Machine vision technology is not only utilized in the end products quality control process, but also can be used to detect texts, characters, codes on some printing products like cards, cloth tags, stickers, labels etc. Sipotek automated optical inspection machine has its core system composed by SONY industrial visual system. Why does this system becomes the core composition and how does it work?

The range of system application

- Guidance of carry and installation. All known as visual positioning

- Online technical inspection on production process. To diagnose missing or not when loading, and mixed materials with marks respectively.

- Online packaging inspection. To detect whether anything is missing during packaging, to count the quantity.

- Printing label inspection. To read and to distinguish.

- Tracking and recording products. To track and read product barcodes or 2D QR codes.

- Online real time quality control. External appearance inspection, dimensional measurement.

Introduction of 8 functions

- Position guidance for product contours image, edges, angles, central of the circle;

- Category recognition for image distinguish, outline of the products, inspection whether there has the target or not;

- External appearance inspection for flaws, defects, dirt;

- Visual counter for outline counting, block counting, image counting;

- Recognition and reading for barcodes and 2D codes;

- Geometric measurement for length, width, circle, dot, line, angle and radian;

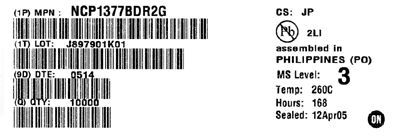

- Printing inspection for wrong printed, missing printed and printing oil trace;

- Character recognition for English text, numbers.

Application case illustration

The case is about character printing quality inspection by a visual controller, including the printing position and printing defects. When using the Sipotek visual inspection system, a parameter of the qualified product need to be set. The inspection work will take reference of this parameter and make decisions on whether the inspected is good. In the course of inspection, the products will be carried to a specific place where the camera is ready to capture images. When will the cameras start? The visual controller will get a signal from PLC when the objects was on the camera capturing spot. The visual controller then send the signal as a trigger to the cameras. The inspection process will be very fast just after the image processing process. The main two process of the visual controller is the trigger mode and the signal feedback mode, which are both can be customized.

For more about machine vision inspection system ,you can visit to our website at http://www.sipotek.net

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]