The advantages of machine vision inspection system are mainly reflected in non-contact detection and measurement, long-term stable work, etc. Using machine vision solutions can save a lot of labor resources and bring considerable benefits to the company, so its application is more and more extensive.

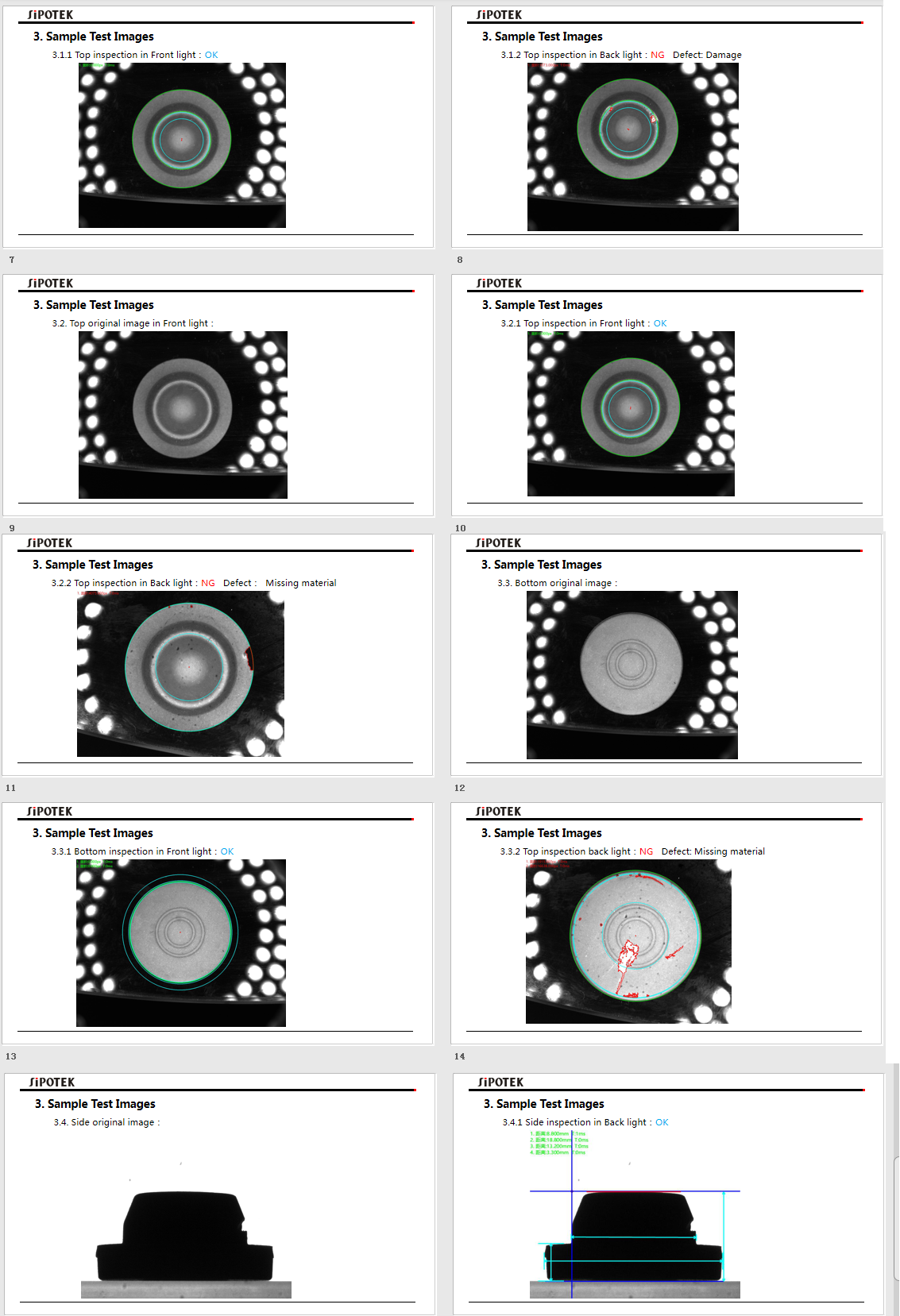

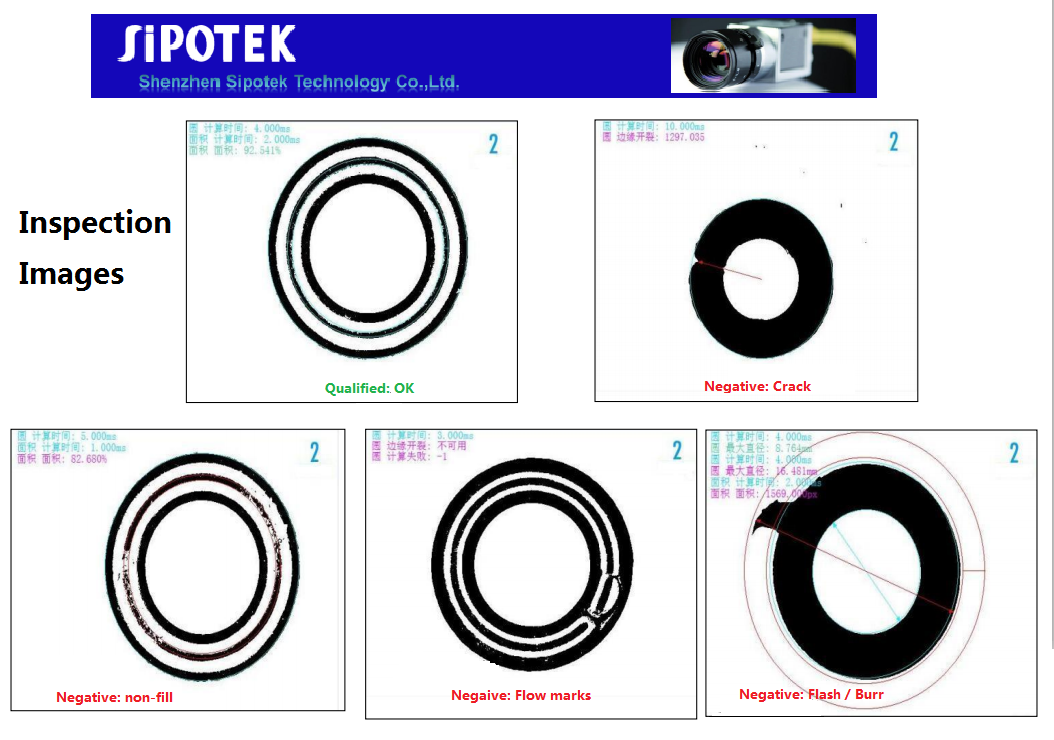

The machine vision system has a measurement function that automatically measures the size of the product, such as profile, aperture, height, area, etc. Dimensional measurement is an indispensable step in both the production process and the quality inspection after the production is completed, and machine vision has its unique technical advantages in automated optical inspection dimensional measurement.

For example, this non-contact measurement method can avoid damage to the object to be tested and is suitable for situations in which the object to be tested is not accessible, such as high temperature, high pressure, fluid, environmental hazard, etc. At the same time, the automated visual inspection machine vision system can simultaneously work on multiple sizes. The measurement realizes the rapid completion of the measurement work and is suitable for machine vision online measurement. For the measurement of the small size, it is the advantage of the machine vision system. It can enlarge the object to be measured with a high power lens, so that the measurement accuracy is above the micrometer.

The optical measuring equipment is based on the relative measurement method, which is derived from traceability, magnification calibration, automatic edge lifting and screen image measurement. In precision measurement, the magnification requirement is 35* or more to obtain micron-level precision. At this time, the visual line width is less than 5mm. For the measurement of objects above 5mm, it is necessary to shift the analytical reading and the window measurement synthesis.

For the precise measurement of small size, the use of high-power industrial lens or microscope head, from tiny biological cell diameter, quantity, to small assembly gap size, to smaller mechanical parts, electronic product size measurement, etc. It is the use of machine vision systems.

Although there are many ways to achieve dimensional measurements, most of the measurements are not repeatable, efficient, and robust. The facts show that the dimensional measurement based on machine vision technology has good continuity and high precision, which greatly improves the real-time and accuracy of industrial online measurement, and the production efficiency and product quality control are also significantly improved.

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/