Automated Optical Inspection Machine Vision System of Sipotek uses machine to replace human eye to make various of Machine Vision Measurement and judgement. It is an important branch of the computer subject which integrates optical, machinery, electronic, computer hardware and other technology. It refer to computer, image processing, pattern recognition, artificial intelligent, signal processing, optical mechanical and electronic integration and other industries. The rapid development of image processing and pattern recognition has promoted the machine vision application.

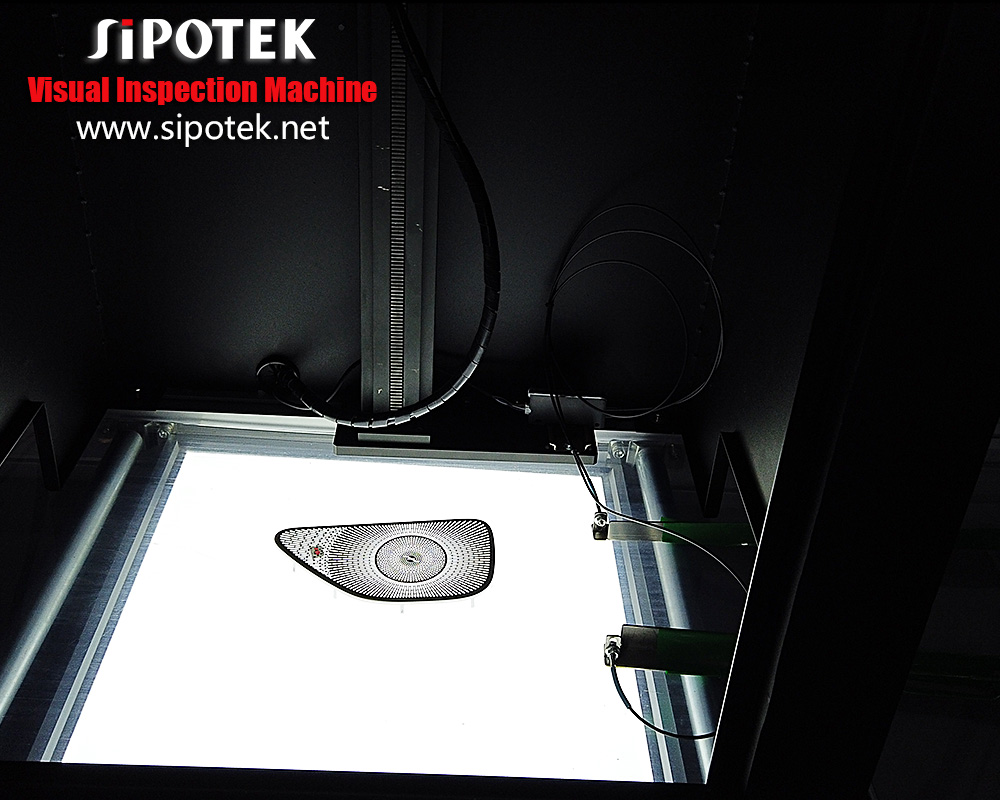

Machine vision system is called industrial visual system which principle is to image the products and area, then use the specific image processing software to process according to the image information. Software can automatically judge product position, dimension and appearance information according to the processing results and judge the qualified and unqualified products base on an artificial presetting standard then output the judgement information to the execute mechanism.

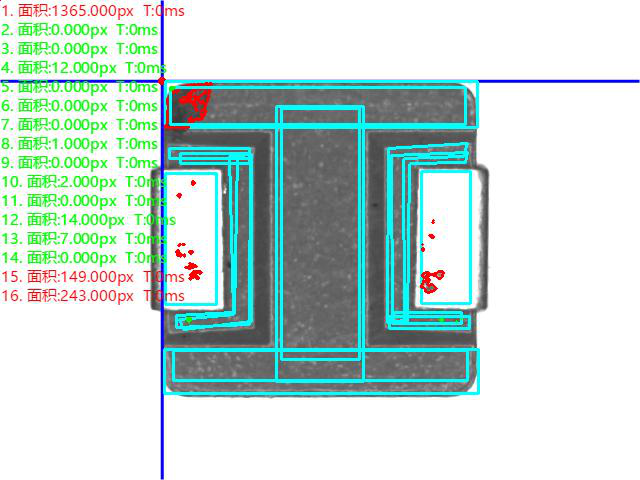

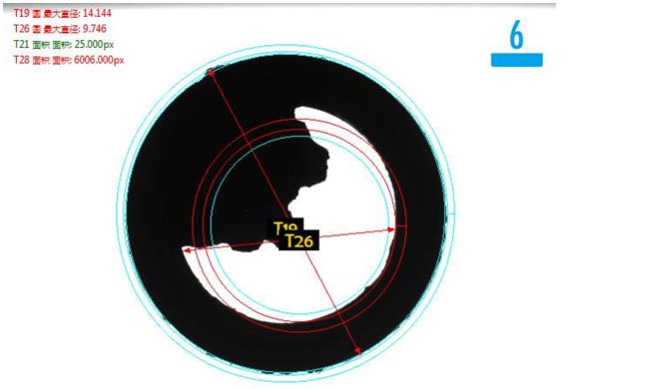

Machine vision inspection system converts the inspection objects into image signal, transfer to the specific image processing system. Base on the pixel distribution,brightness, colors and other information transfer into change into digital signal. Image processing system can make various of calculation to extract the character of the target. For example, area, quantity, location, length, according to the presetting permissibility and other conditions to output the results, include size, angle, number, qualified and unqualified, with and without to realize automatic identification function.

In terms of functions, machine vision system has three major functions: the firstly is positioning function which can automatic judge the interested objects, where is the products located and output the position information through a certain communication agreement. This function mostly use to fully automatic assembly and production. For example, automatically assembly, automatically welding, automatically packing, automatically filling, automatically spray, mostly match the automatically perform mechanism (Robot hand, welding gun, spray mouth). The second function is measurement. It can automatically measure the product appearance dimension, such as appearance contour, bore diameter, height, area and other measurement. The third is defects inspection function. This is the mostly use function of visual system. It can inspect the related information of product appearance. Such as package visual inspection, packing visual inspection, printing visual inspection, scratch or grain on the surface, damage, oil stain, ash, whether the plastic product are perforated, bad injection visual inspection,etc.

Compared with artificial or traditional machinery way, machine vision system has fast speed, high precision, high accuracy and a serious of advantages. With the development of industrial modernization, machine vision has been widely used in various of field, provide better wonderful product quality and perfect solution to company and users.

For more information, vision our home page on www.sipotek.net

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/