Electronic Component Production

Inspection Vision Systems

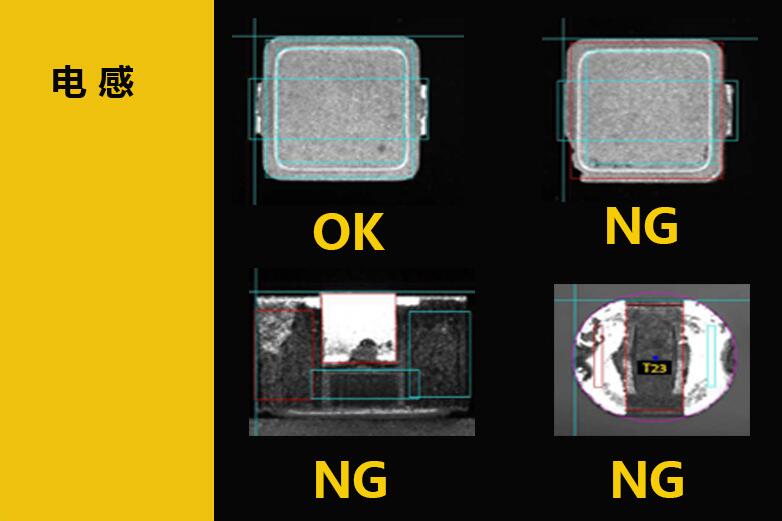

Electronic Component Inspection

The Machine Vision System detects defects in electronic components. Base plates for an electronic manufacturer’s components were inspected manually, which was a time consuming process with the potential for human error.

Sipotek fully automated this process that communicates directly to customer’s web service over Ethernet. Components are now imaged & inspected for all inspection attributes, eliminating human error from the process. Fail safe controls are in place to ensure defective plates are not permitted to pass down stream in the manufacturing process. Sipotek’s system revolutionized the inspection methodology & ultimately cut customer costs.

Manufacturers in both the consumer and industrial electronics markets rely on Sipotek machine vision solutions for quality control to meet stringent safety and quality standards.

Our systems are used across the complete supply chain – from electronic materials, components and passive components through to finished PCB and electronic equipment. We supply vision systems, smart cameras and AOI inspection machines for quality control inspection, part ID and control.

Typical applications include:

- Automated Optical Inspection (AOI) solutions

- Fiducial finding

- Surface mount placement and alignment

- Bent pin inspection

- Component verification – missing, incorrect or reversed

- Solder inspection and solder integrity

- PCB shorts, PCB voids, opens & misalignments

- Conformal coat and colour inspection

- Product defect detection

- Print and text quality inspection

- Feature presence verification

- Component code verification

- Surface inspection for contamination

- Product traceability

- Barcode and data matrix code reading

Get in Touch

Need expert help specifying your vision system requirements? Please contact Sipotek by filling in the form below and we will respond to you within 24 hours.