Description

Best price of Sipotek Aoi system machine for screws quality problem check

screws with cross, triple or special head, phone assembly screw, etc.

Product Parameters | |

Machine Type | High speed Inspection Machine (Glass plate) |

Application Field | For parts can lie stable such as screws, nuts, lathe parts, stamping parts, injecting model, cooling elements and fasteners. |

Turntable | Dedicated round glass turntable |

Optical System | Germany high magnification CCD industrial camera, Japanese lens, professional light source system |

Camera Quantity | Standard with 3 ( 1-8 optional) |

Operate System | Germany Siemens Industrial Computer |

Video Inspection Software | Sipotek Machine Vision Inspection System |

Feeding System | Dedicated feeding guide line, vibration feeder x 1 SET, automatic feeding and container devices (optional) |

Package System | Automatic counter and package machine (optional) |

Inspection Speed | 300-1200 pcs/min accoring to samples size, shape, etc. |

Accuracy | Highest level up to±0.01mm |

Inspection Details | Appearance inspection: outer side, inner side, opposite side, diagonal, length, height, concentric, roundness, step size of each part, angle, sharpness and etc |

Defective inspection: 360 degrees teeth, rotten tooth, bad tooth, oblique tooth, threading, inside burr, missing material,Internal hole blockage, cracking, glitch, solder joint area,Imprint, with or without internal teeth, inspect all functions of screw with flat head | |

Power and Voltage | Two phase 220v, 50Hz |

Rated Power | 1KW |

Air Pressure | Not lower than 0.35-0.7MPa |

Weight | Around 500kg |

Working Temperature | -3℃~45℃ |

Storage Temperature | -20℃~60℃ |

Machine Dimension | 1000mm (Length) X 1000mm (Width) X 1800mm (Height) |

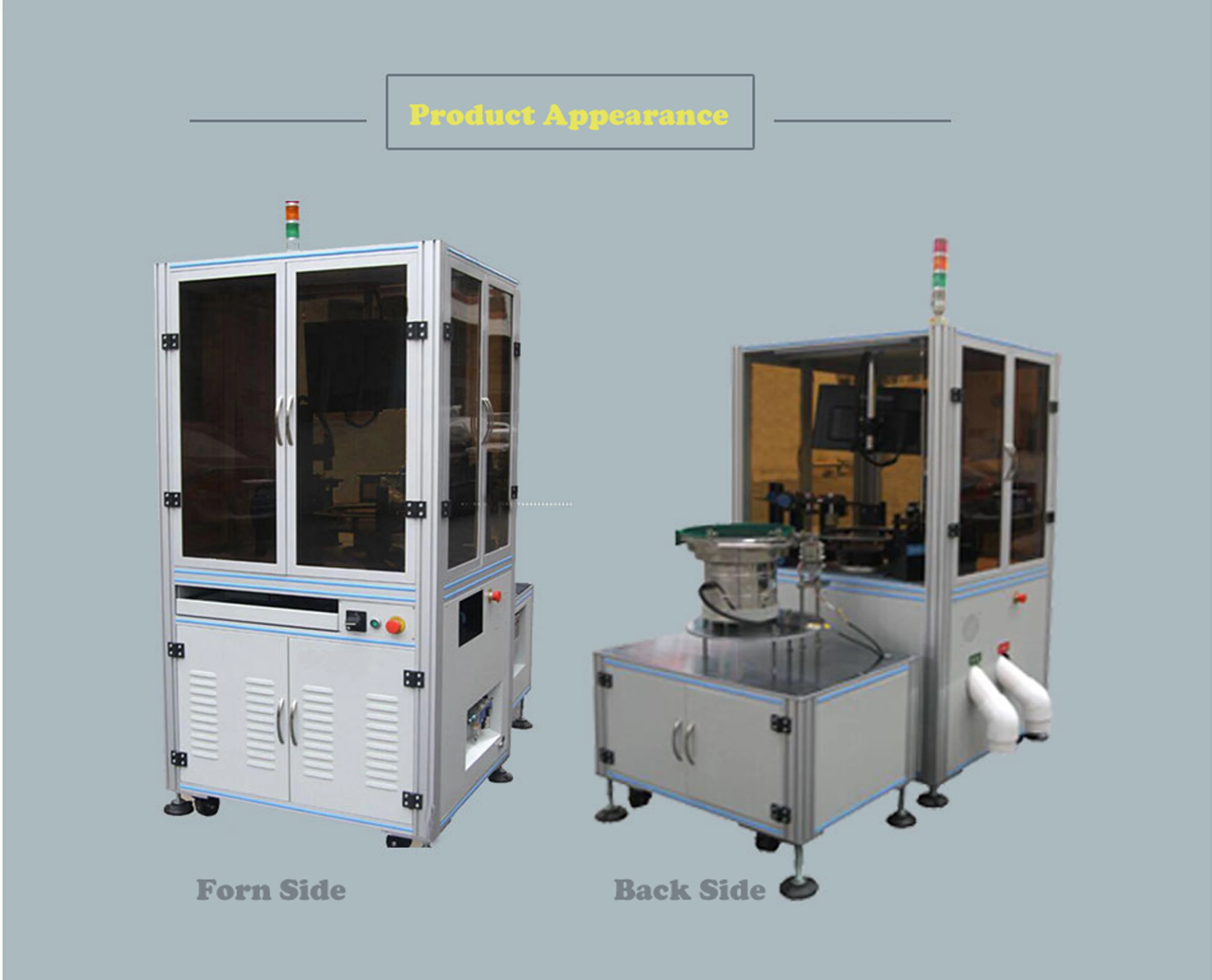

1. Model type: T300

2. Machine characteristics: special vibration disc automatic feeding mechanism

3. Main functions: inspection of length, height, diameter, mixing, deformation, missing material, burr, black spot, scratch, etc.

4. Trial scope: suitable for testing rubber ring, screw, mobile phone accessories, stainless steel, aluminum, plastic and other devices

5. Detection accuracy: the highest accuracy can be up to 1mu

6. Detection efficiency: The highest detection speed can reach 1200 branches per minute.

Here are some inspection images of screws, inspecting under special lighting source images were capture by ccd industrial cameras with FA HD lens.

Product details

Free Machine training

1 year warranty guarantee

Life time technical support

Shenzhen Sipotek Technology Co., Ltd

Since its establishment 15 years ago, Shenzhen Sipotek Technology Co., Ltd. has been committed to the research, development and manufacturing of image technology and machine vision, with more than 70 senior R&D personnel of machine vision system and industrial automation engineers. The company’s key technical personnel are mainly from huawei, byd, foxconn and other first-class manufacturing enterprises, with many years of mature experience in software design, visual and image comparison technology, industrial automation and other aspects.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: +86-18617182707

Website: http://www.sipotek.net

1. What’s the minimum order quantity(MOQ)?

– 1 machine, small batch and large volumes are acceptable.

2. When can I get the quotation?

– We usually respond within 24 hours on working days receiving your quotation. Then we will discuss the inspection details and requirements as much as possible to design your inspection solutions. After receiving samples for testing and evaluating, a solution will be born and will be forwarded to you with quotation within one week.

3. Which is the safe payment method to trade?

– We accept T/T, LC, Paypal, Trade Assurance and Secure payment on Alibaba platform.

4. How long will it take to produce the machine?

– For standard machine, it will be 15 days for manufacturing.

– For non-standard machine, it will be negotiated customized according to your requirements.

5. What’s the shipping method of Sipotek?

– We are able to ship worldwide where Ocean shipping or Air shipping can reach.

– Machines will be packed safely and protectively to ensure you will receive a brand new one.

6. How do you ensure quality control?

– Sipotek is a professional machine vision inspection supplier with 16 years experience of research and develop in this field. We ensure 100% brand new machine production. Our machine is stable and reliable to help you increase quality efficiency.

7. What’s the warranty and after-sales service?

– Sipotek warrants all the machines made by Sipotek under normal use of a period of A YEAR after the date of the original purchased. Sipotek will train buyers how to install the machine and how to use the machine for free. We also provide a life-time technical support or software upgrade service.