Nowadays, inspection has become an important requirement during the manufacturing process to prevent poor quality products from being used in the value chain and from ultimately reaching-and potentially harming-the consumer.

Machine vision systems can safely help to yield significant benefits in the quest for improved quality including reduced scrap and rework, improved productivity, greater product reliability, increased consumer safety and greater customer satisfaction. As companies endeavor to increase quality and decrease costs, machine vision inspection may the next acceleration in the quest for perfection.

So why we choose to use machine vision for inspection our quality?

There are four main reasons for using machine vision:

- Accuracy. Machines have clear advantages in precision over the human eye. Even when humans rely on a magnifying glass or microscope, machines are still more accurate because they can “see” and measure parts to a tolerance of thousandths of an inch.

- Repeatability. Machines can conduct an inspection task over and over again in the exact same way without fatigue. In contrast, human inspectors tend to view an object slightly differently and may measure slightly differently each time, even if all the parts are exactly the same. Studies show that humans are 85% effective in visual detection of product quality concerns, while vision systems catch virtually 100% of these conditions.

- Speed. Machines can inspect parts faster. Particularly when inspection takes place at high speed, such as on a production line, machines offer an advantage in productivity and efficiency.

- Cost. Because machines are faster than humans, an automated inspector is worth several human inspectors. Machines also deliver higher uptime because they do not take breaks, do not get sick and are just as efficient in the middle of the night.

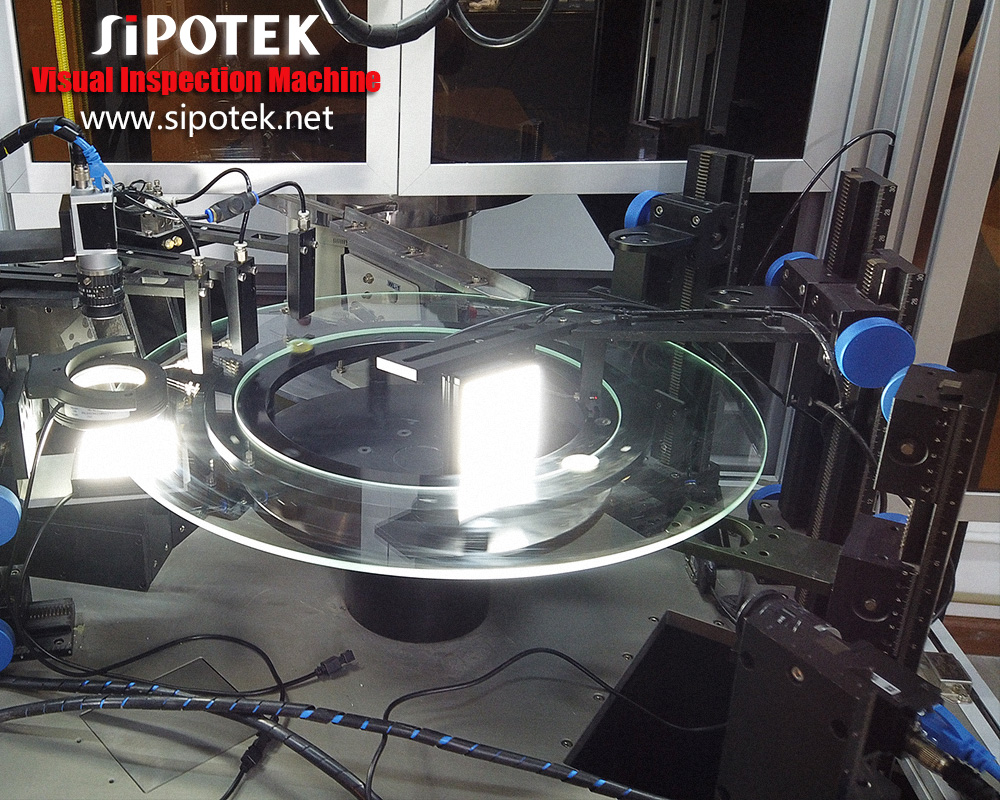

After a company determines the need for machine vision, the next challenge is to assemble the building-up of the system. The essential components include: lighting, part positioning, cameras, optics and control logic, image acquisition hardware, processing software and engineering services.

There are various components and system integration issues related to setting up a machine vision system. Most vendors are not expert in all of these areas, so look for a supplier who not only knows its core competencies, but has developed long-standing partnerships with other suppliers to provide other components needed for the system. Ask to speak to customers in the same industry, as well as in others that have successfully implemented machine vision inspection.

Sipotek focus on machine vision robots for over 16 years. Send us your requirement, return to you will be our inspection solutions!

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]