Rubber seals, silicone seals, inflatable and insert seals, extruded rubber profiles, are common silicone or rubber products and always made by massive production process. The quality are of greater importance and it’s not an easy task for human quality inspector. Factory automation is greatly applied in many manufacturing industries. Manufacturers are cater to guarantee a higher percentage of qualified items by applying automation facilities on quality control. The visual rubber stopper inspection machine is quite helpful.

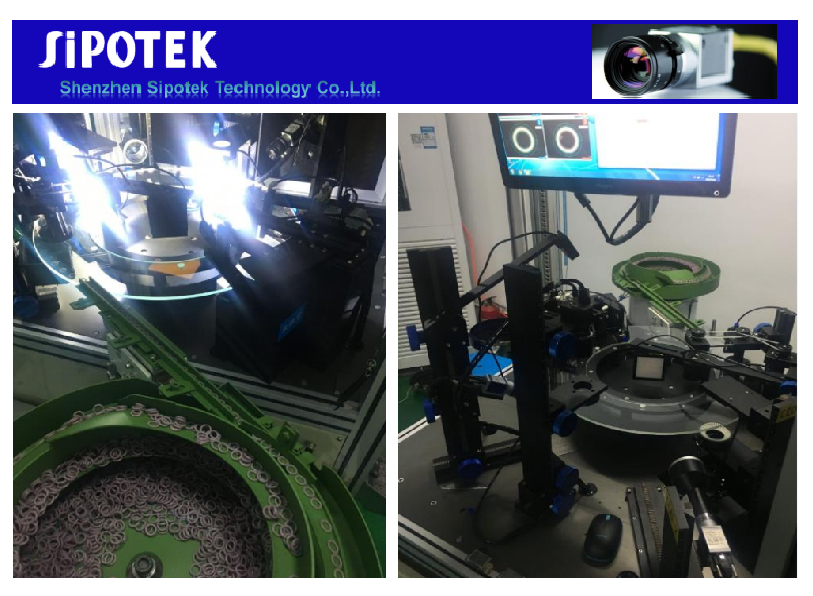

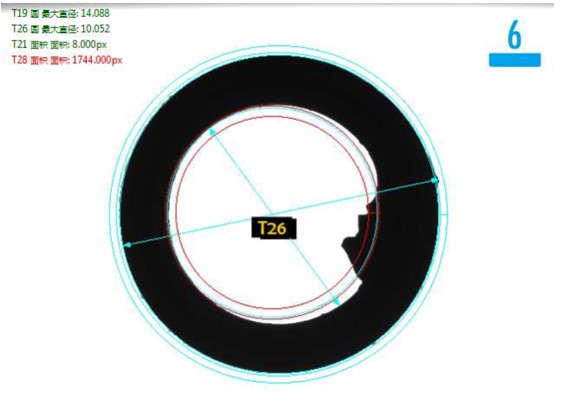

Inspection requirement are the first information we need to collect when we produce a new inspection system. The systems are similar but mostly customized. So we need to confirm several aspects such as how to feed, how to reject NG, and how many sides are inspected, etc. So the discussion will be necessary on pre-production step. On next step, Sipotek vision engineer or mechanical engineer need to do a lighting test. They will place the sample on the glass rotary plate under special lighting source either from front illumination or back illumination. A camera with enough pixels will be set on special location where it can capture the sample image as clear as it could because all inspection task should rely on clear images. The engineer will set the parameters for the visual system and it will automatically recognize the defects.

What kind of defects will a rubber stopper has? On dimensional aspect, the total height, head diameter; On surface aspect, the molded defects, bubbles, eccentricity, shape faults, burrs etc.

What will the rubber stopper visual inspection machine has? The feeding, the inspection and sorting mechanisms.

Feeding mechanism

Vibration bowl feeder is a good choice for rubber stoppers. The operator can load the bulk intto the bowl. It will automatically turn and carry the rubber stoppers until they can be kept in a straight line.

Inspection mechanism

From the vibration bowl feeder, the rubber stoppers will be transported through a linear chute to the glass rotary plate. The glass is transparent and it can provide the bottom inspection for the products lying on. The inspection is executed by means of a high-resolution camera such as 5million pixel with an accuracy of 0.01mm. Top, bottom and side surface will be inspected as well as the geometric dimensions.

Sorting mechanism

The rejection stations are set aside with the glass plate where all the inspection station is finished the task. Sorting will happen after all inspection finished. The rubber stoppers will finally and quickly inspected as NG or OK. The NG will be rejected to NG bin while OK will be transported to OK bin. So the sorting is done.

About us

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of smart machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-186-1718-2707

Email: [email protected]

Website: http://www.sipotek.net/machines/