What’s inductor?

An inductor is a component in an electric or electronic circuit which possesses inductance.

We also call is as a coil, choke, or reactor. It is a passive two-terminal electrical component that stores energy in a magnetic field when electric current flows through it. An inductor typically consists of an insulated wire wound into a coil around a core. The inductors are used to block AC while allowing DC to pass; inductors designed for this purpose are called chokes. They are also used in electronic filters to separate signals of different frequencies, and in combination with capacitors to make tuned circuits, used to tune radio and TV receivers.

How is it made?

In Inductor’s world, it introduces the manufacturing process of inductors in two types.

- Wire-winding type

- Core manufacturing – After the process of creating the fine particles, molding, and firing, electrodes are formed on the manufactured core (magnetic core).

- Wire-winding – A wire is wound around the core, and then terminals of the wire are connected to the core.

- Frame processing – The wire-wound core is sandwiched by the frame.

- Molding – Resin is poured over the coil sandwiched by the frame.

- Terminal treatment – The resin-covered coil is separated, and the frame is bent to form electrodes.

- Multilayer type

- Paste forming – Ferrite powder and resin are mixed to form ferrite paste.

- Sheet forming and printing – The ferrite paste is flattened into a sheet form, and electrodes are printed on it.

- Multilayer process – Electrode-printed ferrite sheets are stacked in layers and pressed.

- Cutting and firing – The stacked sheets are cut with a blade into the prescribed size, and perfectly fired in a furnace.

- Electrode coating and plating – Both ends of the fired coil are dipped in electrode paste, and then baked. Next, the entire body of the coil is dipped in plating solution.

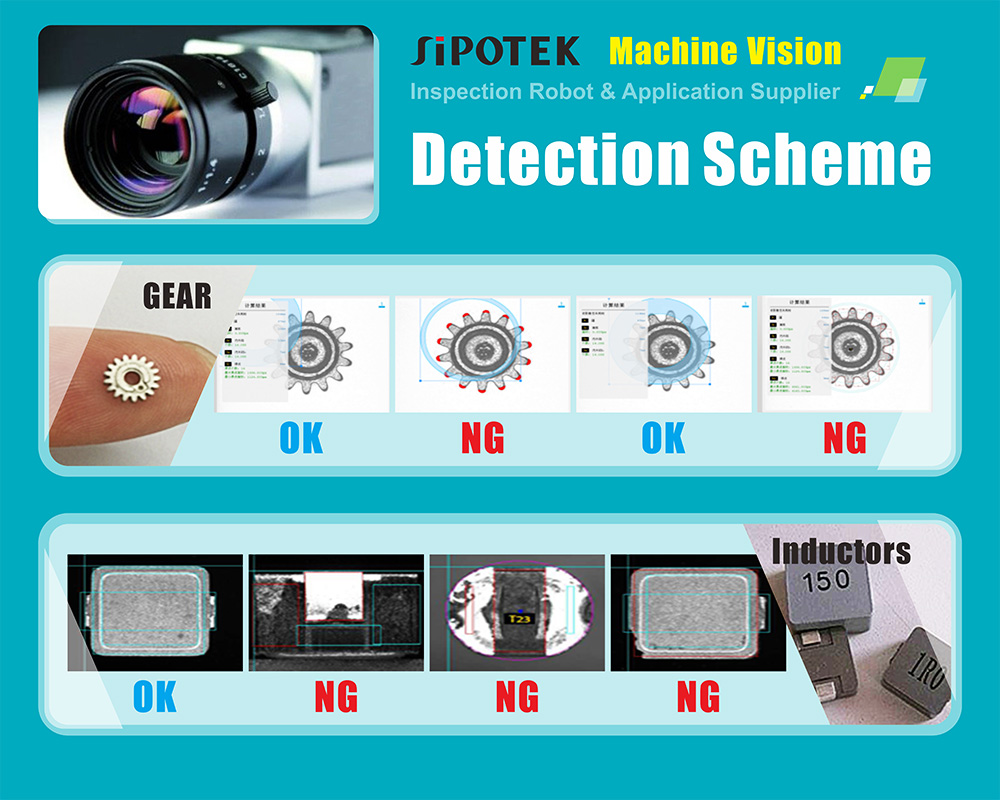

How is it inspected?

Traditionally, the dimension and surface defect are inspected by human eyes. However, the uncertainty percentage will be here when observing defects’ images through human eyes. In an optical sorting machine, there is an image system inside and the defects are easily captured by the industrial cameras and then be zoom clear.

Let’s introduce step by step of the process again.

- Prepare inductors that need to inspect. Make them ready to be fed into a special mechanism, take conveyor belt for instance. The inductors will run in a high speed in sequence one by one. Where they go? They will run one by one to the direct vibration mechanism, until they reach the glass rotary plate.

- Now it’s the glass rotary plate work. The glass plate will rote in a fast speed, onside which the inductors are standing still.

- The cameras are ready by receiving signal and they will be triggered to capture images of the inductors form specific sides.

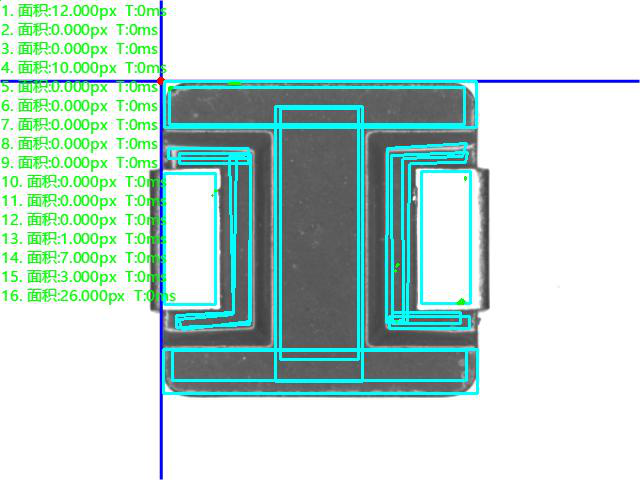

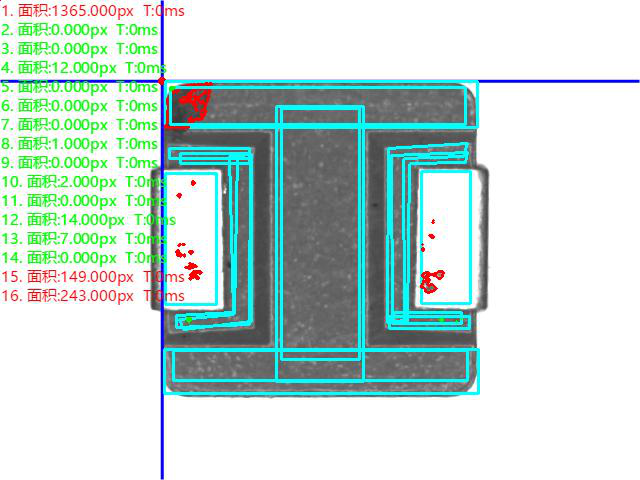

- The images captured will be transferred to digital signals and then transmitted to the inspection software system.

- The inspection software system will read the signals and make recognition with the template already set in the system. Such as the correct dimensions template for inspection parts, the tolerance data, etc.

- Now the software system has inspected the images signals, they will transfer the result whether it’s Negative or Ok. Then the machine system will lead the inductors being inspected, to the correct output channel. We call this processing, sorting or rejecting.

For more about machine vision inspection system,you can pay a visit to sipotek website at http://www.sipotek.net

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]