What will an MV (Machine Vision) system be applied in quality control process? How an small products like rubber stoppers, silicone caps be inspected through an optical inspection machine?

Rubber products are very flexible and broadly used in pharmaceutical industry. A variety of caps that used to seal medicine vials are made of rubber. We called them pharmaceutical closures. It was also known as stoppers, bungs and plungers, are an important part of the final packaging of pharmaceutical preparations, particularly those that are intended to be sterile. The most commonly used type of stopper is the elastomeric closure. An elastomer is any material that is able to resume its original shape when a deforming force is removed. The function of container-closures is to keep the contents of pharmaceutical preparations sterile by providing a barrier between the neck of a vial and the vial contents. Therefore, the manufacturers and users must have confidence in the quality control and validation of closures. It is an important part of pharmaceutical manufacturing that all stoppers are qualified enough to protect the medicines or liquids in the vials thus the inspection process becomes quite important and necessary.

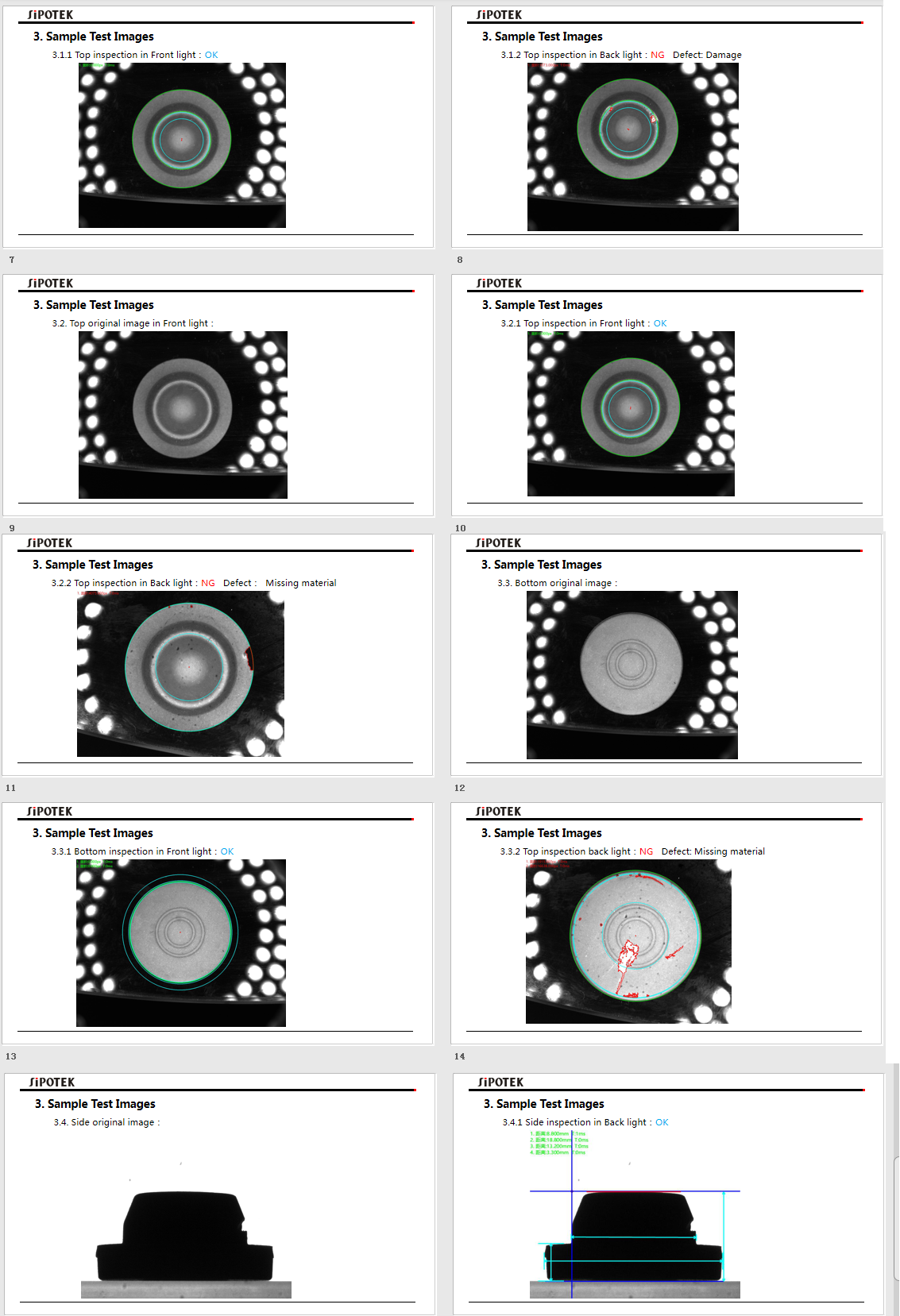

Rubber closures are an essential packaging for parenteral drug products, and they can be a source of particulate matter. The machine vision systems can provide imaging-based automatic inspection and process the image data in applications of automatic inspection and process control. Cameras are used to capture the image data from the examined closure. We didn’t say 100% vision inspection can detect visible defects but 99.99% is available. The defects are some flaws, damages, scratch, missing-injected, burr, deformation and other colors.

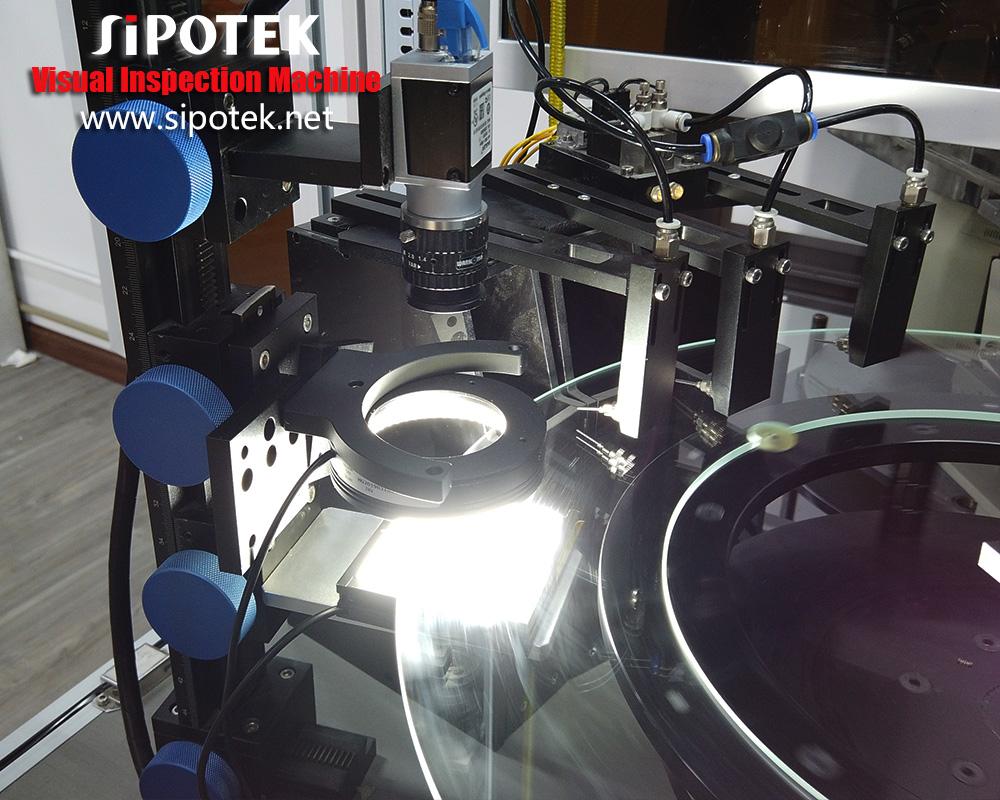

Sipotek have developed its machine vision techniques for over 16 years since 2002. Our automatic optical vision inspecting system is designed to inspection a variety of products ranging from electronic, plastic, rubber, magnetic metal industry. In pharmaceutical filed, the vial plungers are inspected strictly with an modular vision system. During inspection process, the system continuously conveys the plungers through a glass plate, undergo through the endoscope cameras after which the products are either accepted or rejected.

The inspection process are not obscure to understand.

Prepare your rubber stoppers / rubber plungers in the container. The operator pours the parts into the vibration bowl feeder. If you want to have an automatic feeding, a hopper is a good idea. The parts are oriented from a hopper into the vibratory bowl feeder, out onto an accumulation track.

A glass plate, the rotating mechanism whee,l presents the products for the vision section. They will stand in order one by one, ready for image-capture and quality-check. Here the top and steep side and bottom are inspected for defects and the total height, diameter are measured.

A special mechanism with an ejector blows failed components off the glass plate and into the rejection bin. Parts that have been accepted continue to be transported another OK bin, thus separating bad ones from the good ones.

An intelligent product tracking system supports counting ability and the correct allocation of the parts into 2 separate station: accept and reject. This results in very low levels of false rejects and false accepts.

The automation visual inspection in quality control is not a brand new idea around the world but last long years. What we can do is focusing on improving the performance of the process, assisting in reducing costs of defects with a higher and safer condition. Sipotek will keep further supports industry leader in these pharmaceutical manufacturing fields by minimizing the risk of component related issues in drug fill-finish operations.

Sipotek provides such a visual system to guarantee effectively and accurately quality control. The operation system is user-friendly designed. The structure is compact and space-saving. By separating the negative parts, the final products are totally in good state.

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/