To find out why the vision inspection system can do the tasks in a quick and easy way, we need to know how the heart of the system works during the procedure.

Machine vision is a technology based on image processing methods that transmit the graphic signal to digital signal and achieve the recognition of qualified and negative parameters such as dimensions or defective types.

Different from computer vision revolved around image processing, machine vision, on the other hand, uses digital input and output to manipulate mechanical components. The devices that depend on machine vision are often applied in product inspection, where they often use digital cameras or other forms of automated vision to perform tasks by an operator. Acquiring images are important for machine vision systems, so the image machine part must contain a camera interface and a processor together with the acquiring tools. When these three components are combined into one device, we called it a smart camera, or an intelligent camera.

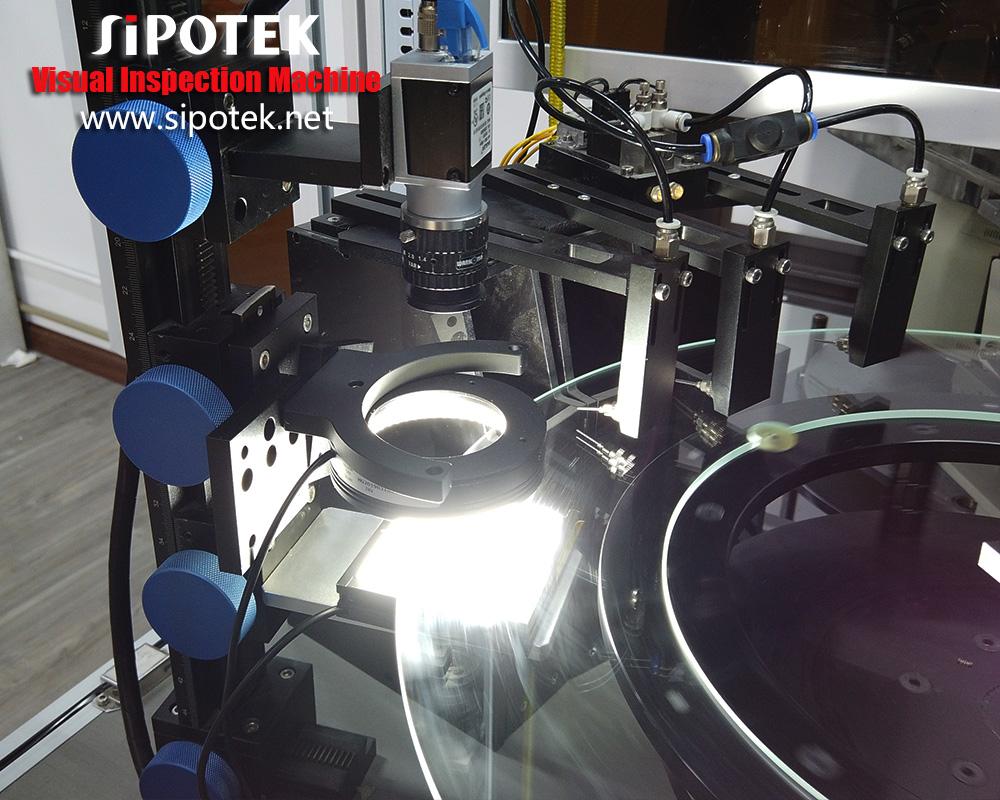

Now we have the smart cameras, next step, we need some additional components to complete the system. Input and output hardware mechanism, lenses, LED light sources, an image processing program, a sensor to detect and trigger the image acquisition and rejection mechanism. Although all of theses components serve their own functions, they still have a distinct role in a machine vision system when working together.

Take product inspection for your typical function using the machine vision system.

First, the sensor detects if a product is present. If there is indeed a product passing by the sensor, the sensor will trigger a camera to capture the images, and a light source to highlight key features. Next, a digitizing device called a frame grabber takes the camera’s image and translates it into digital output, which is then stored in computer memory so it can be manipulated and processed by software. Thomasnet introduced how this works.

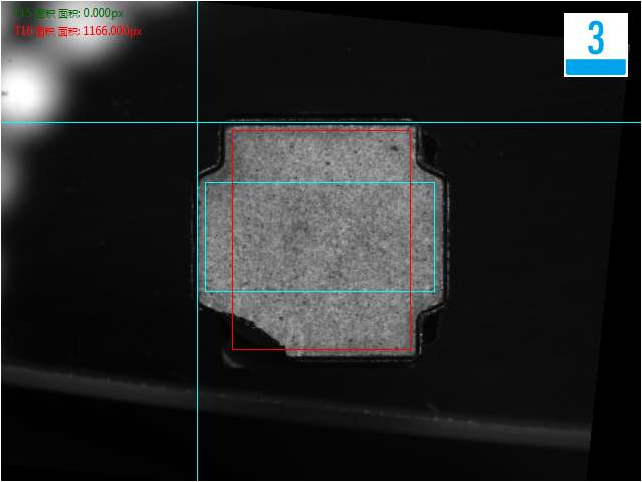

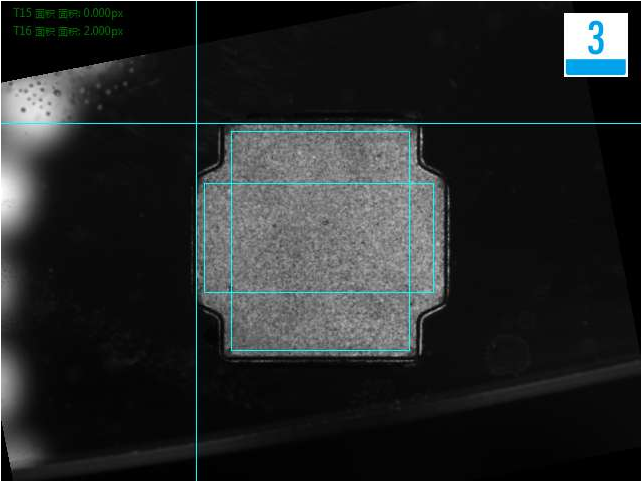

In order to process an image, computer software must perform several tasks. First, the image is reduced in gradation to a simple black and white format. Next, the image is analyzed by system software to identify defects and proper components based on predetermined criteria. After the image has been analyzed, the product will either pass or fail inspection based on the machine vision system’s findings.

Beyond product inspection, machine vision systems have numerous other applications. Systems that depend on visual stock control and management, such as barcode reading, counting, and store interfaces, often use machine vision systems. Large-scale industrial product runs also employ machine vision systems to assess the products at various stages in the process and also work with automated robotic arms. Even the food and beverage industry uses machine vision systems to monitor quality. In the medical field, machine vision systems are applied in medical imaging as well as in examination procedures.

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/