Defects inspection ensures product quality

To replace manual inspection with machine vision technology in factory production line, to check the product real-time status all day long. To prevent the unqualified products from being discharged because of human fatigue. At the same time, it can save the labor cost and improve production efficiency for the manufacturing enterprises.

At present, machine vision inspection is mainly applied to the field of online external inspection, data acquisition is performed by machine vision image collect system. Data analysis and parameter storage are performed by machine vision software.

Pharmaceutical industry packaging inspection

In recent years, the competition in pharmaceutical industry market has been especially prominent. No matter it is in China, Germany, Japan or other country, there are different pharmaceutical standard. It will require extremely strict check from medical production, packaging, transportation of pharmaceutical. Here we will take the label inspection of vial power bottle alone for interpretation.

Vial power medicine production procedure is pack the power medicine into the glasses screen and cover it, then stick label, pack and package. The whole production is automated machine production process. In the automatic labeling inspection step, often because of the label machine problems or the label stickers are not be replaced in time, the labels on the medical bottle are leaked or post beyond the bottle. In the traditional manual inspection, often because of the production speed is too fast(three bottles per minutes), visual fatigue which causes the missing detection, resulting in abnormal label shipments of medicine.

Artificial intelligence, edge computing, internet of things are not a new concept. High speed technology innovation will be quickly improved with the domestic machine vision, strength fact in China and augmented reality.

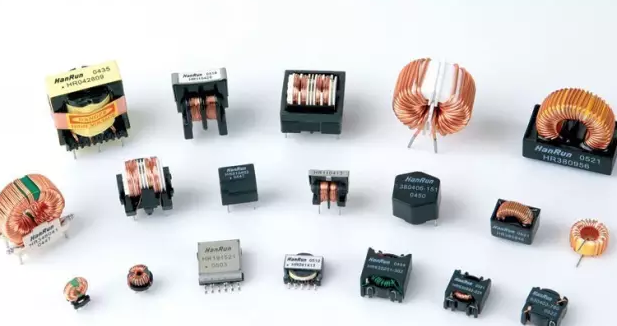

Manufacturing field equipment maintenance forecast

The popularity of automated equipment has replaced more man power, but it is inevitable that each equipment component service life, which requires supervision and maintenance, etc. The factory delivery time, production schedule will be delayed by a often sudden equipment failure. It will serious affect the customer trust or terminate cooperation.

At present, AOI machine vision plays an important role in the predictive and maintenance of equipment. By real-time inspecting and comparing analysis of the equipment important part, it is estimated that the equipment part are damaged and usable, which remind the relative equipment manager to spare, replace in time.

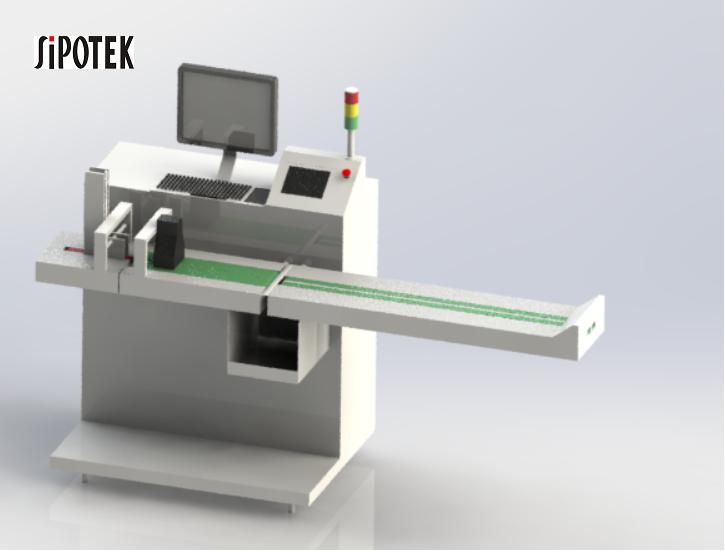

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/