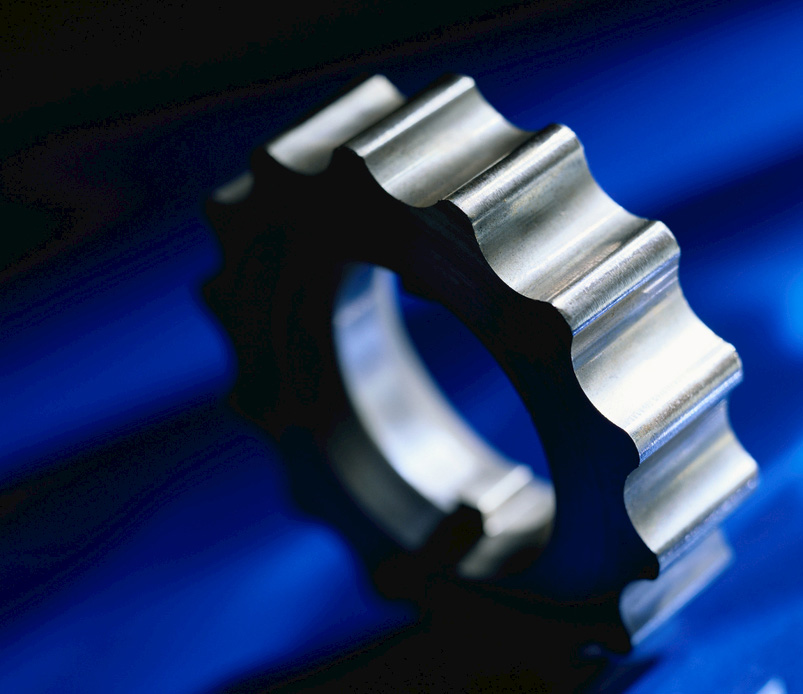

Permanent magnet ferrite magnets are widely used in automotive, home appliances, consumer electronics, computers, communications products and other end consumer products, and are an important part of these products – the components of the motor. For example, a fuel pump motor of an automobile, a compressor motor of an air conditioner, a drive motor of a computer, a power motor of a power tool, all are used as a rotor or a stator.

In recent years, with the rapid development of China’s automobile industry and electronics industry, the demand for permanent magnet ferrite magnets has also increased significantly.

During the production and processing of magnetic tiles, due to factors such as raw materials, processes, equipment conditions, and human factors, the surface of the magnetic tile will have some defects, such as cracks (including deep cracks and shallow cracks), collapse, under-grinding, and indentation. These defects have a large impact on the performance of the magnetic tile, which is related to the stability, safety and reliability of the electric system. At present, the production of magnetic tiles is basically based on manual visual inspection. This detection method is inefficient, workers are labor intensive, it is easy to cause missed detection and misdetection due to fatigue, which is difficult to ensure the quality of products.

Magnetic material machine vision technology is more and more widely used in product defect detection. Machine vision technology can automatically, quickly and efficiently surface defects inspection of products and greatly improve production efficiency. The machine vision system uses LED as the light source, mixed illumination mode in bright and dark areas, and uses high-precision and high-resolution industrial cameras to shoot, analyze and process surface image information through computer to identify and classify defects and measure all key parts size or area.

For more information, vision our home page on www.sipotek.net

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/