Macine vision is a common technology using in manufacturing process. In pre-production, vision inspection machine can check the materials being mixed or uncertain if they were size corrective. In post-production, vision inspection system can connect to the production end and inspect the end products to a 100% qualified. Machine vision inspection in its way helps companies and manufacturers provide a trustworth quality for their target customers while increasing the productivity and reducing the labor cost. However, before a factory put into use the machine vision inspection systems, there are some general concerns and doubts from decision makers:

- My orders are unstable

- Let’s wait for a second

- The price is too high

- Human inspection is still working

What are the benefits when using automated optical screen sorting machine?

- As for the unstable orders, we need to considerate more about the reasons. When you find there is no problem in materials and production process, you will only concern about quality aspect. Most of the time customer will stop cooperation while quality problem happened. We need to guarantee quality so that customer will have faith with your products and keep a long term business.

- Time waits for no man. Waiting gives less chances for business. When you hold your speed, wait and see, your orders are placed by other business competitors already. It’s late when you hesitate whether you should update your inspection process.

- Cost is the basic element of every product. Nowadays there is no huge profit in practical industry. We have to concentrate on not only the price, but the value of the product it can make. When you choose an optical screen sorting machine, you will firstly check its business qualifications and hardware configuration. And the software must be self-developed. Some optical screen sorting machine companies use purchased software system, their future upgrading is limited. Our self-developed software gives no worries about upgrade. You can check on-site in company and see if the sorting solution meet your requirements. You will find there is a large potential in optical screen sorting machine.

- Human inspection is traditional in manufacturing industry. Cost of labor source is a big problem. Quality inspection will be influenced by human subjective emotion and fatigue. The efficiency of the quality can not be guaranteed. It happens that good parts will mix with negative parts. It’s important to ensure the quality and deliver orders on time.

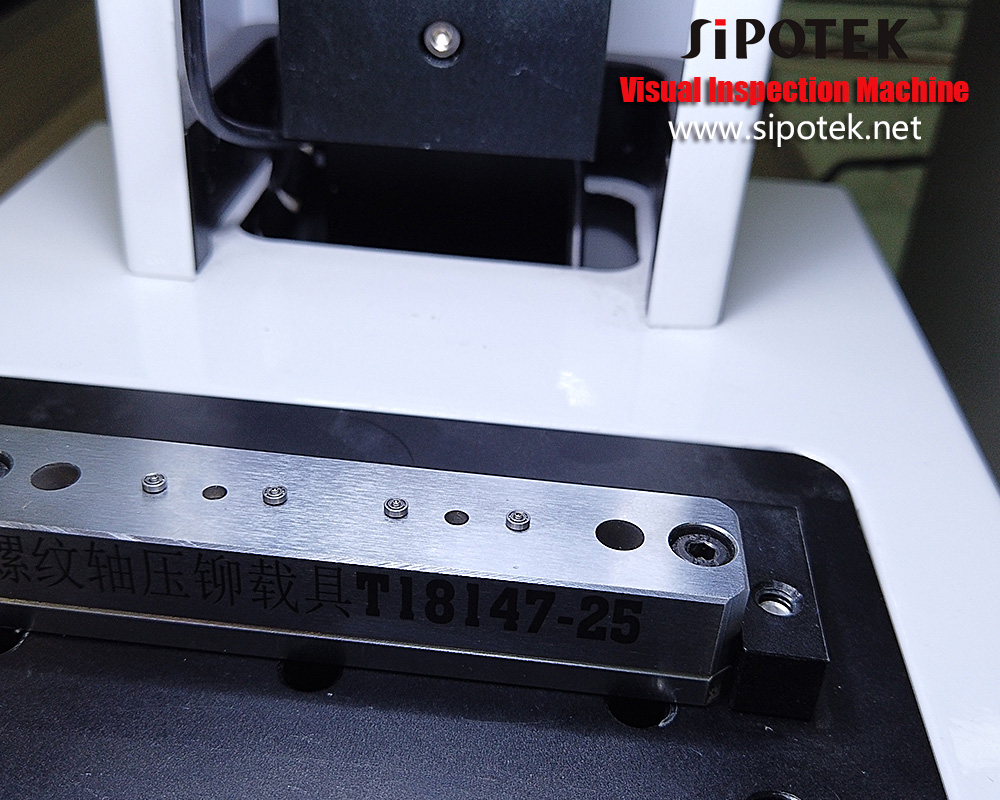

Established in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: +86-18617182707

Email: [email protected]

Website: http://www.sipotek.net/