Machine vision 2D technology been developed more than 30 years. The technology is relatively mature and widely usage in the filed of product quality control automation, but it has been difficult to meet the technology need in current situation.

Nowadays, the product quality on the market will require higher and higher accuracy, 3D machine vision technology is more popular with manufactures than 2D. 3D vision can measure the shape information and shape-related features such as the object flatness, surface angle and volume which 2D system do not have.

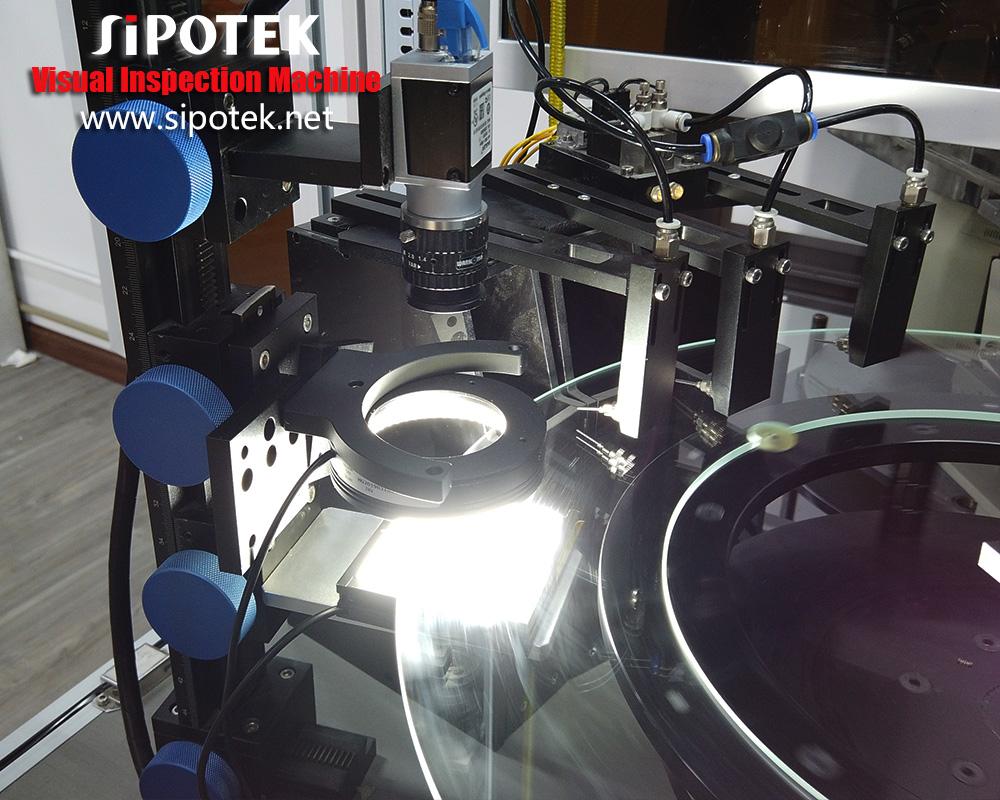

As the development of the automated industry, machine vision inspection technology are widely used in the filed of detecting, identify and other appearance defect inspection, for example, electronic components visual inspection, magnetic material visual inspection, plastic product visual inspection, printing product characters visual inspection, bar codes visual inspection, etc. These application cases have a common feature is that they all require mass product, high appearance quality requirement, high production effect and accuracy. Manual detection can not meet production need.

In the 1990s, in the face of such a huge production volume, the use of manual testing recruited a large number of testing staff, invested a lot of labor costs, training costs, etc.The cost of the factory invested in more, but can not effectively ensure the detection of products Pass rate. The visual inspection machine perfectly solves the single and repetitive work of manual detection. The automation capability, objective non-contact detection and high-precision detection of machine vision inspection equipment have become the preferred choice of manufacturers.

Machine vision inspection not only provides the product’s inspection pass rate, but also forms real-time data feedback, so that engineers can find the cause of defects in time, improve production accuracy and save production costs. As early as the 1990s, China’s machine vision technology began to develop. In today’s era of comprehensive development automation, the use of machine vision technology is becoming more and more important in the future. The great popularity of machine vision technology indicates the era of automation in the future.

All components in the 3D sensor are securely mounted on a single optomechanical assembly to ensure repeatability, focal length is locked in position relative to the transmitter and imager plane, and includes temperature compensation to correct for metal creep The movement. Another benefit of 3D machine vision is the ability to scan large objects such as truck frames with multiple scanners.

With the increasing application of artificial intelligence, deep learning is a popular trend in machine vision inspection, enabling computers to train and learn through architectures such as convolutional neural networks, process data and create patterns for decision making to mimic humans. The way the brain works. Deep learning technology will continue to play an important role in the next few years.

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/