We already know that machine vision is the technology and methods used to provide imaging-based automatic inspection and analysis for such applications as automatic inspection, process control, and robot guidance, usually in industry. What’s inside the machine vision?

- Image acquisition technology, the basis of machine vision

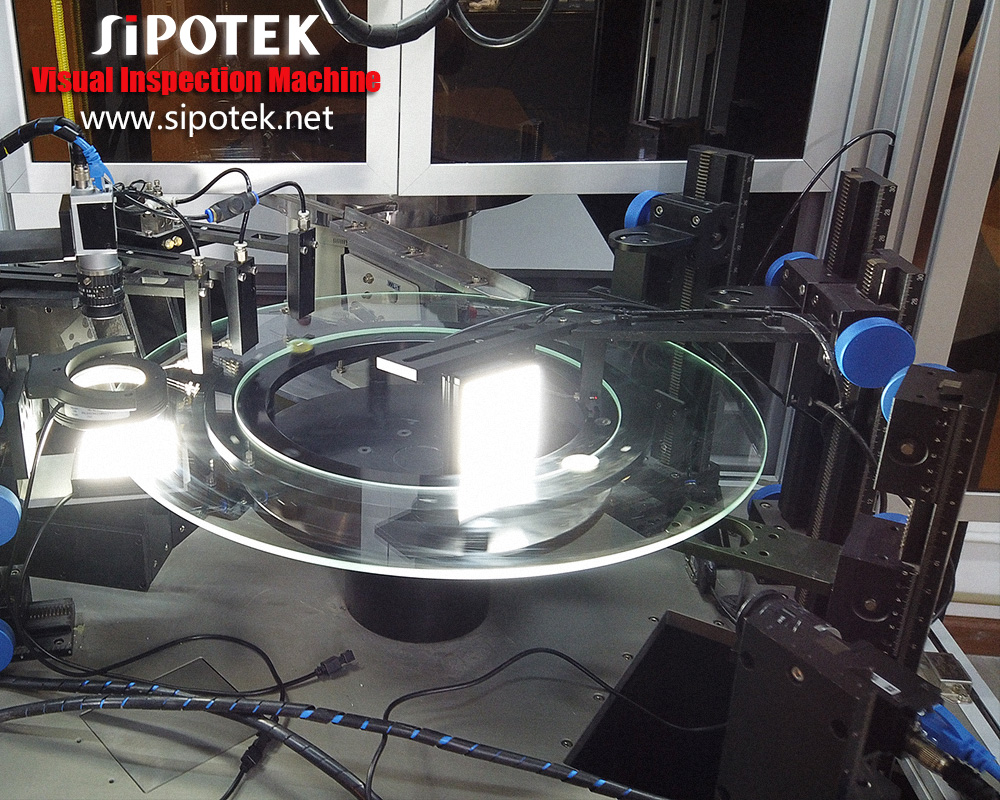

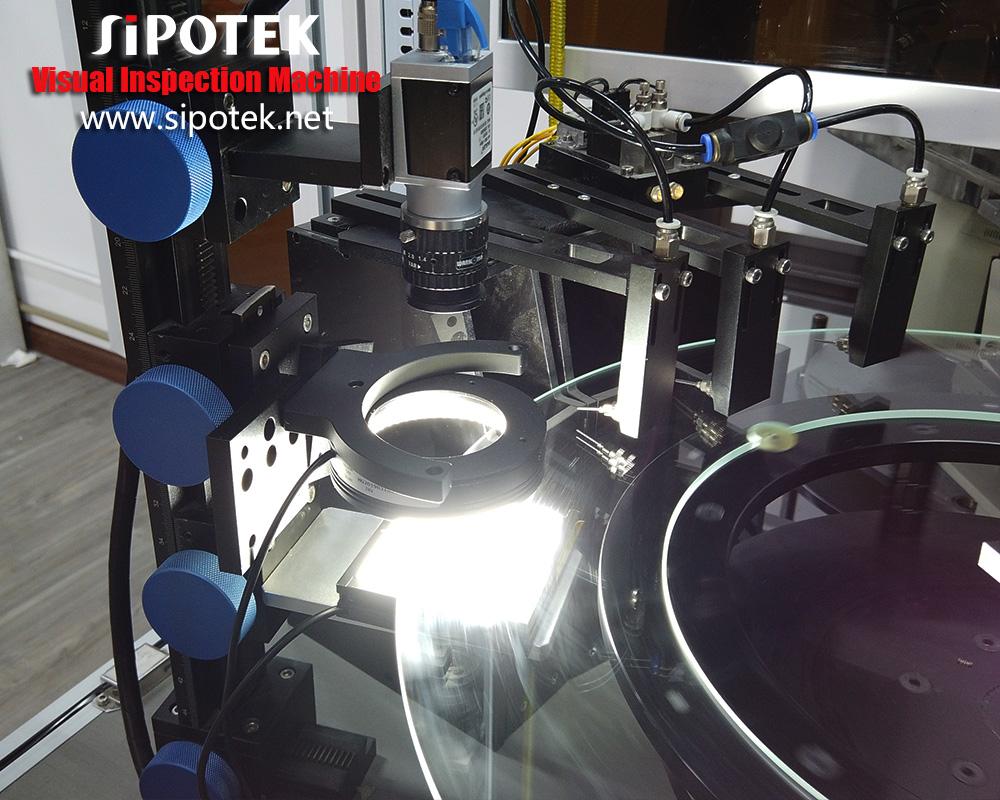

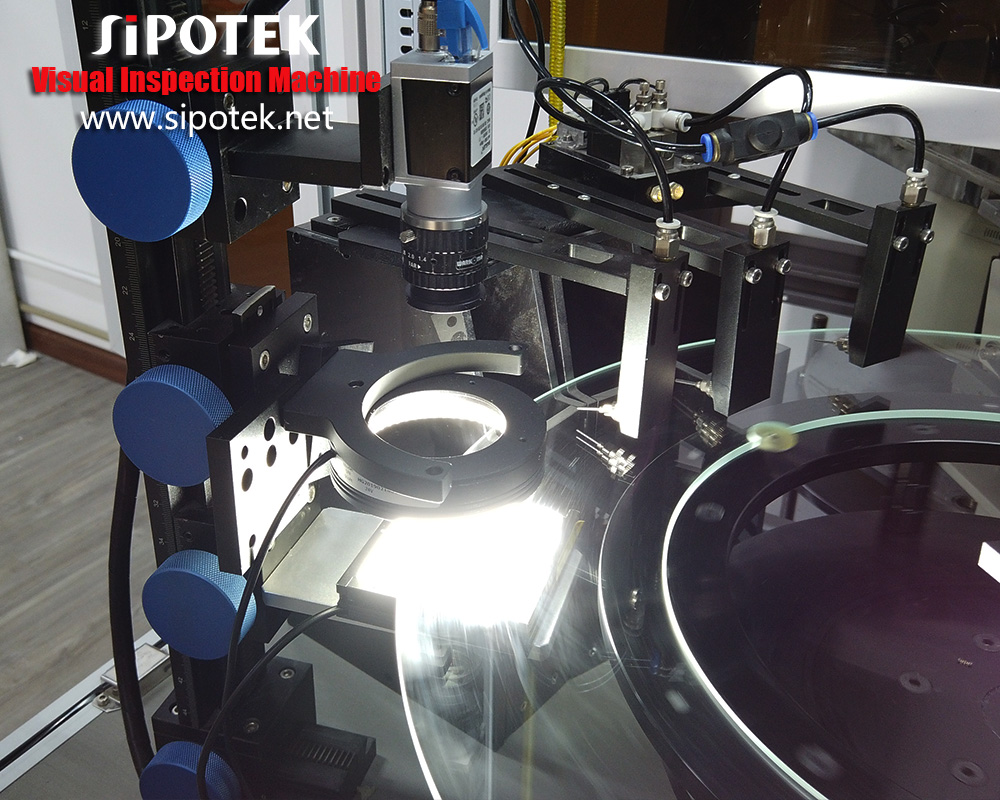

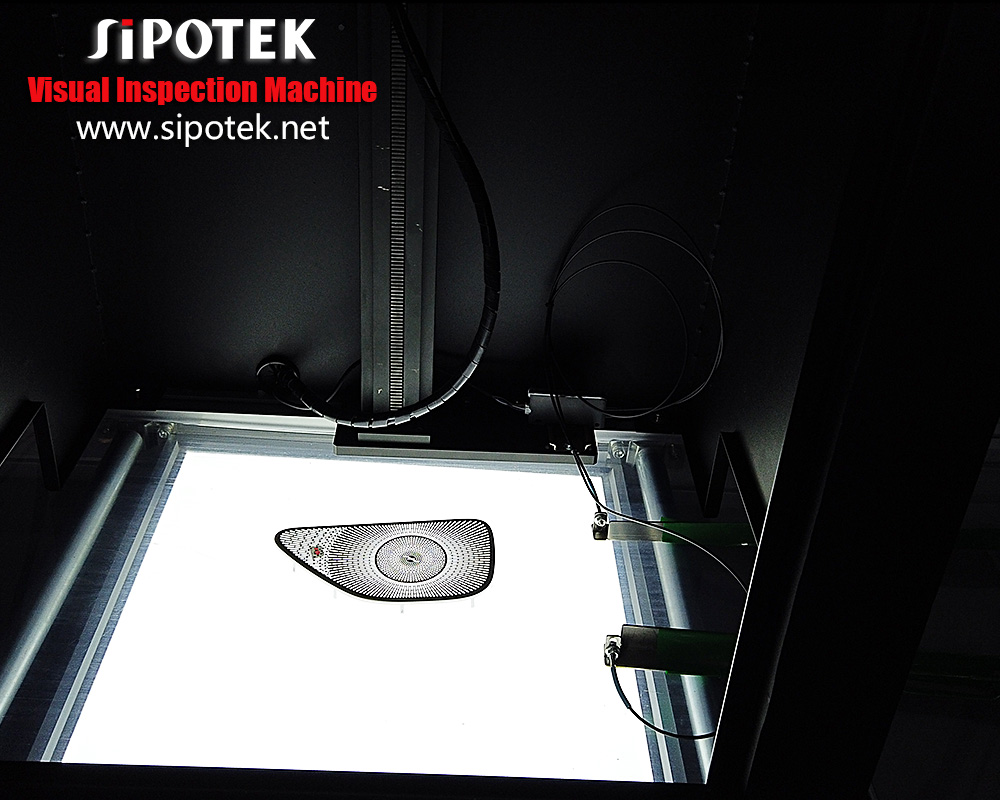

The image acquisition part is generally composed of the light source, the lens , the digital camera and an image capture card. The acquisition process can be simply described as the situation that with enough illumination of the light source, the digital camera captures the target and transmits it into an image signal, and finally transmits it to the image processing part through the image capture card. When designing the image acquisition part, there are many issues to consider, mainly about digital cameras, image acquisition cards, and light sources.

(1) Light source illumination

Lighting is an important factor affecting the input of the machine vision system, which directly affects the quality and application effect of the input data. So far, there is no machine vision lighting device that can be used for a variety of applications. Therefore, in practical applications, it is necessary to select a corresponding lighting device for the application to meet specific needs.

The illumination system can be divided into: backlight, forward illumination, structured light and stroboscopic illumination according to its illumination method. Wherein, the back illumination means that the object to be tested is placed between the light source and the camera to improve the contrast of the image. The forward illumination is that the light source and the camera are located on the same side of the object to be tested, which has the advantage of being easy to install. The structured light illumination projects a grating or a line light source onto the object to be measured, and demodulates the three-dimensional information of the object to be measured according to the distortion generated thereby. The stroboscopic illumination is to illuminate a high-frequency light pulse onto an object, and the camera captures the same requirements as the light source.

- Optical camera

The task of optical cameras is to perform optical imaging, which is generally used in measurement fields for measurement because it plays a key role in imaging quality. One problem that the camera needs to pay attention to is distortion. This requires the use of the corresponding distortion correction method, and currently people has also developed a number of automatic distortion automatic correction systems.

(3) CCD camera and image acquisition card

The CCD (Charging Coupled Device) camera and the image acquisition card work together to collect and digitize the target image. At present, the application technology of solid devices such as CCD and CMOS, linear array type sensitive devices, the pixel size is decreasing, the number of array pixels is increasing, and the pixel charge transfer rate is also greatly improved. In a PC-based machine vision system, an image acquisition card is an important device that controls the camera to take pictures to complete the collection and digitization of images and coordinate the entire system.

The image acquisition card directly determines the interface of the camera: black and white, color, analog, digital and other forms.

2, image processing and analysis – the core of machine vision

The core of image processing and analysis methods for machine vision is to solve the problem of detection and recognition of targets. When the target to be identified is more complicated, it needs to be realized through several links and from different aspects.

When identifying and extracting targets, the first thing to consider is how to automatically separate the target from the background. The complexity of target extraction is generally that the difference between the target and the non-target is not very large. After the target extraction scheme is determined, the target feature needs to be enhanced.

With the development of computer technology, microelectronics technology and large-scale integrated circuits, image information processing is increasingly done by hardware, such as DSP chips, dedicated image signal processing cards, and so on. The software part is mainly used to complete the part of the algorithm that is immature and complex, or needs to be continuously improved. This aspect improves the real-time performance of the system while reducing the complexity of the system.

For more information, vision our home page on www.sipotek.net

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/