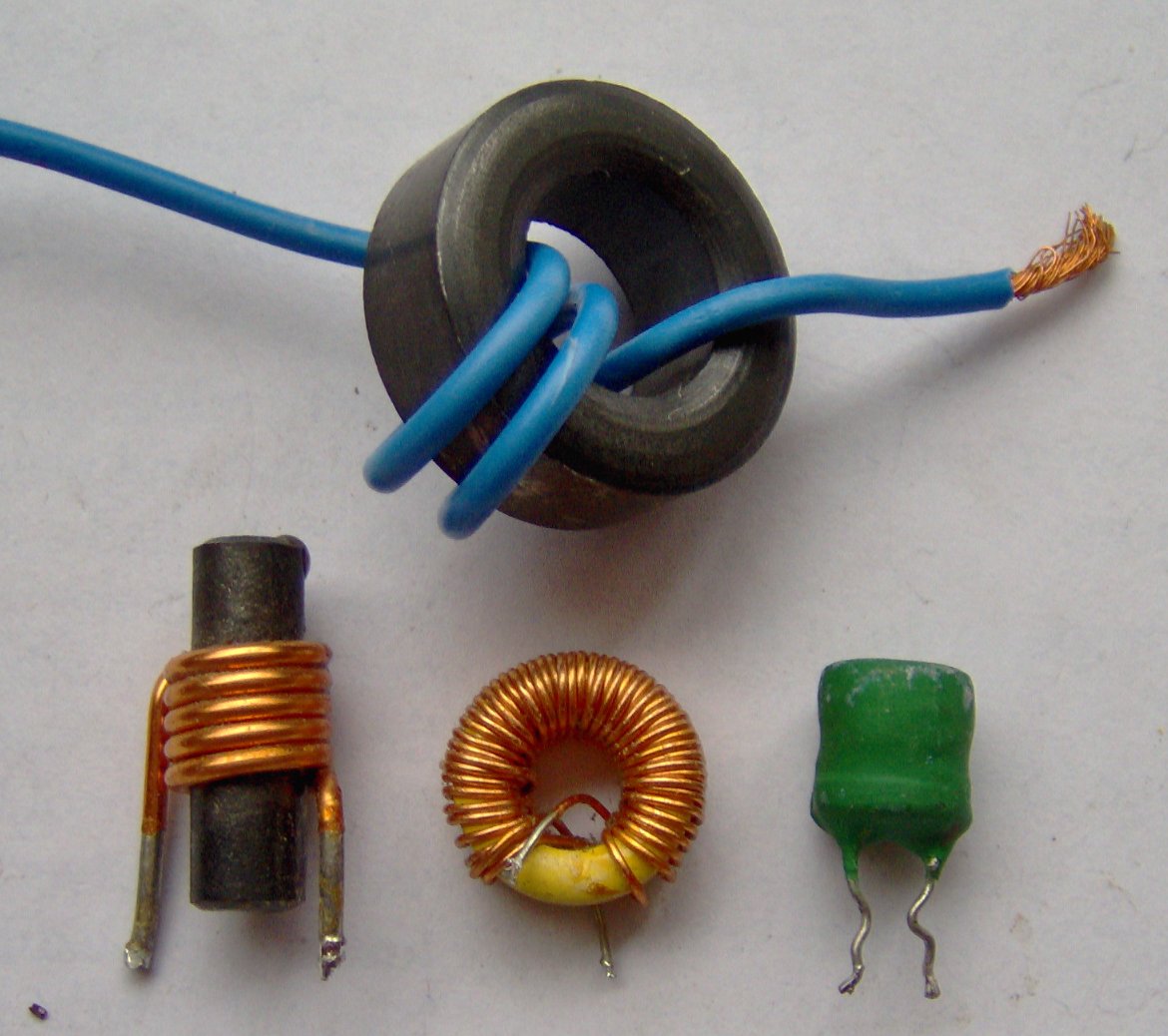

Sipotek machine vision inspection systems can be used in any number of industries in which quality control is vital. Take eletromegnetic inductance coil for instance. Wire was winding with a ferrite rod. Glue was covered on the surfce to keep the choke stable and fixe. All small processes need to be confirmed by inspection facitlity because there are some quality problems happened usually. For example, foreign material by less epoxy on surface; woring core location during assembly; soldering length incorrect; lead bend problems and gap betweetn wires.

HPIM1067.JPG

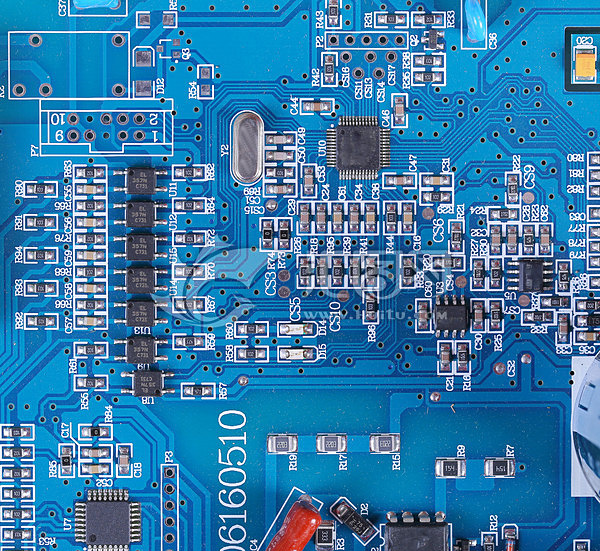

Vision inspection systems (sometimes referred to as machine vision systems) provide image-based inspection automated for your convenience for a variety of industrial and manufacturing applications. Though not a new technology, 2D and 3D machine vision systems are now commonly used for automated inspection, robot guidance, quality control and sorting, and much more.

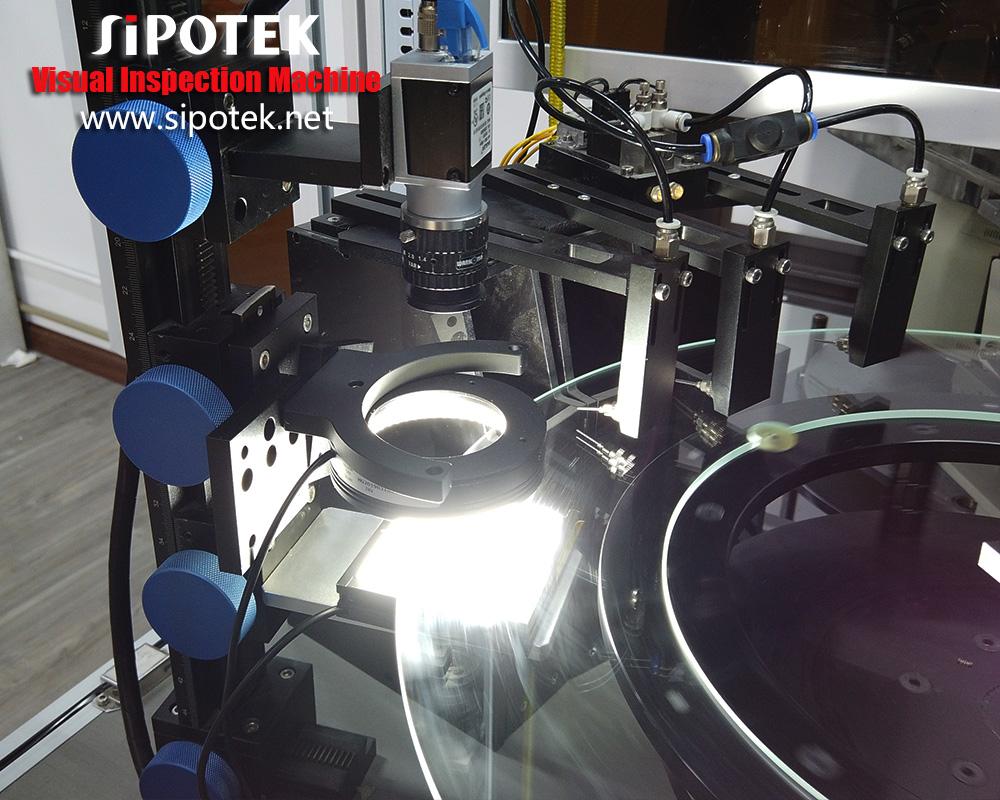

For eletromegnetic inductance coil chokes vision inspection projects, sipotek provide a solution by using T300 high speed automatic rotary visioni nspection machine.

The complete system included feeding, inspecting and output loading. We use vibration feeders to hold a massive quatity of chocks. One operator is required to do the manupulation for a whole daily work. Everytime, the operator pulls the big quantity of unexpected chokes into the vibration bin.

Now the chokes are vibrating and ready to go for the inspection station where 2 camera modules are set with industrial lenses and lighting sources. The inspection station is made by a profession glass plate where the coil chokes are lying onside and being still. In our solution , front lighting and backlighting methods are used.

After the inspection system gives analysis from the images taken by the cameras, the chokes coils are sorted either as OK for pass, orNG for rejection. Now the sensors will give signals to the air valve blowing mechanism where bad quality chokes are rejected to NG bin and good quality chokes are blew to Pass bin.

The operator now can collect all the Pass chokes to the next station. The accuraty by vision inspection system will be 99.99%. You don’t neet to do a second time checking before selling to customers.

By using Sipotek intelligent inspection systems come equipped with a camera or multiple cameras, and even video and lighting. Vision systems are capable of measuring parts, verifying parts are in the correct position, and recognizing the shape of parts. Also, vision systems can measure and sort parts at high speeds.

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

Sipotek Visual Inspection Machine

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-18666216027

Email: [email protected]

Website: http://www.sipotek.net