Vision inspection technology is worldwide spreading across countries, thousand of machine vision enterprises are devoted to research and develop the newest technology to cater every customer. A 500 global leading company produce daily consuming products. Soap is one of their product. If there is an empty box, which should have filled with soap on the producing line, runs into the market, it will easily cause customer complaints.

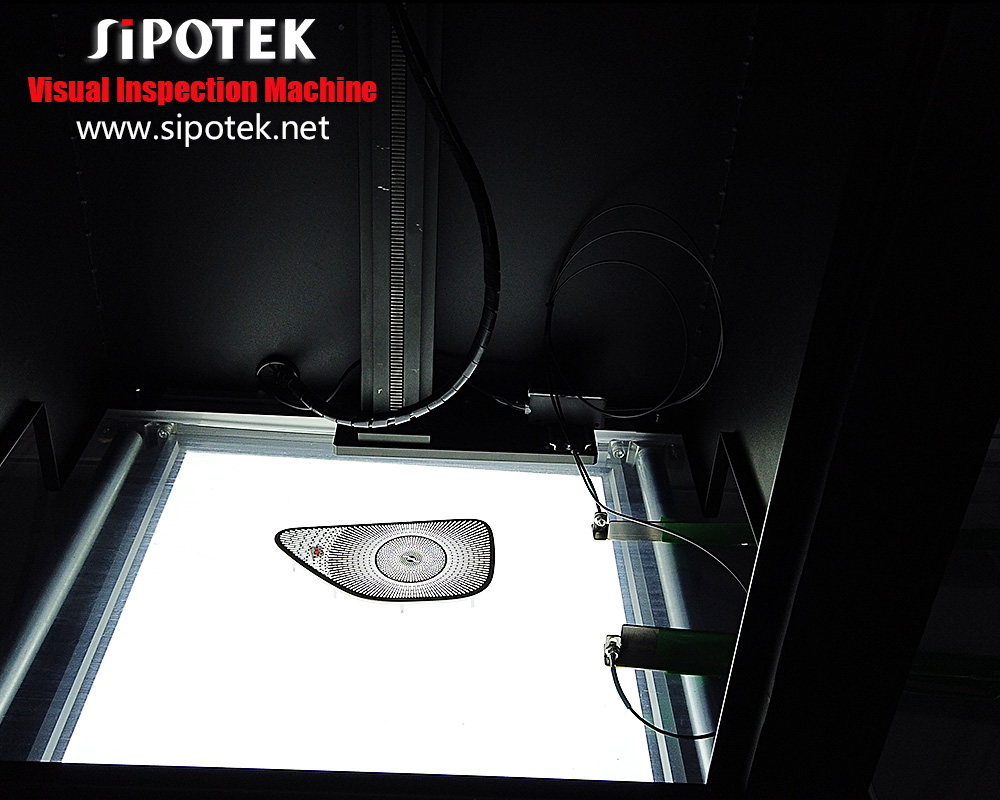

Sipotek Visual Inspection Machine 21

Therefore the company establish a protection and correction team to solve the issue and they finally come with a solution, to add a “weight scale” at end the end of the production line. If there is a product with unusual weight, the optical machine will sort out and make rejection. This solution earns many agreement and was wide used thereafter.

The same situation happens in one of our national soap manufacturer, as they don’t have enough resource and money, the boss asked the production manager to solve this issue immediately. The manager felt hard and suddenly he came up with an idea. He found that workers use a high-power fan to blow the wind and drive away the heat. So he took a fan too and adjust the distance and wind speed until it can blow away the empty packages.

Many people will agree that the production manager is smarter than people in the 500 global leading company. However, thinking about future applications, which one will be widely used and which one will be out.

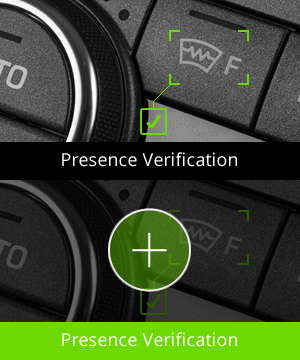

Hereby We will share the method to inspect missing packaging or wrong packing through sensors. Also, we call this presence and absence inspection. All machine vision inspection devices have sensors, whose function is similar to human eyes communicating the nerves to the brain for judgement.

Take mobile phone assembly for example, if the assembly contains multiple accessories, it might occur missing or wrong assemble problems. The optical segregation machine can inspect these problems using machine vision inspecting, and then sort out the unqualified items from production line.

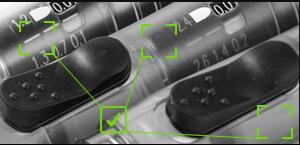

Some missing or wrong packing problem is inspected by optical scanning. They are constantly used in products with multiple parts, such as instrument dials. The working instructions is make comparison of qualified images to inspected images captured by cameras. The inspection system will then distinguish the unqualified images and deliver signals to the system to take actions to eject out respectively.

Sipotek specialized in absence and presence inspection, wrong packing or missing packing by vision inspection technology for over 16 years. With a mutual technique in machine vision, the inspection solution has been applied in automotive industry, precision hardware industry, plastic industry and etc. In the influence of Made in China 2015, more and more manufacturers become interested and put vision inspection facility into use, they are searching a new way to turn the traditional method to industrial automatic inspection era.

About Sipotek

Shenzhen Sipotek technology company limited was established in 2002 and its main businses is machine vision automation system and complete equipment. The company has formed a team with 12 senior personnel on machine vision system and industrial automation engineers. Our targets customers are from industrial of precision hardware parts, electronic components, rubber silicone parts and etc. We provide both online vision system for vision engineers and complete machine for offline inspection for manufactuers.

Sipotek is committed to becoming a leader in visual inspection field, creating values for customers. We provide visual inspection solution with free charger. If you have quality issue, you can consoult us by the following:

For more information,

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-18666216027

Email: [email protected]

Website: http://www.sipotek.net/machines/