Recently we received a magnetic core inductance inspection inquiry from Russian customer:

Dear Sir/Mam,

Good day!

Is inspection of our inductance products possible?

Best regards,

Dmitry

What defects will be happened during the inductance production process?

It is inevitable that magnetic core will have defects in the production process, such as crack, scratch, chip, crystals, dirt and so on. The quality control that relies on manpower detection alone can not keep up with the production speed quickly and efficiently, still less can it be accurate to eliminate subtle defects that are hard to detect with naked eye.

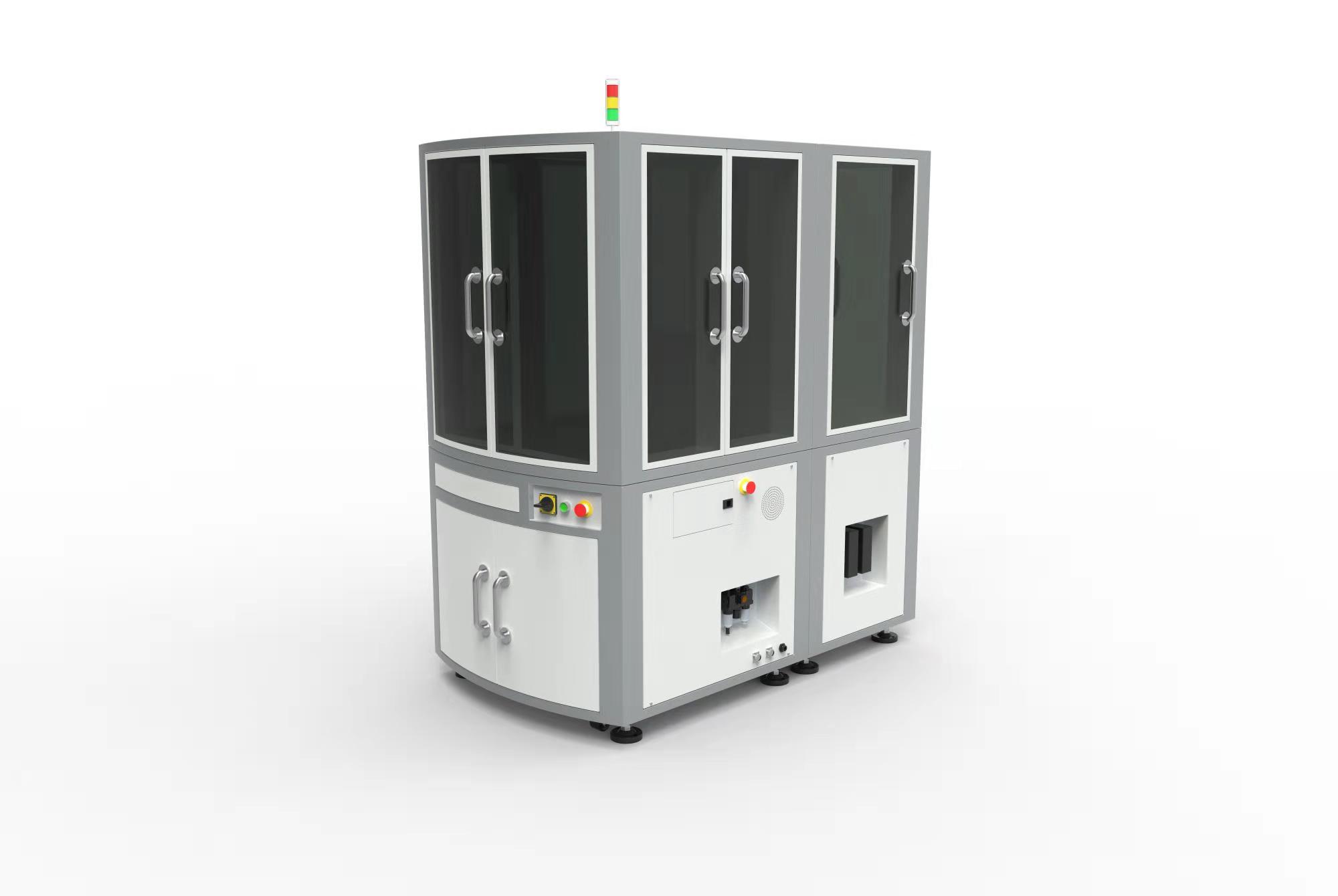

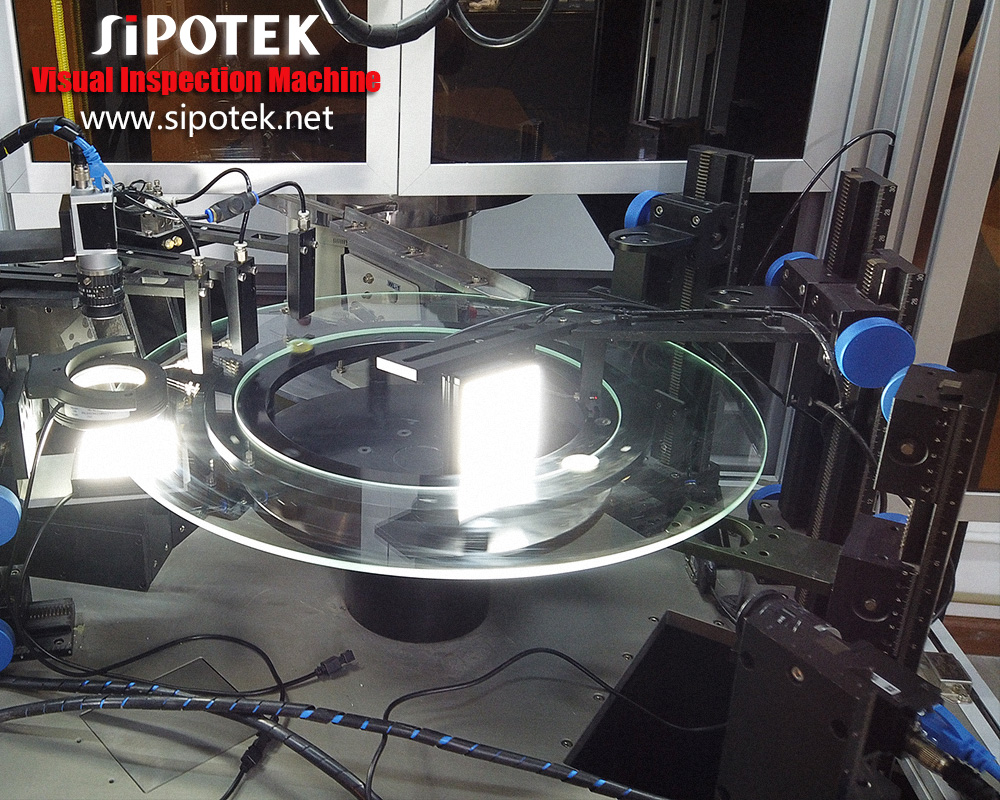

SIPOTEK ultrasonic surface crack detection use thermal sensing inspection camera to replace manpower detection, accurate and fast, save money and time, which can eliminate errors and omissions caused by fatigue in eye detection. Parameters can be set and the detection specifications are unified.

Quickly and accurately identify all kinds of minor defects on magnetic core surface such as breakage, crack, stain, flower surface, scratch, etc. At the same time, it can achieve the function of six-face identification and classcification, as well as detection of silver deficiency, weak scracth and weak spot.

The adaption of SONY ultra-high resolution camera, combined with the hign precision algorithm developed automatically, can realize the recognition speed of 100-1200 pcs/mintue, accuracy up to 0.01mm.

The number of vision inspection of magnetic core inductance appearance defects is 8.42 times that of manual visual inspection, machine vision can replace 6~8 workers.

Application Industry:

Core of Wire-wound Inductor

Wire-wound Inductor

Core of NR Inductor

NR Inductor

Visit http://www.sipotek.net/ for more information about surface crack detection machine application.

Since its establishment 16 years ago, Shenzhen Sipotek Technology Co., Ltd has been committed to the research, development and manufacturing of image technology and machine vision, with more than 70 senior R&D personnel of machine vision system and industrial automation engineers. The company’s key technical personnel are mainly from HUAWEI, BYD, FOXCONN and other first-class manufacturing enterprises, with many years of mature experience in software design, visual and image comparison technology, industrial automation and other aspects.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: +86-186-6621-6027

What’s app:+86-186-6621-6027

Wechat: +86-186-6621-6027

Email: [email protected]

Website: http://www.sipotek.net/