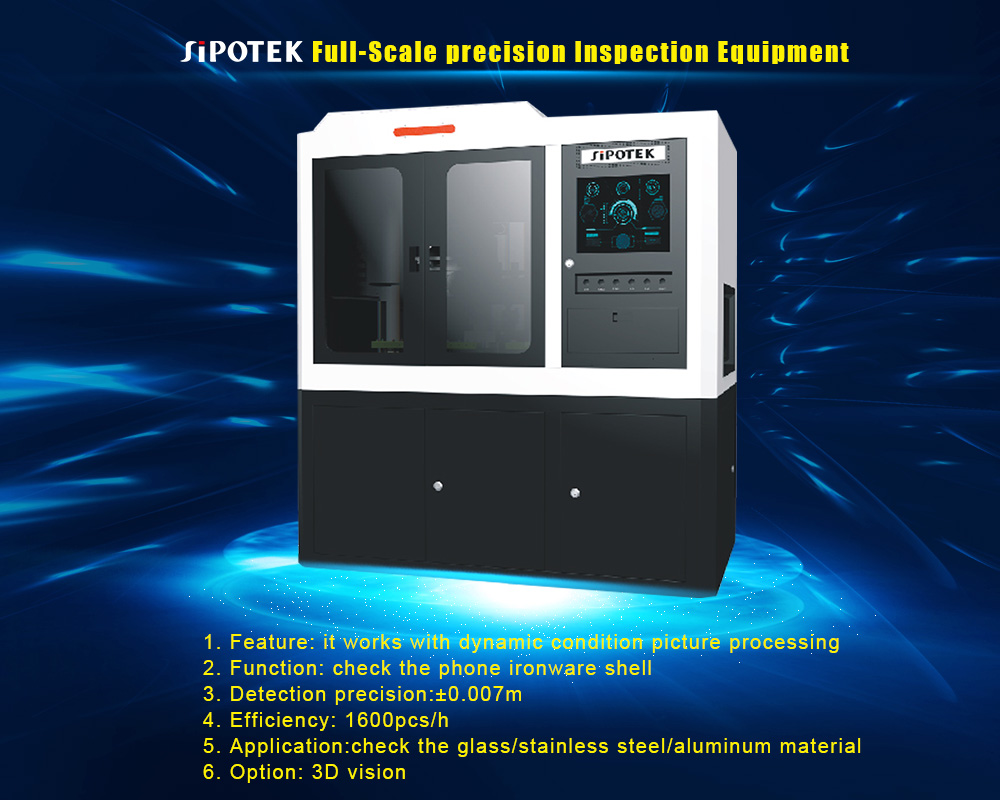

Shenzhen Sipotek Technology Co., Ltd. is a professional automatic visual inspection machine ,automated vision inspection system,industrial machine vision camera,automated optical inspection machine ,optical sorting machine manufacturer from china with low cost and high quality.

Sipotek automated vision inspection systems are turnkey solutions for total confidence of supply. Sp-KS05 Glass Disc Vision Inspection. The Sipotek glass disc vision machine is developed specifically for 360° quality inspection. Vision Inspection & Quality Control and Vision System Integration.

Today we will talking about what are atutomatic visual inspection systems capable of?

Sipotek Visual Inspection Machine 10

What are visual inspection systems?

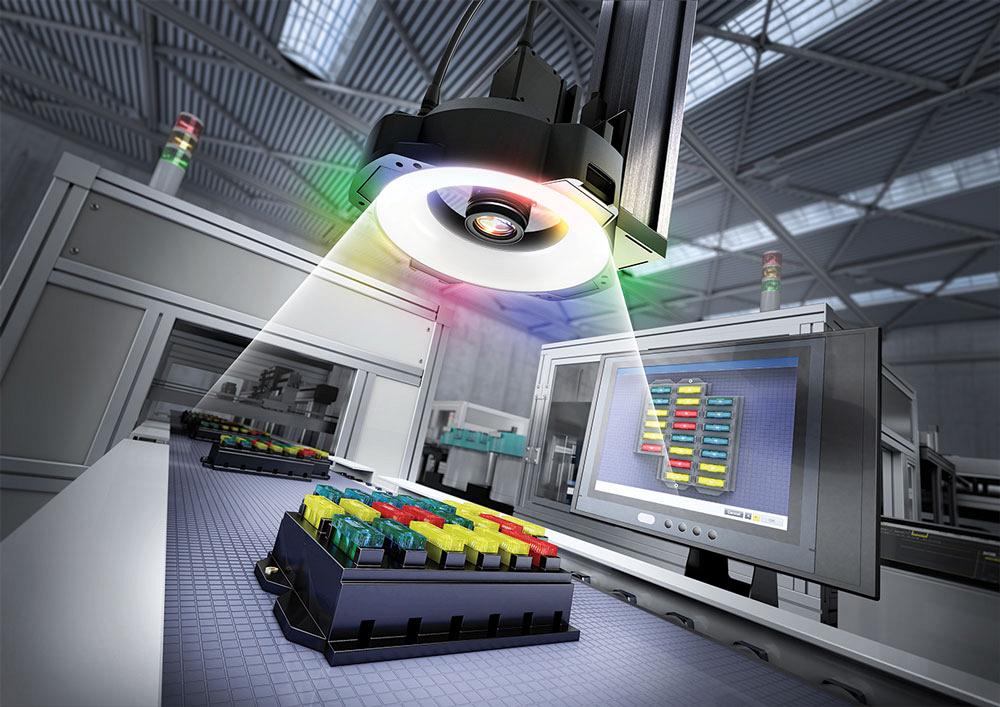

One can define visual inspection systems as machines that offer automated image-based inspection for your own convenience for a wide variety of manufacturing, as well as industrial applications. Although this has not emerged as a new technology, 3D, as well as 2D vision systems, can also detect problems for the purpose of automated inspection, quality control, robot guidance, as well as for classification, along with many more.

What are visual inspection systems?

There is no doubt that these inspection systems are on par, and an intelligence that is unparalleled with the other alternatives present in the market. They also come with a camera or, in some cases, several cameras, even with lighting and video. These visual systems have the ability to measure parts, as well as verify the parts to verify whether they are in the correct position or not, another purpose of the system is to identify the shapes of the parts. They are also able to classify, as well as measure parts at incredibly high speeds. With the help of a computer software, one can process the images that have been captured while the process is taking place and one is trying to obtain the measure to capture the data. These systems are intelligent enough to be able to make decisions that, later, will affect the function that one is trying to guess, this is often done in a failure / approval capacity for an operator to act. These types of inspection systems can also be integrated into one’s lines to provide an invariable supply of information.

Applications of visual inspection systems

These systems are being implemented in a wide range of industries that need to have a quality control as a requirement for their products. Take, for example, that these visual inspection systems can assist in robotic systems in order to find out the positions of the parts so that they can be optimized and automated during the manufacturing process. The data that has been associated with the help of a visual system can be applied even more in various required fields so that one can improve efficiency in the packaging, sorting and manufacturing process. In addition to this, the information can be stored by the visual system so that one can identify problems in the manufacturing line or any other function being tested in order to improve efficiency, and stop a process that hinders it in any way , and recognize products that are unacceptable. Therefore, visual inspection systems have a variety of applications that can control various locations regardless of their field of study and domain, it is also a necessity and a necessity for some of the industries that control quality as well as the order in business management.

Current industries where you use visual inspection systems

There are several industries where this verification method is currently beginning to be used to avoid potential errors. Some of them are obvious: In the industry of spare parts and welds its continuous use is needed to avoid manufacturing errors of both vehicles and buildings.

However, the medical industry also uses these systems to avoid damage to the quantity of medicines in their containers and the food industry to verify the quality of food.

The truth is that this system is increasingly being integrated into the world of mass production.

For more about visual inspection systems,you can pay a visit to sipotek at http://www.sipotek.net/machines/

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

Sipotek Visual Inspection Machine

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-+86 18666216027

Email: [email protected]

Website: http://www.sipotek.net