Sipotek is a professional china automated optical inspection machine manufacturers located in shenzhen city,major products including visual inspection machine and automated optical inspection (AOI) machine.

Today we will talkding about the the basics of automatic optical inspection (AOI) machine,system or equipments

AOI, Automated optical inspection systems makes use of visual methods to check circuit board defects. They have the ability to detect various defects in surface characteristics such as scratches, nodules, and stains, and also the most well-known dimensional defects such as short circuits, open circuits, and thinning of the weld. They can also detect missing components, incorrect components, and wrongly inserted components. As such, they have the ability to perform all visual checks performed in the past by manual operators and much more quickly and accurately.

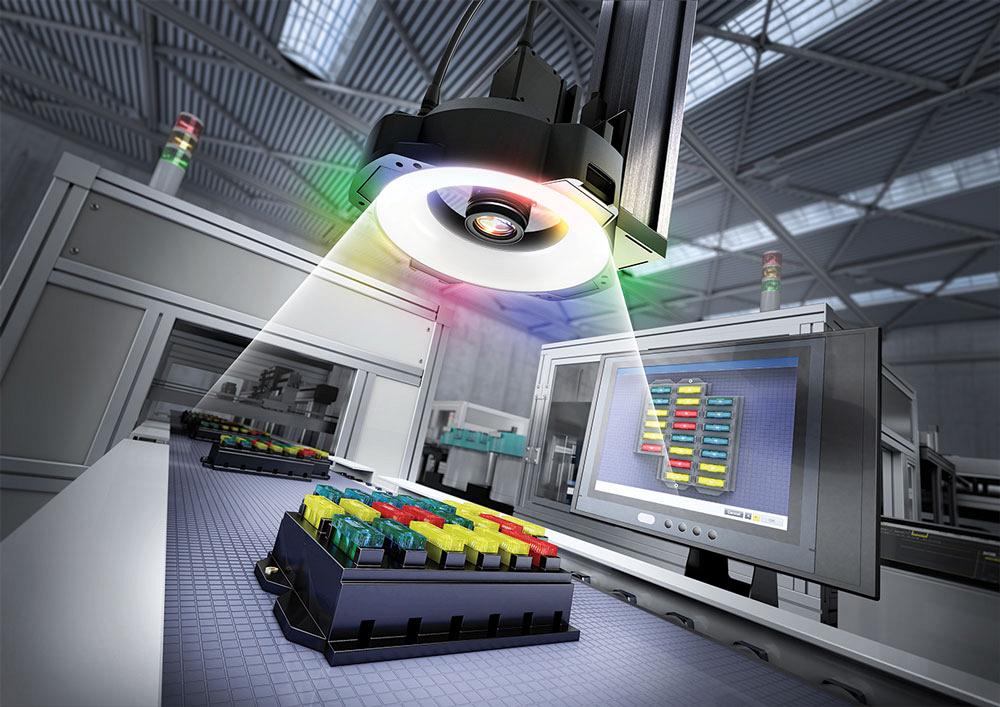

They do this by visually examining the surface of the panel. The circuit board is lit by different light sources and one or several high definition cameras are utilized. This way, the AOI machine can be able to develop an image of the circuit board

The Automated optical inspection system AOI uses the acquired image that is processed and then compared to the knowledge of the machine on the proper operation of the circuit board. Using this comparison method, the AOI system can now detect and expose defects or suspicious areas.

AOI makes use of a variety of techniques to provide satisfactory circuit board analysis or any defect:

Template Matching: With this form of AOI process, the automated optical control system compares the resulting image to the image of a “golden board”.

Pattern Matching: By using this technique, the AOI system stores information from good and bad printed circuit assemblies, while matching the resulting image with them.

Statistical matching: Now, this approach is quite similar to that described earlier, except that it uses a method based on statistics for the treatment of problems. It stores the results of different boards and different types of errors, to be able to tolerate acceptable minor deviations without reporting failures.

In order to form the database of what an ideal board should be, PCB design information and known status board are used as described below.

Thanks to improved technology, AOI systems have been able to accurately predict faults and have a limited number of seamless scenarios. Hence, these AOI systems are a very useful element in sophisticated production environment.

AOI image analysis and capture

The automated optical control system is one of the important elements of an AOI system. This captures an image of the circuit board assembly of the printed circuit board which is later analyzed by the software for processing in the AOI system. There are many variations of the image acquisition system which depend on the exact application and cost/complexity of the AOI system.

Imaging systems can include a single camera or multiple cameras to provide better images and the possibility of 3D functionality. Cameras must also be able to move under the control of softwares. This will allow them to position themselves optimally for a given assembly of circuit boards.

In addition, the type of camera has a huge impact on performance. Speed vs. precision is striking balance and will have a lot of impact on the type of camera used.

To learn how a visual inspection machine can automate the production process, one can visit the website http://www.sipotek.net/ .

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/industries/