Machine vision system for product external defects inspection solution is always a difficult point for visual case. This article is to introduce the design of machine visual appearance defects inspection system development process and key point.

Key point of defects system design

Most PC-base visual inspection system can perform inspection mission. When we design the defects inspection system, it is necessary to confirm what inspection task should be accomplished and what performance specification does this task requires. For example, mostly visual system will be used to find the defective components in the electronic production process. Can the visual system with a camera see the defects? Answer this question often need to built a unqualified and qualified testing database, then built a sample system which use this image database in the above base. The advantages of this method is that only need a little modify can get the correct software setting.

Illumination system selection

Illumination is very important in visual inspection application, because it can sure the image acquisition can be carried out in consistent conditions. The illumination should be correctly used so that the components under the test from a sharp contrast with the surrounding background and receive as many gray degree as possible so that the visual effect can be performed obviously. For the high speed movement components can use the flash light source to fix the image in instant.

The influence of nature light outside

The other purpose of illumination is to reduce the reflection. Sometime, reflection comes from the surrounding light which can change by time, therefore, the day and night light will be change much in same occasion which need to configuration illumination or use a light cap to block out the surrounding light.

Hardware considerations

The first thing for choosing visual system is to choose the correct cameras and lens. The base unit to built image is called pixel,a common image actually is thousand and million pixel filling the frame. The specific application requirement is not only the pixel of each image, but also the style of camera lens.

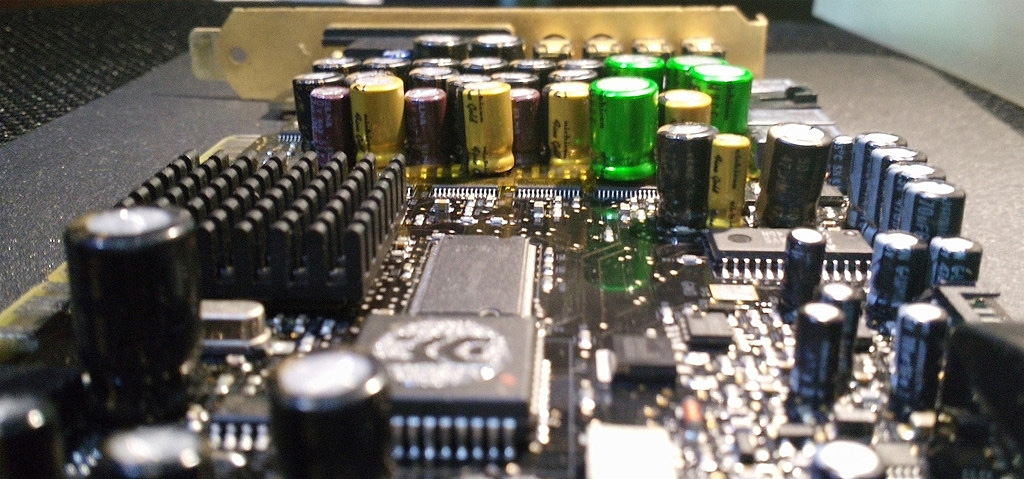

The influence of camera colors

The other one is to decided whether to use color or monochrome. Although color camera can produce more attracted image, color can not add more value information, in common situation it will need more time to process(monochrome image usually is 8-bit/pixel, color image need 32-bit/pixel), this point in measure edge distance application will be more outstanding. But sometimes color is the only identified feature, in this time color will become very important, for example, when inspect the fuse wire, capacitance or resistance may need search some specific colors. For the high resolution color application situation, three pieces style pr RGB camera can be considered.

When choose a visual system base on PC, it also need image acquisition hardware, in this time the feature we need to consider includes driver software and hardware whether they can integration well with motion control and data acquisition. For example, component conveyor speed can be monitored by motion control so that image acquisition is synchronization with the whole process. Machine vibration,pressure monitor and temperature control include in the production system so that to draw up maintain plan in advance. Users can easily integrate the belt control and image acquisition hardware to achieve synchronization between data acquisition hardware, software and motion control, and obtain a complete solution.

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/