The detect efficiency of CD inductive automatic inspection machine is 400-600 pieces/minute which accuracy rate up to 99% to replace manual inspection, increase production efficiency and reduce production cost. Main detection contents are damage, cracks, dirt and other defections.

Ⅰ: Detection contents and requirement:

Detection workpiece area

Appearance detection of the sample with a length of 8mm, a width of 8.4mm and a high of 4mm

Detection content:

- Bottom positive light inspection

- Top positive light inspection

- Side positive light inspection

- Revise side positive light inspection

- Side positive light inspection

- Revise side front light inspection

Note: all the above detection items can be detected under the image which need to be clearly visible.

Detection efficiency: 150-200 pieces per minute.(according to the sample feeding speed)

Division of work: subdivide the detection steps according to the detect content.

Ⅱ: Equipment composition and main institutions

Overall composition: size:900*800*1850 mm

- Sipotek visual inspection software

- Industry computer

- Display 19 inches

- Industry camera: 6 sets, 1 bottom positive light, 1 top positive light, 4 side positive light

- Industry Lens: 6 sets, 6 pieces FA industry lens

- Professional glass plate

- Magnetic valve

- Reducer

- Vibration cabinet

- Feeding machine(vibration tray, direct vibration, controller)

- Sorting machine(conveyor belt, controller)

Ⅲ. 1. 3D perspective view of the detection machine

Ⅳ: 1 Bottom positive light detection method

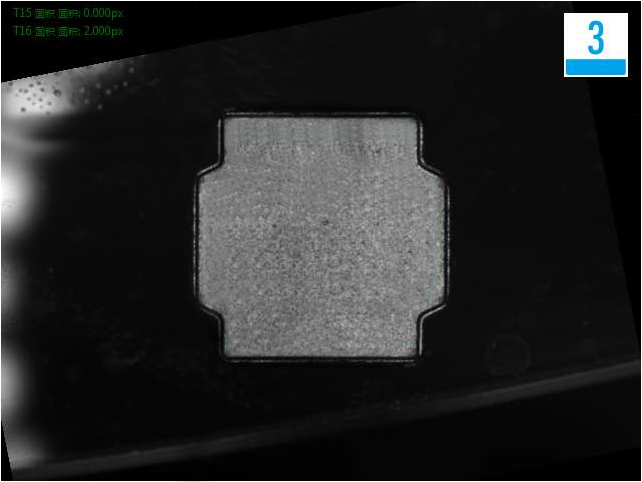

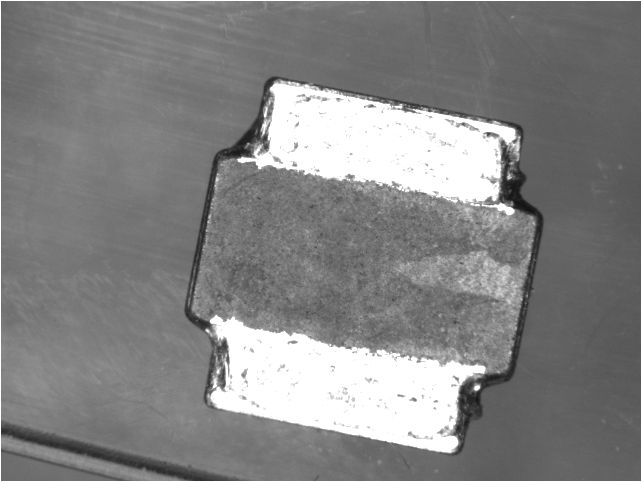

Bottom detection effect original picture:

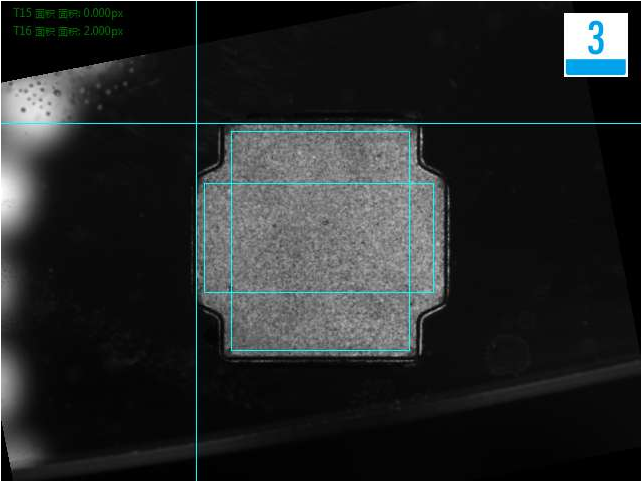

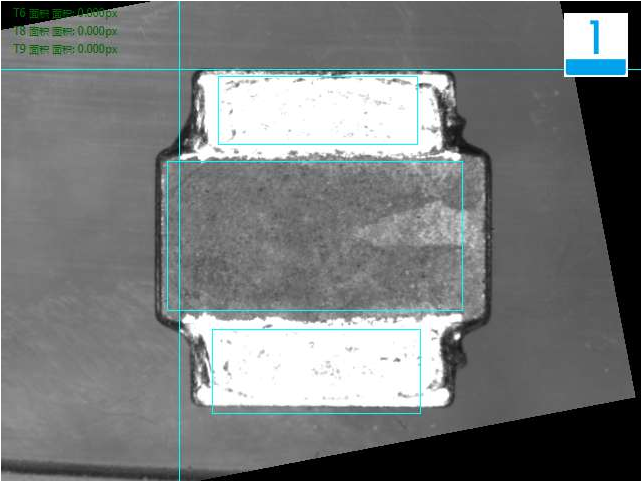

Bottom detection good effect analysis picture: OK

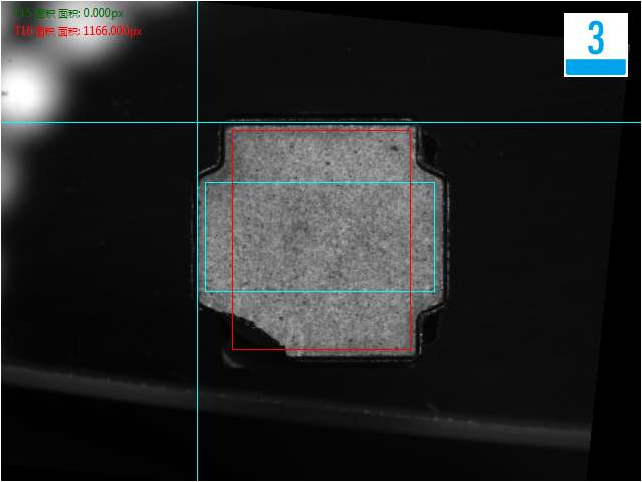

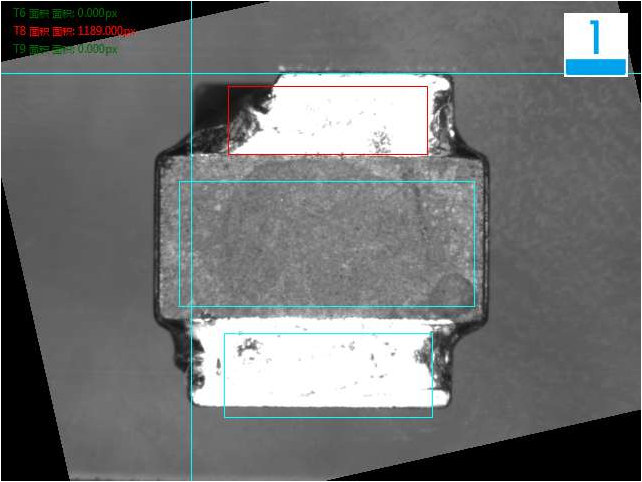

Bottom detect damage defective product analysis picture: NG

2. Top positive light detection method

Top detection effect original picture:

Top detection good effect analysis picture: OK

Top detect electrode damage defective product effect analysis picture: NG

3,4 side positive light detection method

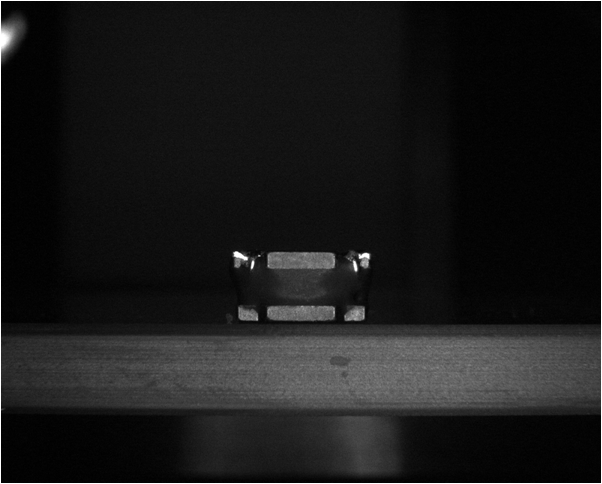

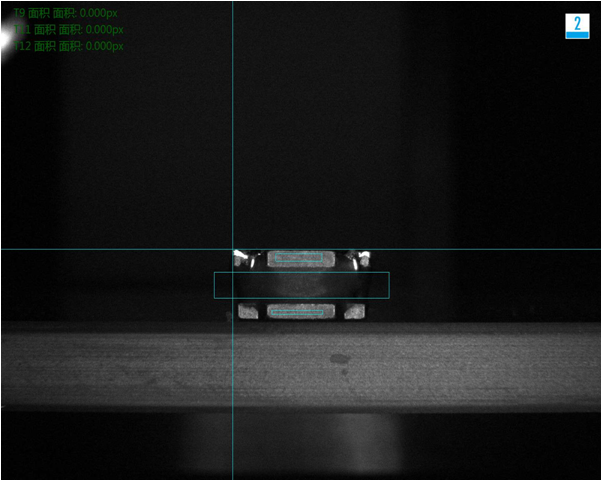

Side detection effect original picture:

Side detection good effect analysis picture: OK

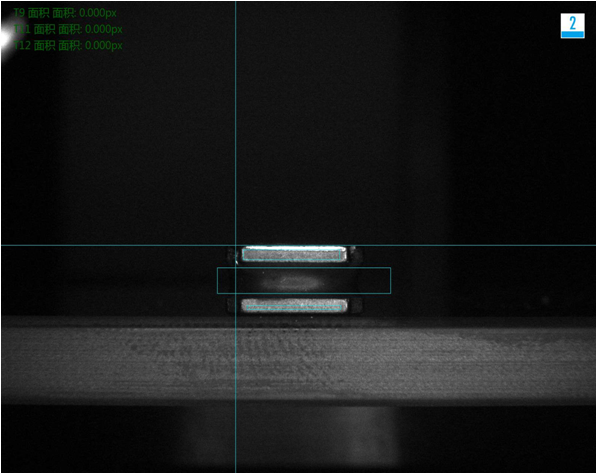

5,6 side detection effect original picture:

Side detection good effect analysis picture: OK

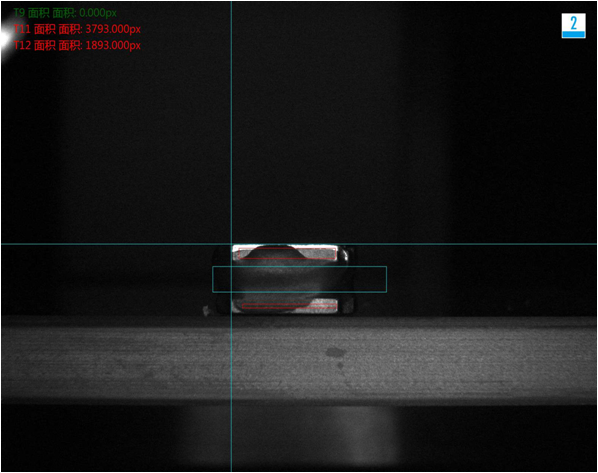

Side detection overfilled defective product effect analysis picture: NG

Ⅴ: system installation requirements:

Detection space for the machine placement: install the sipotek visual inspection system on the side of the pipeline alone. It need to assure there is enough space to install the machine.

Environment temperature: 0-50 degree Celsius.

Air humidity: 90% RH or less

Electronic interference: provide less electric interference place

Power supply: AC 220V, 50Hz, power consumption: less than 1KVA

For more information about inductance appearance inspection equipment, you can pay a visit to sipotek website at http://www.sipotek.net

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]