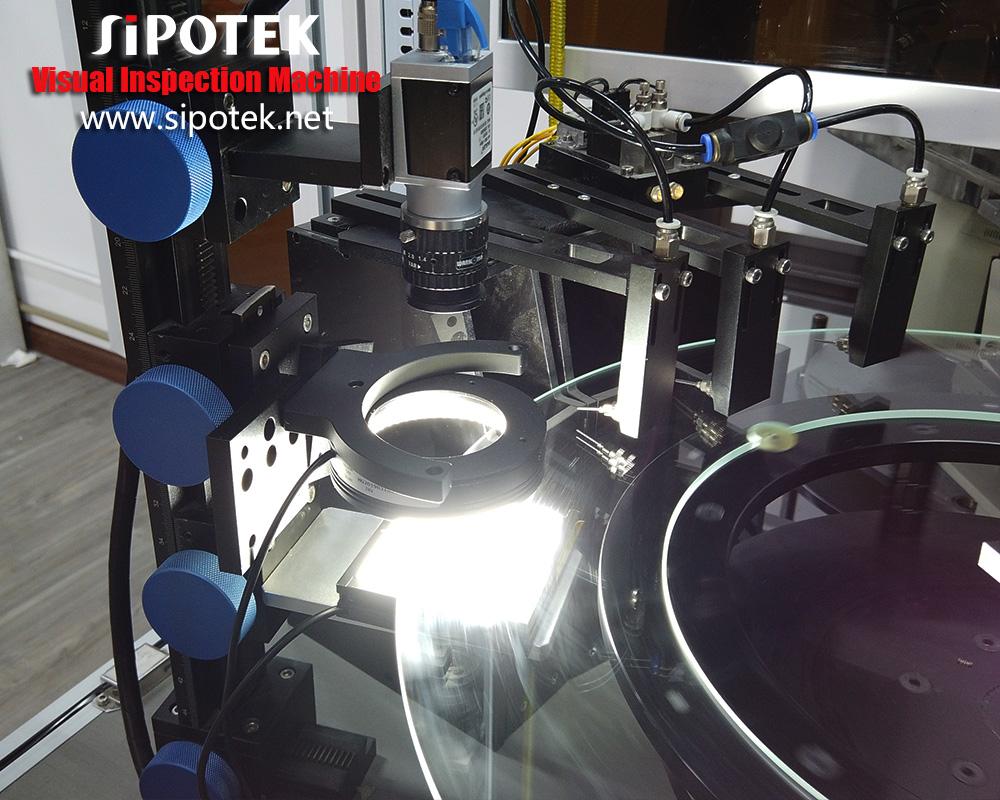

Shenzhen Sipotek Technology Co., Ltd. is a professional automatic visual inspection machine ,automated vision inspection system,industrial machine vision camera,automated optical inspection machine ,optical sorting machine manufacturer from china with low cost and high quality.

Automated optical sorting can be used to separate different grades of glass, paper, plastic and aseptic (Tetrapak) containers from a waste stream or from each other using a variety of sensing methods.

Sipotek offers a line of automatic optical sorting machine that can also be used to do automatic sorting. The optical sorting machine product line offers users flexibility over a wide range of parameters that can be measured as well as sorting machines that are designed specifically for certain objects such as screws, rivets or bolts. One sorting system from the optical sorting machine product line is designed to discriminate metallic objects based on hardness. Each optical sorting machine offers powerful technology to any production line.

Today we will talking about what is the most important function that optical sorting machine manufacturers must fulfill?

Sipotek Visual Inspection Machine 8

Product inspections were a bit invasive, and this method had to change.

Previously, when it came to performing some inspections for products, previously they had to be tested through methods considered as invasive, and these would not be able to ensure that the rest of the products that were mass produced had exact characteristics between them .

The effectiveness of invasive inspections did not ensure that all products

But this method was not at all effective, since many manufacturers compromised all their production, and in some industries, a non-invasive method was undoubtedly the best solution to successfully carry out all their inspections.

Thanks to the birth of visual inspection machines, non-invasive methods gained strength.

This is how ideas began to emerge on how to perform non-invasive inspections, so the visual inspection machine was born, and along with them the optical sorting machine manufacturers, who perfected the processes to which these machines were dedicated.

The optical sorting machine manufacturers were responsible for incorporating some more functions to achieve a perfect organization of all the elements of production. Through a visual inspection machine they can correctly classify all the elements that are approved to go on the market.

The evolution of technologies

The technology implemented by the optical sorting machine manufacturers has been advancing rapidly, so much so that at present they have more than one specialized version to manage to classify some elements as grains, and even pills.

Many industries have used these review processes to offer the best products to all their consumers and because they are such a necessary resource for many companies, optical sorting machine manufacturers have a great responsibility, to create the most precise machines, whose margin of error is virtually imperceptible.

Manufacturers have faced the task of incorporating new revision methods.

So the functions of these manufacturers have been progressively evolving, so much so that a form of classification based on the color of the objects has even been developed. Harvested foods include this type of review within their procedures. This way you can get all the right foods packed and sent to the distribution sites.

Thanks to all who perfected these techniques, we can receive the best quality products and foods in our homes. For example, during the processing of food that has been harvested, there is a risk of having the presence of other elements outside of which it is being packed, and the safest way to avoid this is through a visual inspection, where they will rate the correct items.

But, the method of choosing objects that are within the correct parameters is based on different principles, for example in comparison. That is to say, that the information about the most common errors is incorporated into the system, such as the elements that are easily mixed with the products, and upon receiving a match, they immediately discard what does not correspond to that selection. Achieving stay with what had initially been determined as correct.

For more about optical sorting machine,you can pay a visit to sipotek at http://www.sipotek.net/machines/

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

Sipotek Visual Inspection Machine

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: +86 18666216027

Email: [email protected]

Website: http://www.sipotek.net