Automated rubber stopper inspection machine is a custom built equipment used for rubber stopper quality control. Normally, we choose offline vision inspection mechanism for this kind of rubber products. A rubber stopper is a small, tapered plug used to seal the openings of test tubes, flasks and other laboratory glassware. Stoppers made of cork are also available for this purpose.

Let’s introduce how we make a customized built machine for our clients.

First of all, send us your inspection requirements as many as possible, telling us what’s the size of the rubber stoppers, what’s the surface defects you want the machine to detect. Our engineer will have a first evaluation about your requirements and then will decide whether we can continue the project.

Secondly, when the project is feasible to do. We will ask customer to prepare samples both OK and NG 10 pieces for each type of features for each models. Customer will help to label the NG samples telling which kind of defects they are. After receiving the samples, our engineer will arrange a lighting test.

Sipotek Visual Inspection Machine 38

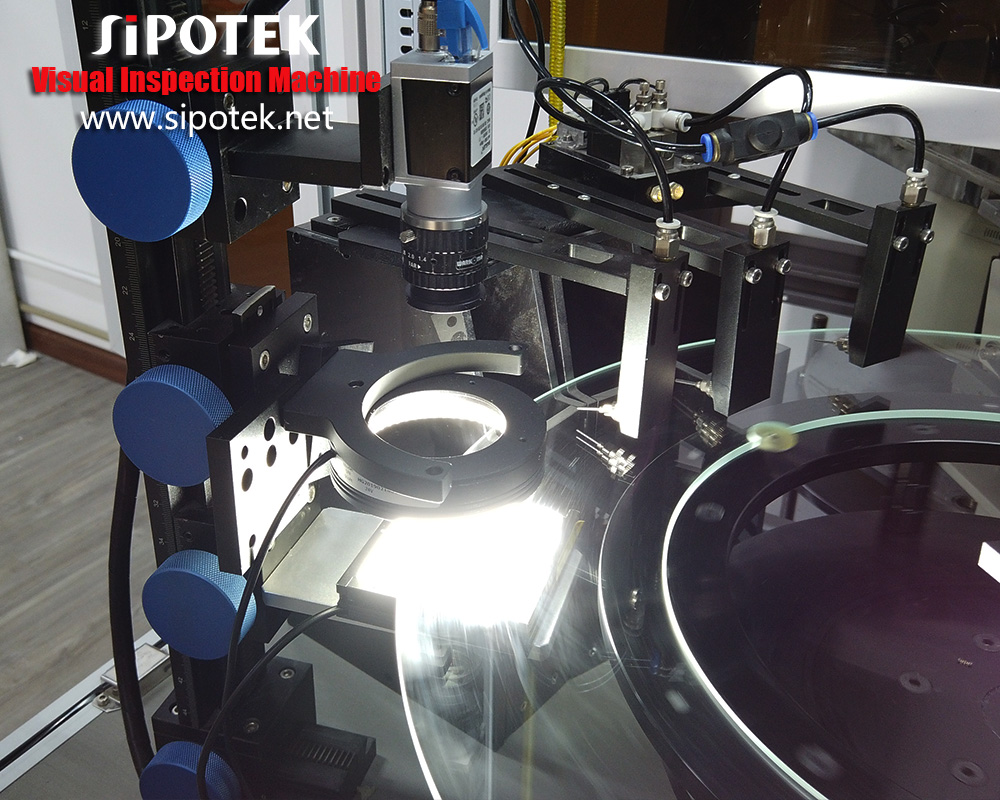

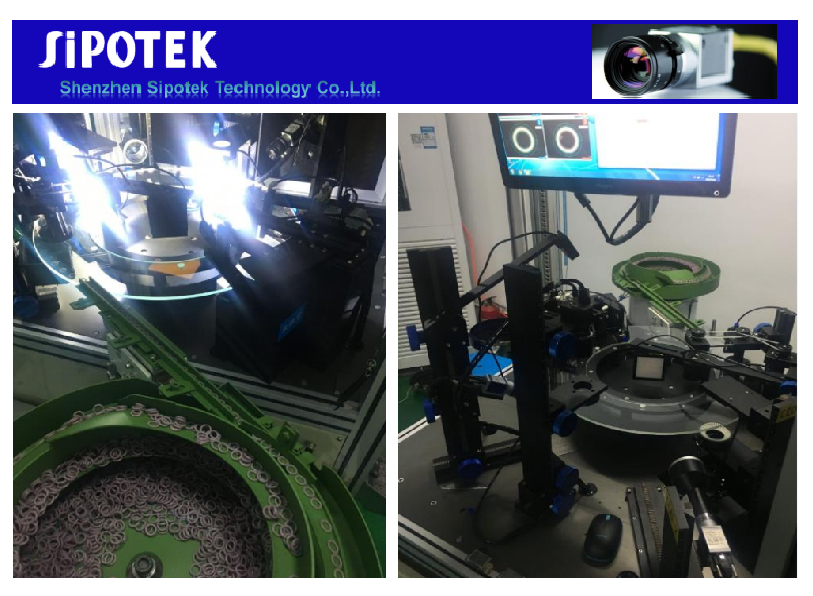

Our visual inspection machine/automated optical inspection (Aoi) are using image-based systems. Only under enough lighting background, should the images be captured clearly.

So our engineer will place the sample on a transparent glass plate, with front lighting or back lighting conditions, adjust the CCD cameras that work with the lens and use it to capture the images. The system can be programmed to recognize the defects or dimensions with respect to the Ok sample parameters and determine the images as Ok or NG and show on screen.

Thirdly, our engineer will conclude the testing into a solution report which then will be sent to our customers. The solution report will contain generally four parts.

Part one inspection requirements and feedback

Part two machine configurations

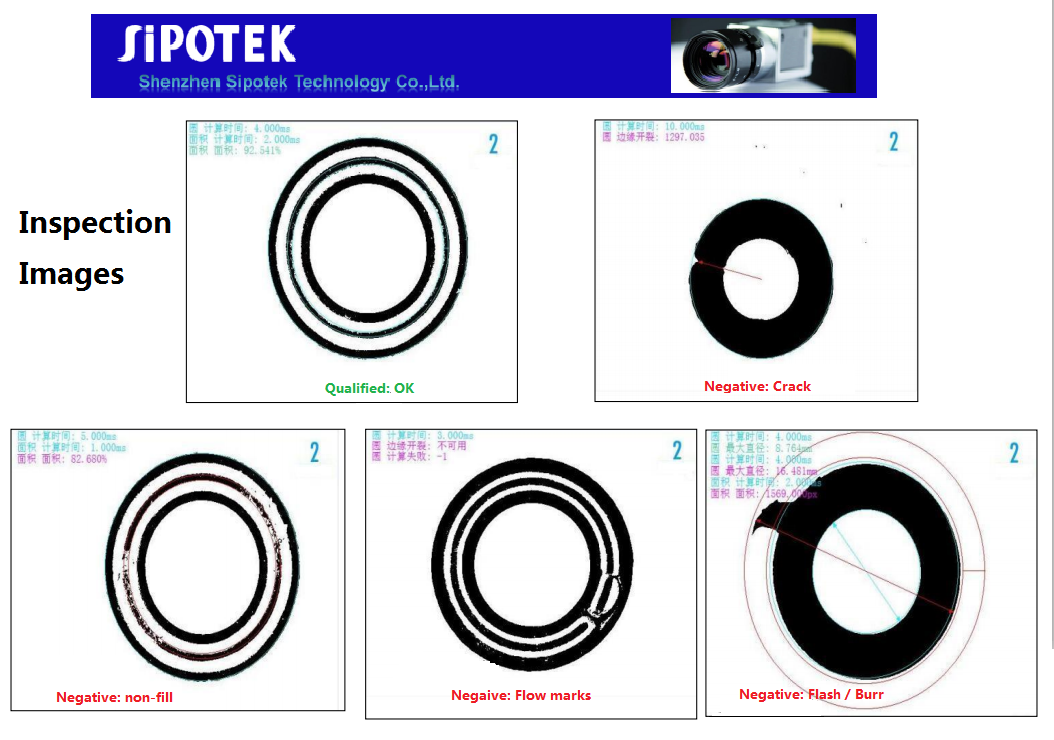

Part three testing images

Part four machine installation information

The images can show to customer when the system recognize dimensional or surface problems, it will define as NG. If the system can not find the problems, they are unable to detect, and we will also report to our customer. So the lighting test is very important to evaluate if we have the ability to do the case and serve our customers.

Fourth, if the solution report is accepted and able to solve customer’s problems. We will discuss about the order details. The machines are mostly with customized systems according to products. If there is a chance that we have a same system for the products, we can neglect the testing step. The customer only need to send samples to run the machine and see the speed and result.

About US

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-186-1718-2707

Email: [email protected]

Website: http://www.sipotek.net/machines/