Machine vision is the techonology related to CCD cameras, lens, lighting, plc, sensors, feeders, rejectors, etc. The vision inspection software system is the key to guide these tools and let them take actions during inspection process. Vision inspection system manufacturers will either develop their own software system, or purchase from a third-party company. With a professional team of 70 machine vision engineers, Sipotek develops its own vision inspection system on machine vision size measurement software copyright. Currently, the software can support multiple tools for different inspection tasks.

- Circle dimension measurement (Inner and outside diameters and balance, thickness);

- Line to line distance (Suitable to measureregular rectangles in the length, height, width, step and step width);

- Dot to dot distance (Suitable to measure bur size, dot to dot size);

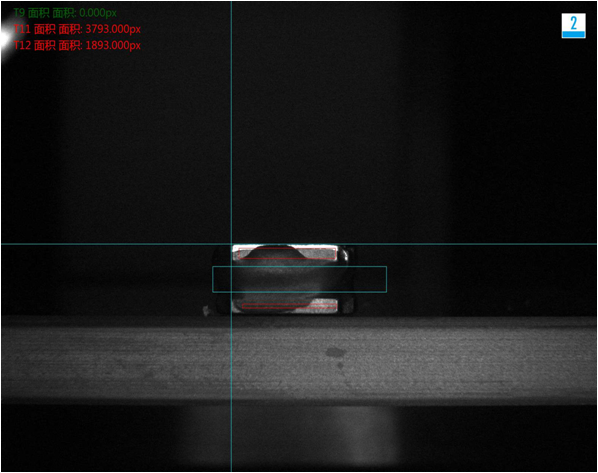

- Areameasurement (Suitable to measure specific area of parts,decide good or not);

- Screw detection (Suitable to measure external diameter, oblique thread, teeth quantity and distance);

- Positioning (Suitable to detect relative position relationships of parts);

- Defective inspection (Suitable for surface defects, scratches and trace);

- Compare function (Set the template based on good part to match quality of the inspected parts):

- OCR recognition (Suitable for different character recognition);

- Angle measurement (Suitable for appropriate angle between edges);

- Template matching (Suitable to use the established template to search the same part of the images and output the number and position);

- Inner and outer edges detection (Distinguish inner and outer edges of the parts);

- Block positioning (Position fixed section and measure the dimensions):

- Functions combination (Above mentioned functions can be combined to achieve multiple inspection and measurement task).

All details above are the functions of our optical sorting machine. Some functions can be achieved by using the above mentioned software system. Including dimensional measurement (Circle inner and outer diameter, regular circle length/width, step height, step width), screw inner and outer dimension measurement, gearwheel/gear head/circle thread/root measurement, burrs inspection, surface dust, product completion detection (edge broken, part missing), surface scratches detection, character recognition, character inspection and etc.

Through our inspection software system with combination of these functions, our optical segregation machine can achieve more functions on images-processing, inspection, measurement and recognition.

Established in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: +86-18617182707

Email: [email protected]

Mobile Phone + 86 18666216027

Email : [email protected]

Website: http://www.sipotek.net/

Website: https://www.topvision.net