Automation technology can not only increase manufacturing efficiency and yield, but also reduce waste, accelerate time to production, and most importantly can improve safety in the plant.

Before 2003, the founder of Sipotek was the chief director of product quality department for Philips China region. He was one of the professional personnel in the machine vision industry of China. After he left Philips China, he established Sipotek in Shenzhen and put it’s core in the development and application of the visual industry.

With 16 year development, Sipotek now has 70 senior R&D personnel of machine vision system and the industrial automation engineers. Our key technical personnel are mainly from first-class like Huawei, BYD and Foxconn manufacturing enterprises. With many years of mature experience in software design, visual and image comparison technology, industrial automation and other machine vision aspects. In 2018, the company was honored to be the general deputy of SONY industrial cameras in China southern area. At the same year, Anhui branch was established to provide better service for eastern market. Through many years of machine vision equipment designation and manufacturing, the system and equipment produced by our company have been well applied by many international renowned companies such as Midea, Foxconn, Chery Automobile and BYD etc.

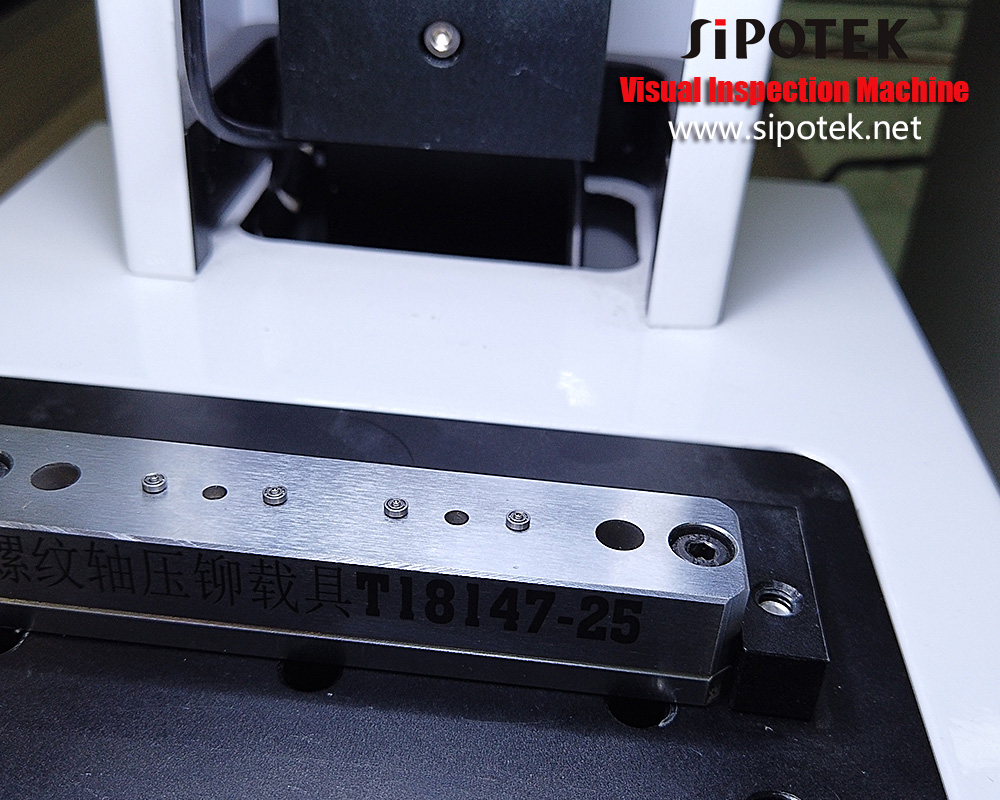

There are three main techniques developed by Sipotek, dimensional measurement, external appearance and inner view measurement. The company now has reached the dimensional measurement with 0.003mm accuracy. For appearance detection, the company has a wider range of surface scratch, wrong color, burr and flash. The leading technique is line scan and inner view measurement. During many years research in machine vision, Sipotek has gained many invention patents and copyrights such as machine vision size measurement software, upper dip detecting device and tape and reel product visual inspection equipment.

“Improve safety in your plant” is the concept we hold. In traditional manufacturing plants, workers are staying at the production line more than 8 hours a day during the pre-production production and post production processes. Thanks to automaton development, the machines help workers to operate the production automatically with efficiency in more safely conditions.

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/