As human beings, we know that failure in certain situations can sometimes be quite a stressful task and that the consequences brought by this could vary and translate into slight or severe damage to the company that owns it.

If you are an entrepreneur, especially a manufacturer of certain products, it is known that an error in production could cause certain inconveniences that at the end of the day would result in monetary losses, which is to be feared for all people who work in a company.

The manual visual inspection, caused some monetary losses for multiple companies.

Previously, when there was not even a machine vision inspection system manufacturer, any failure that was not determined in a normal visual inspection, was of course the fault of the operator who was engaged in doing this work, and the process was much slower; as a result of this, the companies faced some unexpected losses, which clearly did not make their members very happy.

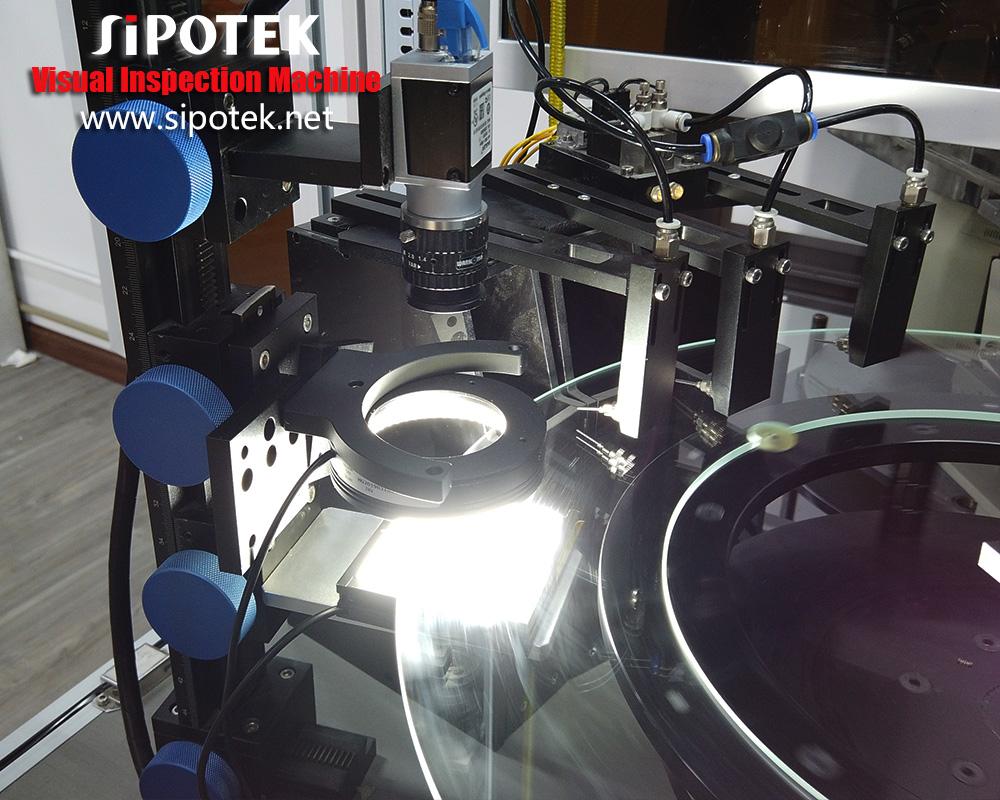

The first machine vision inspection system manufacturer completely revolutionized the forms of production.

The need to do this work quickly and accurately, led to the emergence of the first machine vision inspection system manufacturer, who would completely transform the way they had been manufacturing products in large quantities.

Going to a machine vision inspection system manufacturer did not guarantee that all products that emerged from the company were in perfect condition, but thanks to a quick review of a large number of these, you can easily determine the most common mistakes and this form can be attacked in time to be modified from an initial point of production.

What happens if a system fails, should the machine or the machine vision inspection system manufacturer be held responsible?

It must be thought that it is natural that at some point a system may fail, leading as a consequence that material considered defective should be discarded for not complying with the basic standards that the company provides to consider an object as suitable for use. However, it must be understood that in all machines there may be a margin of error, this may be minimal in the case of companies that manufacture the highest quality visual inspection machines.

All this can present some inconvenience in the production of some object, however, we must also take into account that any error that occurs not only can be carried to the system that the machine possesses, but also we must consider other aspects, for example, the light that affects the image of the object that is considered perfect just when the database is being filled with the information that will serve as a reference for the other images of the rest of the products.

This can be a mistake that can not be directly credited to the visual inspection machine, since it will take the test images as the highest level of comparison, and any product that is very similar to this will be considered perfect.

For more about machine vision inspection system,you can pay a visit to sipotek website at http://www.sipotek.net

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]