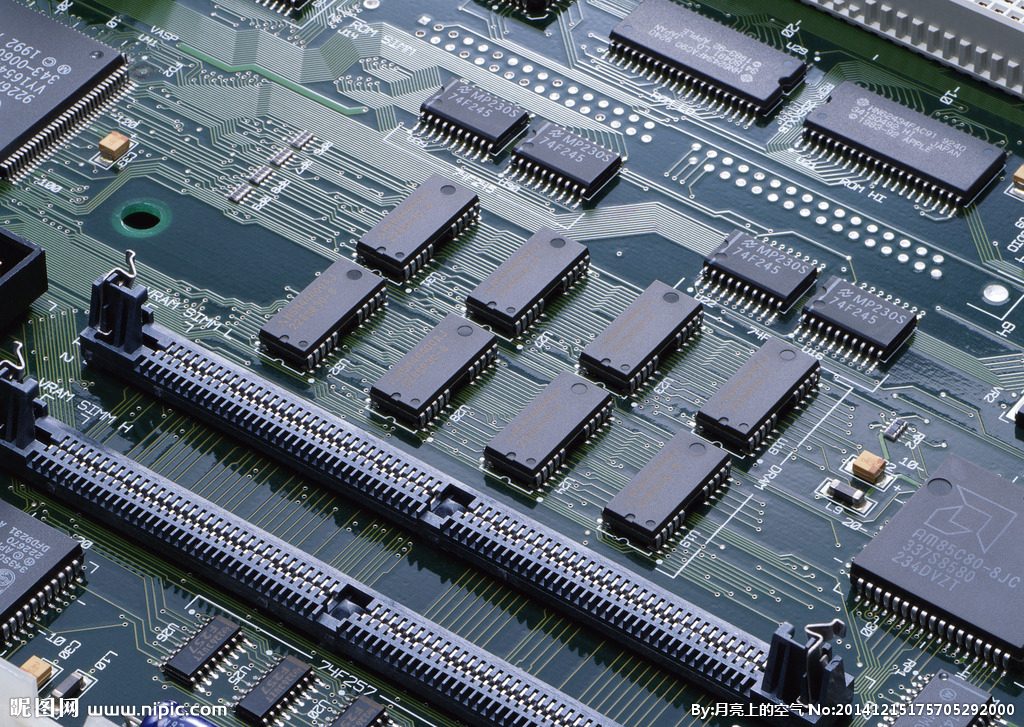

As it is said from the Wikipedia, the automate optical inspection also called as AOI, is an automated visual inspection for PCB, LCD, transistor manufacturers where a camera autonomously scans the manufacturing process because it is a non-contact test method. It is implemented at many stages through the manufacturing process including bare board inspection, solder paste inspection (SPI), pre-reflow and post-reflow as well as other stages. Historically, the primary place for AOI systems has been after solder reflow or post-production. Mainly because, post-reflow AOI systems can inspect for most types of defects at one place in the line with one single system such as component placement, solder shots, missing solder,etc. In this way the faulty boards are reworked and the other boards are sent to the next process stage.

With the demand to drive down costs and maintain high quality, AOI system offers you with cost effective solution and meet the requirements of every production facility. The system provides more than just inspection tools. They provide process improvement and correction guidance to help increase production efficiency.

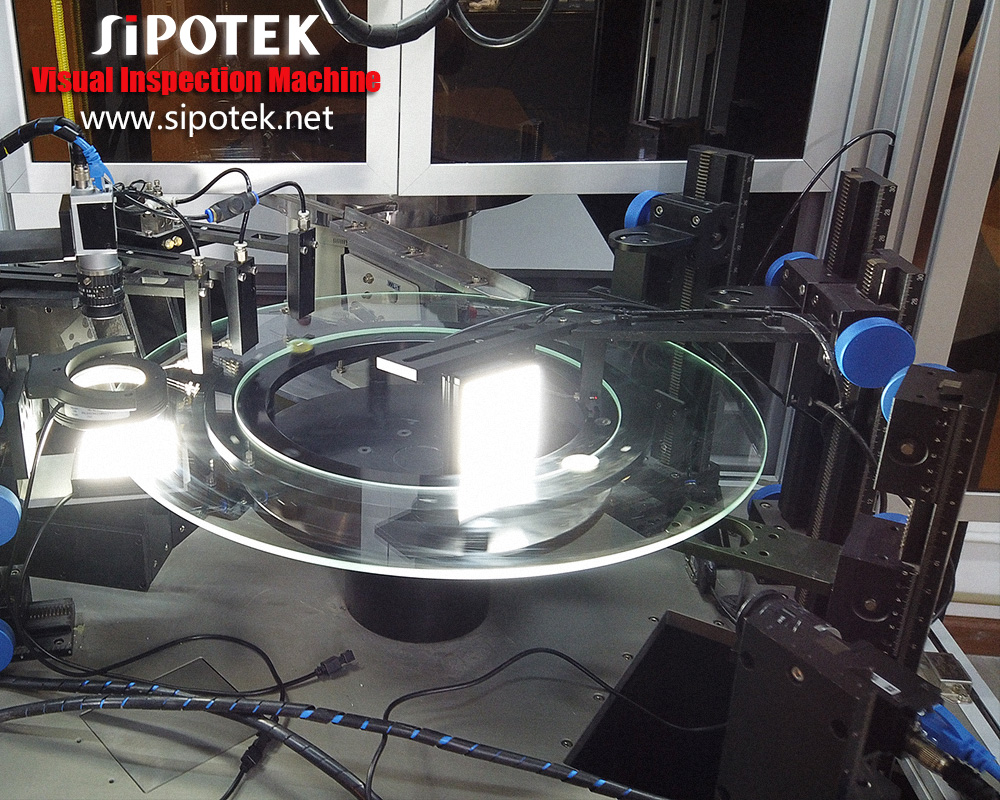

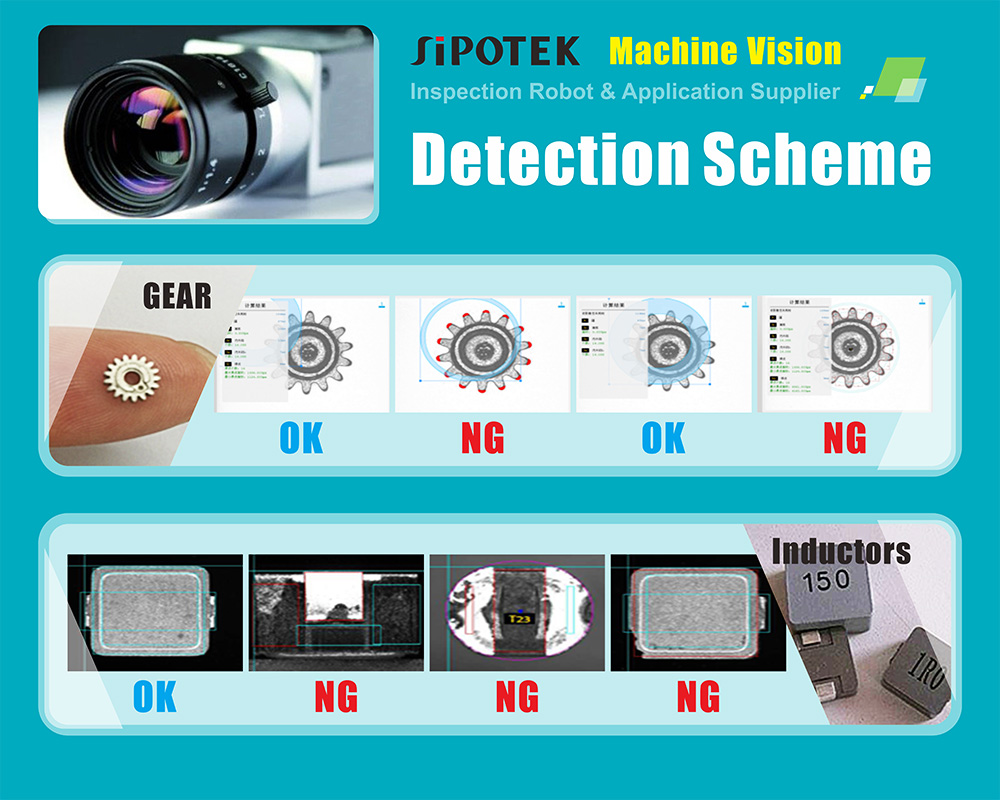

Nowadays, China has a large improvement in industrialization, intelligent machine research and manufacturing. Sipotek has 16 years of experience in machine vision research and manufacturing, base on the development of intelligent science, we self-create automate optical imaging sorting machine, which can be applied in precision hardware, electronic components, rubber rings, fasteners, plastic accessories, etc. The automated optical machine can not only pick out what is unqualified, but also can improve the whole production quality.

The essential image processing system is CCD industrial cameras. The system will be triggered automatically to capture what is ready to inspect from specific positions such as front, bottom, left side and right ride. The defects will be highlighted by the system and will be matched with qualified parameters. With negative recognition, the system will reject our the unqualified parts. This sorting procedure can improve production efficiency meanwhile inspect the parts under non-destructive condition. A standard CCD optical inspection sorting machine can inspection 500 pieces of small parts and can replace 8 workers to do the job.

Traditionally, the quality control (QC) work is done by staff detecting via naked eyes. During massive production, the QC staff can only pick small batch of the production and do the testing. The result is an estimated one. Most of the time, before small batch inspection, the worker has a primary inspection on the production line. There are some factors will influence the efficiency, such as people fatigue, and people emotions. An automatic inspection machine can address these concerns. It is a “worker” that can replace human work and can continue working in 24 hours if necessary. It’s the machinery inspector.

To learn how a aoi system can automate the production process, one can visit the website http://www.sipotek.net/ .

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/