It’s known to all that the mobile phone assembly screws are very tiny ones, only with dimensions about 1-3 millimeter (mm). And their shapes are different from pentalobe, cross, tripoint and most are special shapes for different phone brands.

Society’s demand for high quality mobile phones today has influence the same requirement even for a tiny screws inside. Even a small screw problem will affect the completed for a qualified mobile phone assemble. When you choose our Sipotek team, our talented engineer and software developers will tailor the machine we prepare for you specifically to your needs. Our goal is to help you only produce the best products to ensure a standard of quality across all of your products.

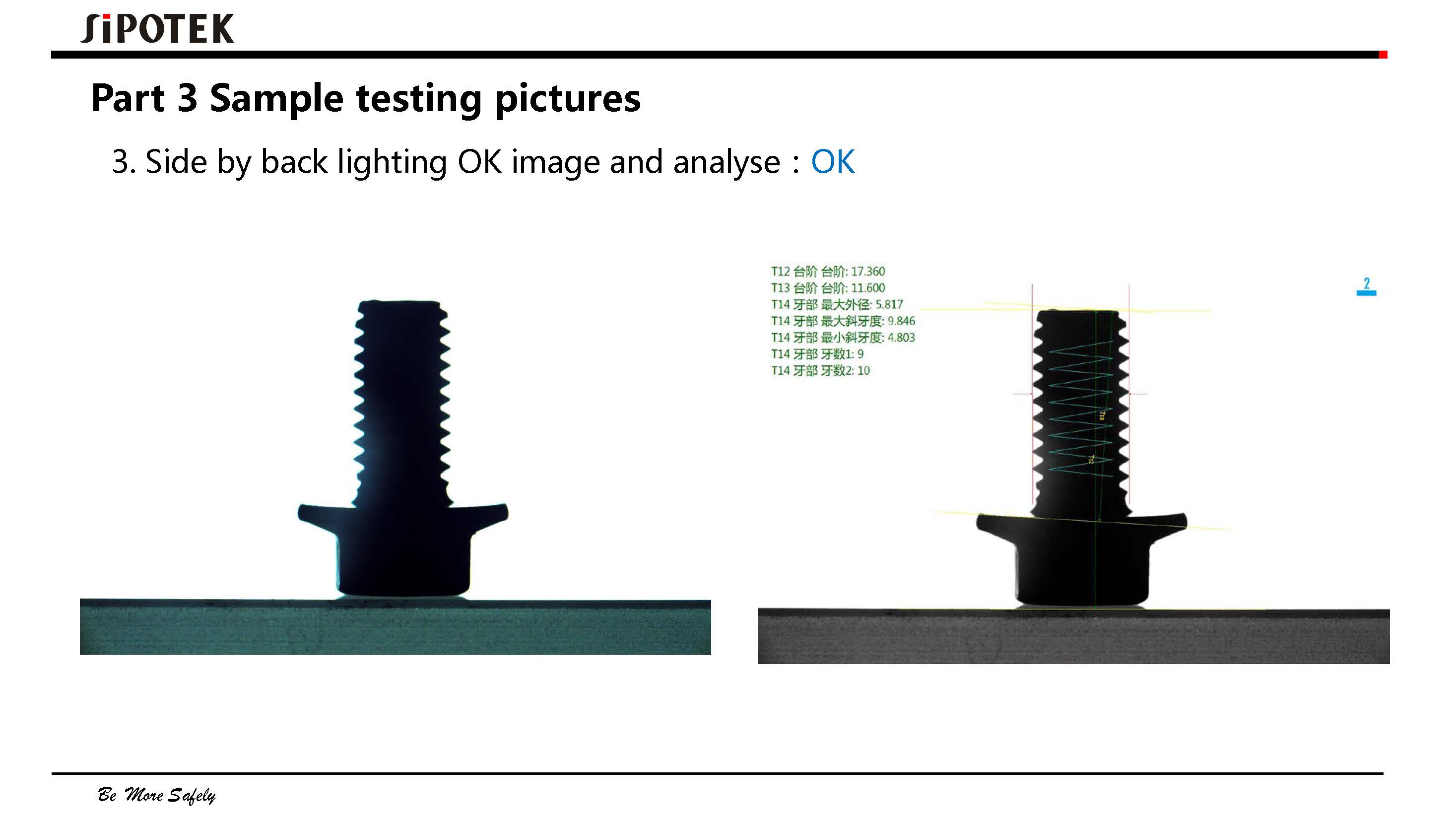

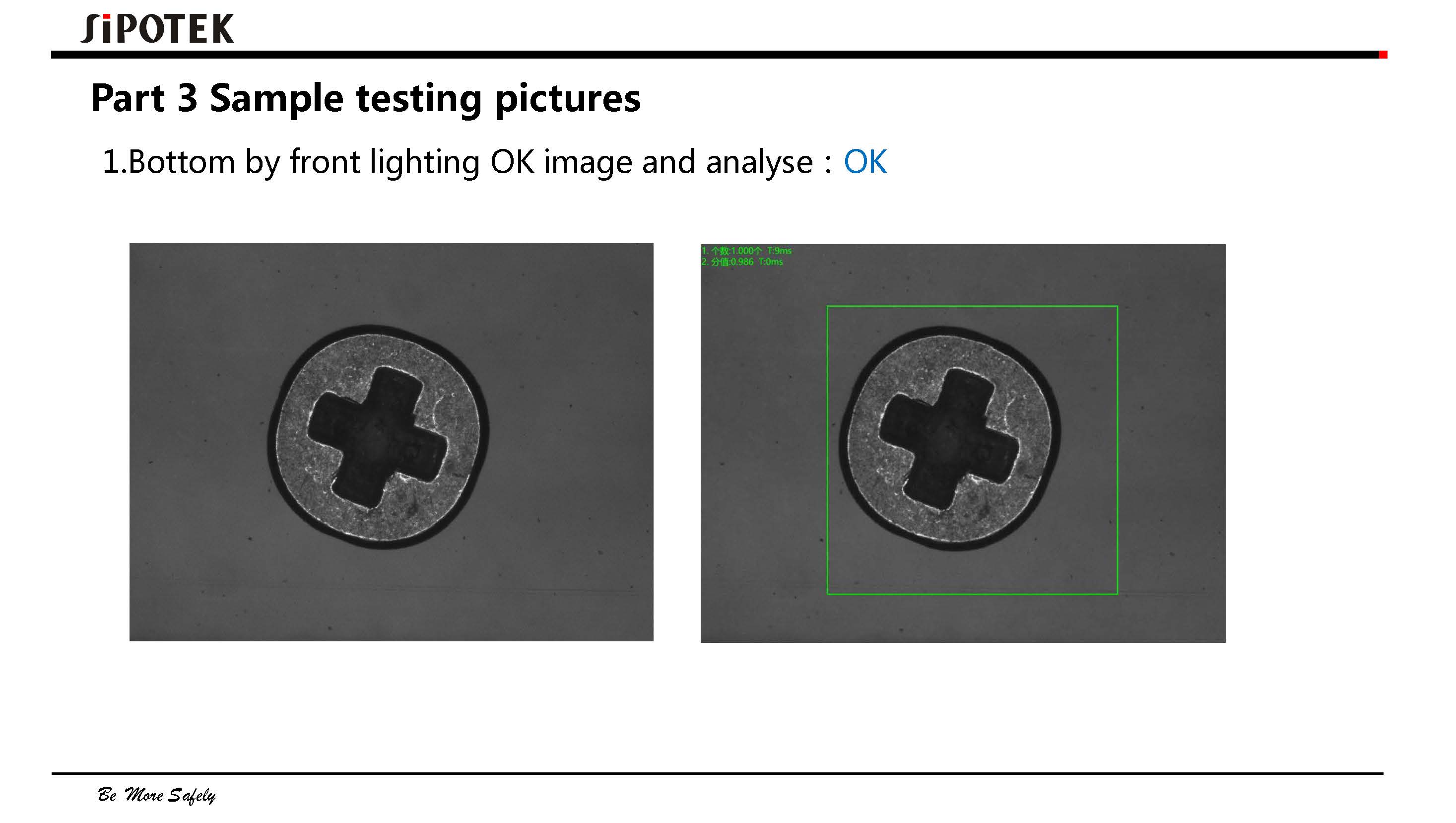

There are different types of visual defects or dimensional problems for mobile phone screws. On dimension aspect, head diameter, shoulder diameter, total length, head height and etc. On surface defects, head formation and corrosion, rust , crack and etc. Our solution is tailored for mixed screws bulk. Totally there are three process for the inspection.

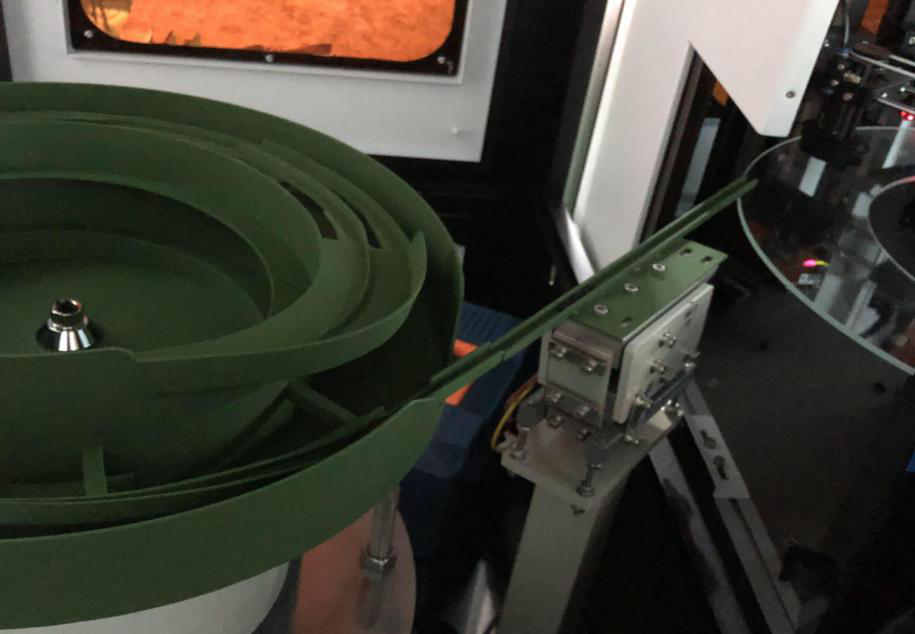

First process, the operator human feed the mixed screws into the vibration bowl feeders. Open the machine, the vibration bowl feeder is working and rotating. The screws will be transported one after one closely to a direct chute waiting to go to next station. That’s the feeding mechanism.

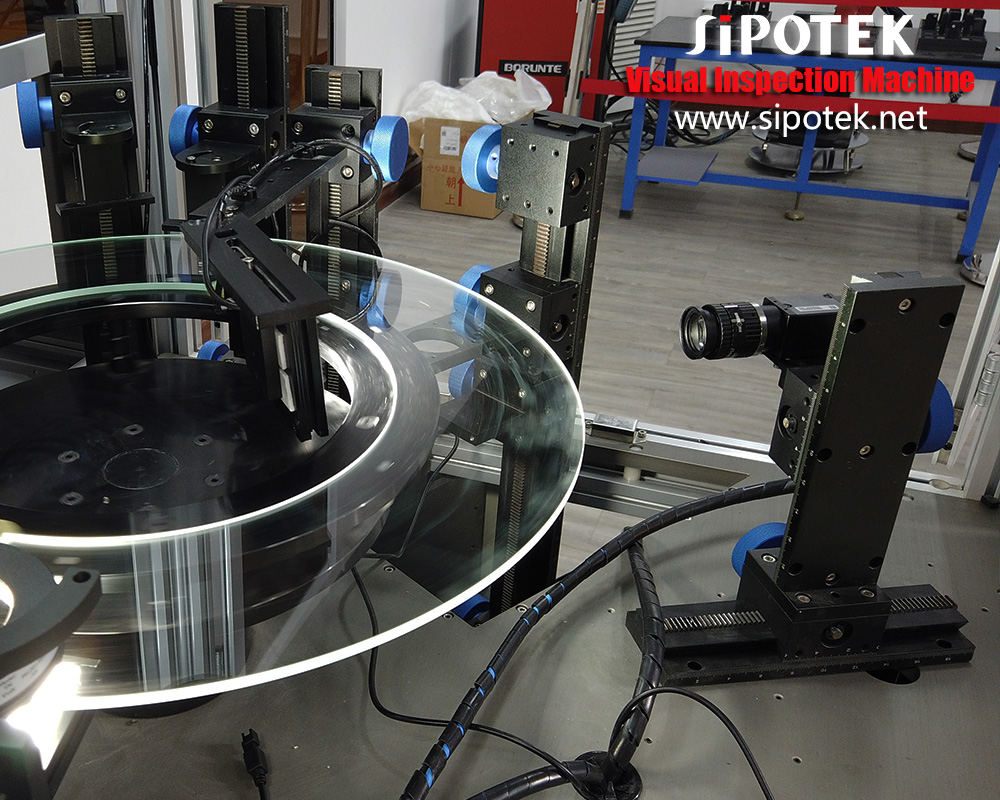

Second process, the waiting screws are going to a professional glass rotary plate. Now the screws are lying on the plate waiting for inspection. If the automated vision inspection system identified that a screw is with wrong dimensions or defects that we predetermined set in our template tool, the system can trigger a process fro this screw to be directed to a different path and straight to reject bin.

Third process is closely connected to second process. It’s the rejection and sorting mechanisms. While NG screws are rejected to NG bin, other Ok screws on the other way, will also be lead to the Ok bins so as to complete the sorting and inspecting. The sorting output is also tailor designed according to customer requirements. Currently we can have a maximum quantity of 6 outputs in a machine.

Each process are predetermined by the system. Before the system works, we need to make a lighting test for samples. And this is the basics step for our engineer and software developers to design the system. We can summarize that the automated vision inspection system utilize a single inspection system with multiple cameras including multiple vision module to acquire a top view, bottom view or a side view images and multiple high resolution mega pixel cameras with structured lighting source to acquire necessary images and inspect the problems we need. In this way, we provide our customers not only accurately, but also quickly and objectively visual inspection systems cater to their production lines or products.

Sipotek focus on machine vision robots for over 16 years. Send us your requirement, return to you will be our inspection solutions!

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/vision-solutions/