O ring, sealing ring, washer, gasket, are common objects for product sealing. Usually bad or failing o ring will produce a few symptoms and indicate a potential issue, such as fuel smell, liquid or gas leaking. Therefore, to guarantee the quality of o rings, manufacturers choose to use machine vision inspection to replace human check.

Sipotek Visual Inspection Machine 39

Understanding the common causes of o-ring failures will help a vision inspection solution company develop a more tailored machine to manufacturers. It has to be easy to control with high speed and high accuracy. The most common causes of the o-ring failures are like, improper gland design, too much or too little compression, not enough for seal expansion and tolerance stack-up, inadequate lubrication, etc.

How can we know the causes directly? The best way is by samples. Manufactures will have a data and record of the defects that indicate the degree of defects. The machines are tailored according to samples, so firstly, we will ask for defective samples for each model. A machine is compatible to inspection 2-3 different models. But a manufacturer may produce multiple models with different color, shape or size. And all manufacture want to use one machine to check all their models. We should let them understand the workable range and explain with a test report.

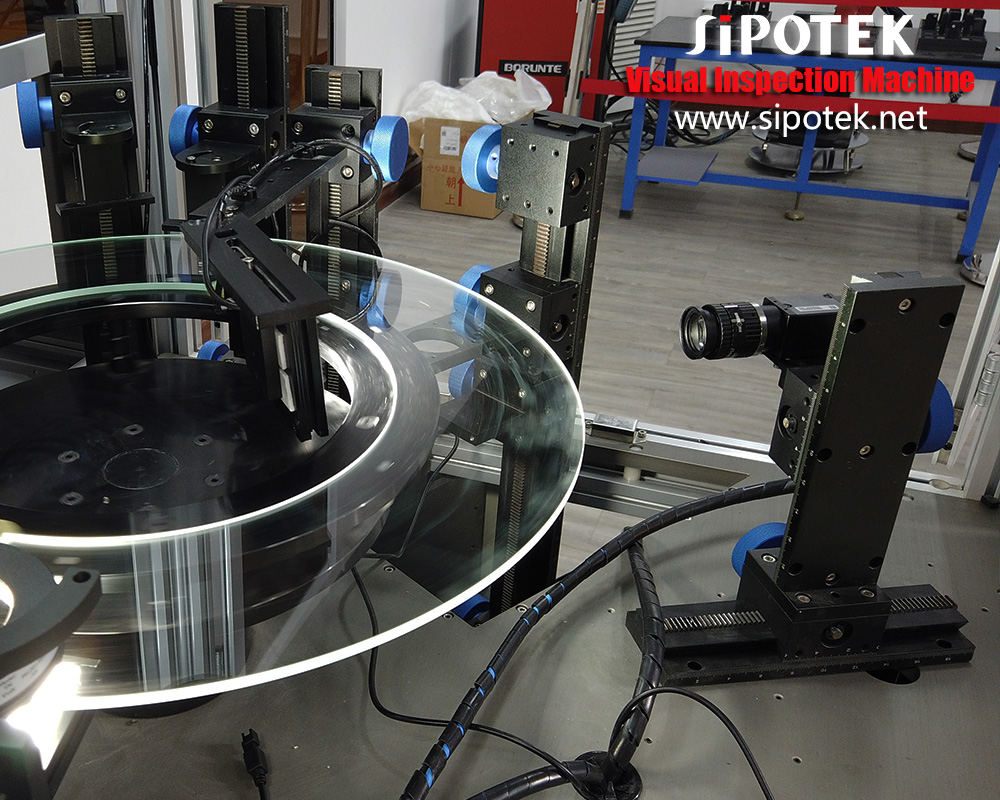

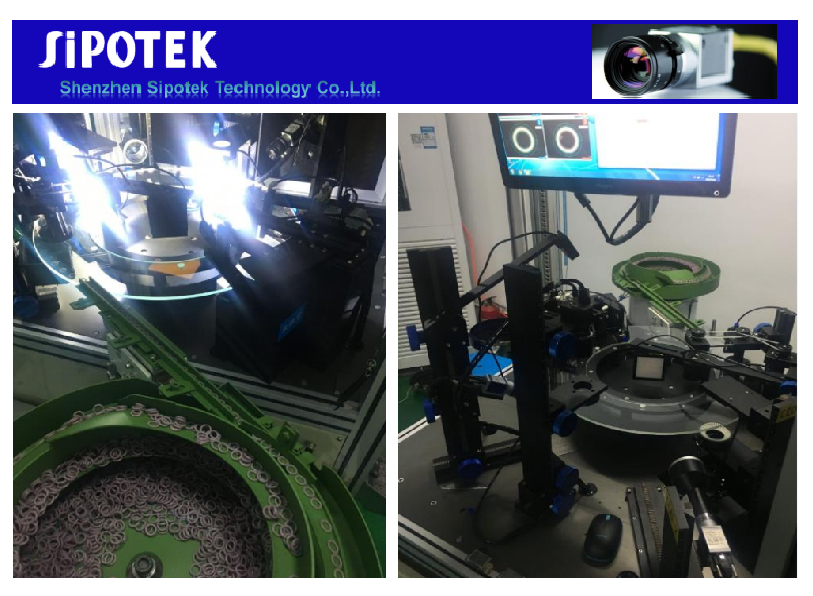

When we have the samples, the engineer will do a lighting test based on the defects. The core of the machine is the camera system and software processing ability. Our popular offline vision inspection machine is the vibration feeder type with a glass table for inspection. Around the glass plate, multiple cameras are set on specific positions. The work flow is simple. Input the products, camera takes photos of the product defects, system analyse the pictures and find the defects, take action to reject or pass by air blowing valve.

About us

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of machines vision systems for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-186-1718-2707

Email: [email protected]

Website: http://www.sipotek.net/machines/