Machine vision, abbreviated as MV, is anything that helps the computers see and explore the world. From camera lenses and mass manufacturing units that monitor labeling and processing of factory items to virtual reality and augmented reality, everything is a courtesy of technology being able to look the world around us. Specifically, machine vision is a term used to denote software and programming implementations that help in image processing. It is these image processing properties of machines that have also earned their sight the label of computer vision. The facial recognition technology is also another use of machine vision.

Basically, the machine vision system is composed by hardware and software system.

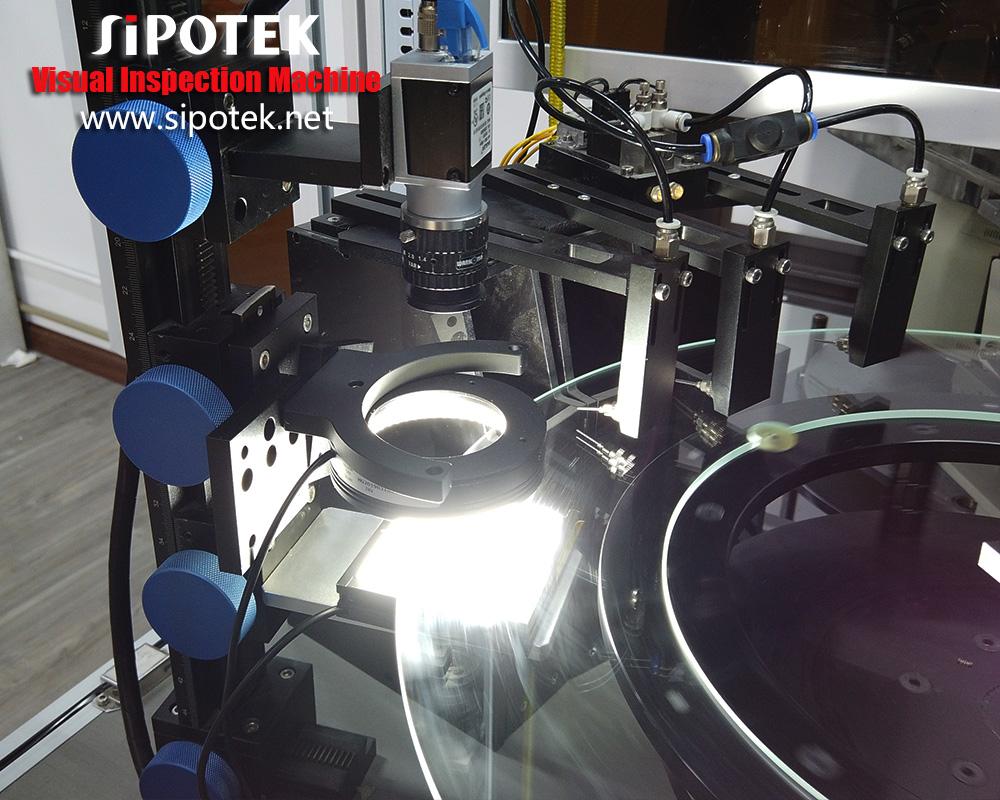

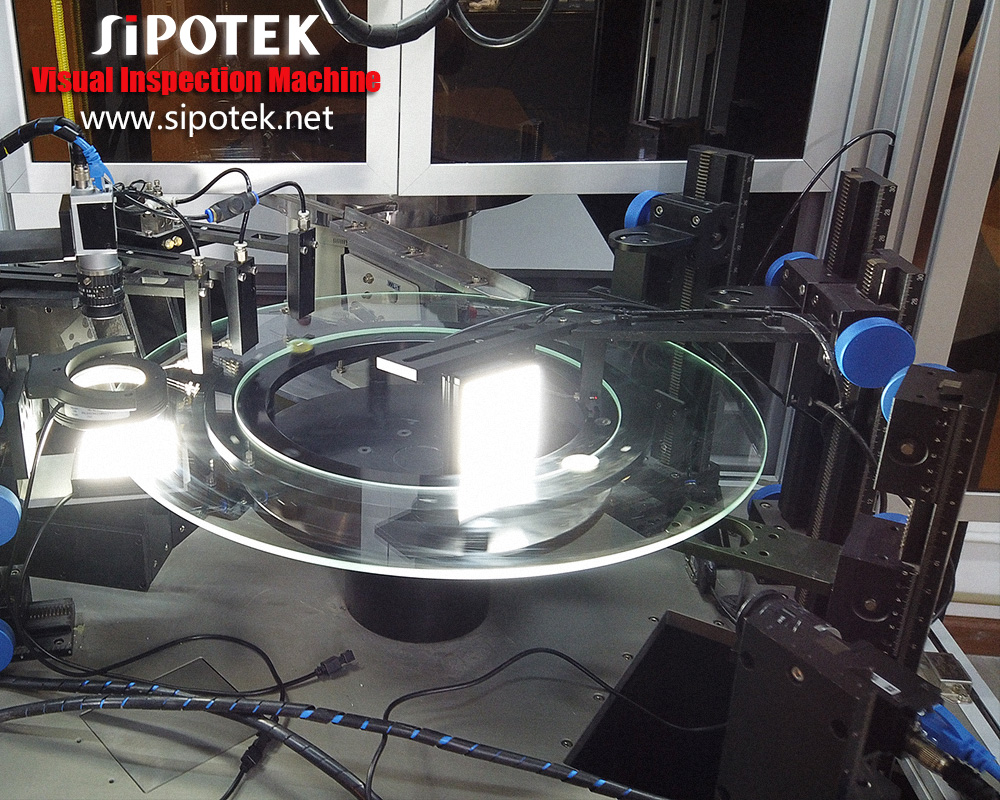

The Image Capturing System- Hardware

Digital cameras and smart phones, for example, are the most basic development of MV function in which you basically just shoot a photo, capture an image of the object. So it not only relates to manipulates of images and videos but their recording as well. This is the part which enables the machines to see.

The Image Processing System-Software

Image processing is the most dynamic and essential function of machine vision technology. There’s so much detail in it that image processing is a separate academic subject with a distinct history and active research around the world. This is the part that enables the machines to not only see but also understand the details of the picture.

The Image Manipulation System-Software

Your mind may inadvertently drift to Photoshop and rightfully. While Adobe Photoshop and similar software are a stunning example of machine vision achievements, they also offer tools to manipulate the images to almost do magical things. For example, I extensively use its crop and optimization functions so the photos on the pages load faster.

It’s generally acknowledged that a wide range of industries can apply this technology of Machine Vision. It contains automotive, semi-conductor, electronics, medical device & pharmaceutical, printing and packaging, general mechanical engineering, food processing, solar production, process engineering, final inspection of sub-assemblies, engine part inspection, label inspection on product, checking orientation of components, traceability of manufactured products, Packaging inspection, checking laser marks and cuts, food pack checks, reading bar codes, etc.

The manufacturing industry has the most reasonable and the most repeated use of machine vision technology. Labeling of bottles, cans and any item that has a painted or ingrained label uses machine vision solutions to help the software decide where to sketch the labels. Computer vision is also used for product inspection and consistency as well. Items can be broken or incomplete. Laser vision or cameras are used to scan manufactured items and that the packaging has been properly conducted. By inspecting with fast speed, the machine can do the work doing the labeling, inspection, and keeping thousands of items in the assembly line without neglecting errors.

For more about machine vision inspection system manufacturer,you can pay a visit to sipotek website at http://www.sipotek.net

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]