CCD visual inspection equipment has several unstable factors when inspecting products, which will cause a great impact on inspection accuracy and efficiency. The following are unstable factors during the detection of CCD visual inspection equipment.

Industrial cameras are the main image processing tools. Usually in the market of vision inspection, we divided the equipment model by either CCD vision inspection , or CMOS vision inspection. They are the two

For CCD visual inspection equipment, the selection of industrial cameras takes into account its sensor type, pixels and frame number. Among them, the controller is divided into two types: CCD and CMOS. CMOS optical lens has high processing speed, and the middle distance between various components and power circuits is close to each other. The impact is serious, and the imaging noise is high. Compared with CMOS cameras, CCD controller cameras have the characteristics of high sensitivity, low noise, and fast response time. In terms of stability, CCD cameras are also more resistant to shock and vibration. General speaking, CCD controller cameras are better than CMOS cameras in terms of image quality and stability.

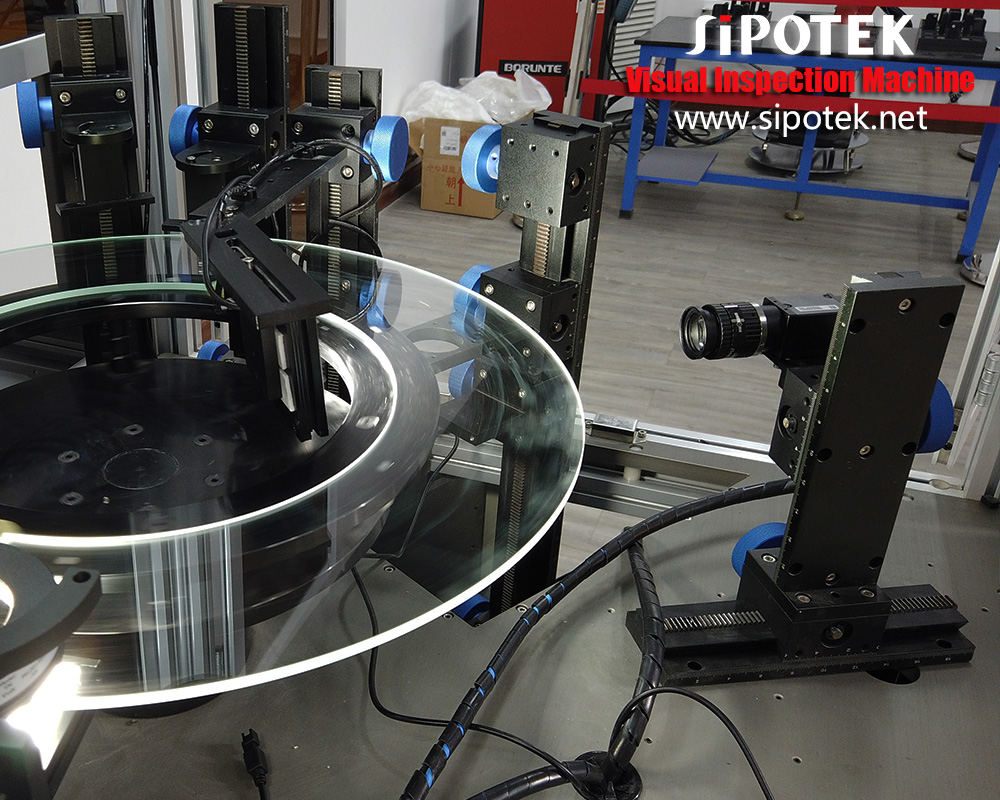

Sipotek Visual Inspection Machine 39

Another key factor that affects the camera’s imaging quality is the camera’s wide-angle lens. In addition to the wide-angle lens and the main parameters such as the focal length, a key factor affecting the accuracy of network detection is the image. The geometric deviation of the geometric shape cannot be cleared, and only the filling can be filled. Although many industrial cameras now fill the deviation caused by the wide-angle lens variation according to various methods, in the high-precision inspection industry, the geometric shape still affects the inspection accuracy.

Sipotek Visual Inspection Machine 25

At Sipotek, we use SONY industrial cameras with CCD controllers and provide our customer a more stable and feasible solution on industrial applications

About Sipotek

Shenzhen Sipotek technology company limited was established in 2002 and its main businses is machine vision automation system and complete equipment. The company has formed a team with 12 senior personnel on machine vision system and industrial automation engineers. Our targets customers are from industrial of precision hardware parts, electronic components, rubber silicone parts and etc. We provide both online vision system for vision engineers and complete machine for offline inspection for manufactuers.

Sipotek is committed to becoming a leader in visual inspection field, creating values for customers. We provide visual inspection solution with free charger. If you have quality issue, you can consoult us by the following:

For more information,

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-18666216027

Email: [email protected]

Website: http://www.sipotek.net/machines/