Inspection is the process of examination, measurement, testing , gauging, and comparison of materials or items. An inspection machine determines if the material or product is in proper quality and condition, and if it conforms to the applicable or specified requirements. Inspection is generally divided into 3 categories:

- Receiving inspection

- In-process inspection

- Final inspection

In quality control which is guided by the principle that quality cannot be inspected into a product, the role of inspection is to verify and validate the variance data.

Visual inspection ,in some way, was brought in to the quality process. Its process was like human naked eye inspection, visual inspection, instead of human eyes, read the signals from images captured by industrial cameras. The signals will be transmitted and be visual analyzed. It’s the observation of obvious, external features to arrive at a general estimate.

In manufacturing, a measure of excellence or a state of being free from defects, deficiencies and significant variations. It is brought about by strict and consistent commitment to certain standards that achieve uniformity of a product in order to satisfy specific customer or user requirements. Quality was defined as the totality of features and characteristics of a product or service that bears its ability to satisfy stated or implied needs. Defects in a product will cause harm for customer reliability and therefore production will decrease because trust will be lost.

Today we will learn some printing quality inspection information. According to Guy Yogev, director of marketing for Advance Vision Technology (AVT), the inspection system should also address common defects like

Color variations

Misregistration

Misprints

Spots

Characters

Reistration

Streaks and scratches,

Splashes

Scumming and flawed edges

Therefor choosing the right inspection system can yield a marked increase in product quality, process control and through these improvements create new business opportunities. Packaging suppliers with an inspection system are commonly at an advantage when brand owners are looking for a vendor.

Though inspection has become important to a wide variety of vertical markets including medical devices, chemical products, food and luxury good packaging markets. It’s not surprising that pharmaceutical companies are typically among the first to incorporate sophisticated, multifaceted inspection and quality control systems into their production environment. It’s a vital part of supply chain safety, said by Yogev.

Today’s inspection system are providing a lot morn than just print inspection and thus providing additional tools to help the operator and the management of the print house to control the printing machines, maintain consistent colors ,gather production information and product valuable statistics. Amir Dekel, VP, business unit manager print, says that the vast majority of package printers embrace the technology quickly, but in some cases, the operator might not take to the technology right away. That concern is quickly dissolved once the operator sees how fast the system finds a defect. While all facets of defects can be detected by inspection systems, the most instrumental benefit of the system is in catching defects that will be obvious on the end products, but difficult o catch on press.

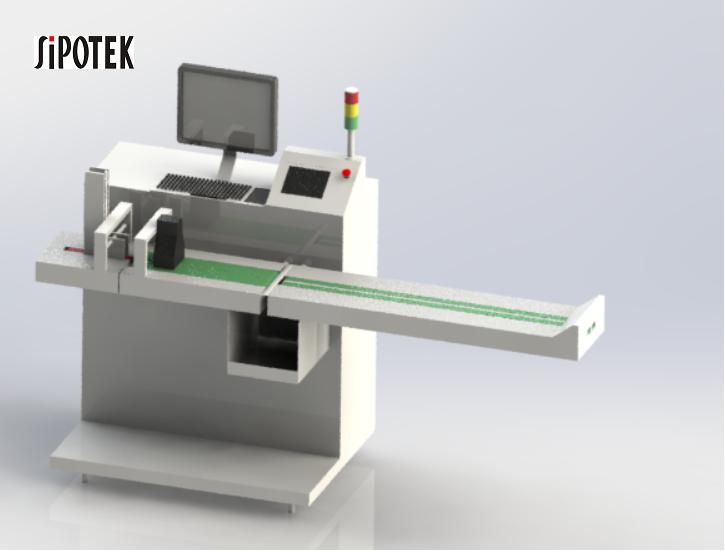

Shenzhen sipotek technology co., ltd has designed an automatic tag counting inspection machine, controlled by fast and stable PLC, precisely transmitted by servo motor, convenient to count the quantity for packing. The unqualified system contains a rejected mechanism, inspected by vision software system. The automatic feeding is set on the start line, printed tags will be fed one by one in a fast speed on a conveyor belt. The efficiency will be 200-300 sheets per minute, covered the size range from 200mm*70mm to 40mm*20mm, with the thickness of 0.5-1.5mm.

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/