Wafer Inspection Scheme Shenzhen SPOTECK Technology Co., Ltd., SPOTECK has been focusing on machine vision inspection for 13 years.

There are a lot of testing cases, wide application areas, free sampling, development of testing programs, rapid outbound.

1. Contents and requirements of testing

Measure workpiece area:

Appearance and Dimension Detection of Samples 1.44mm in Length, 1.43mm in Width and 1.65mm in Height

Detection Contents: Damage, cracks, stomata, poor nickel layer

1: Bottom Positive Detection Appearance

2: Side Positive Detection Appearance

3: Side Positive Detection Appearance

4: Side Positive Detection Appearance

5: Side Positive Detection Appearance

6: Top Positive Detection Appearance

Note: The above detection items need to be clearly visible under the image to detect.

Detection efficiency: 250-350 pieces per minute (according to sample feeding speed).

Division of work: Subdivide the detection steps according to the detection content.

II. Equipment Composition and Major Institutions

Overall Composition: Dimension: 900*800*1850 mm

Model: SP_T300

1:SPOTECK Visual Detection Software

2: industrial computer

3: display 19 inches

4: Industrial cameras: 6 sets, 1 bottom, 4 side and 1 top.

5: Industrial Lens: 6 FA Industrial Lens

6: professional glass tray

7: solenoid valve

8: reducer

9: vibration cabinet

10: Feeding Equipment (Vibrating Disk, Direct Vibration, Controller)

II.1: 3-D Stereogram of Equipment Appearance

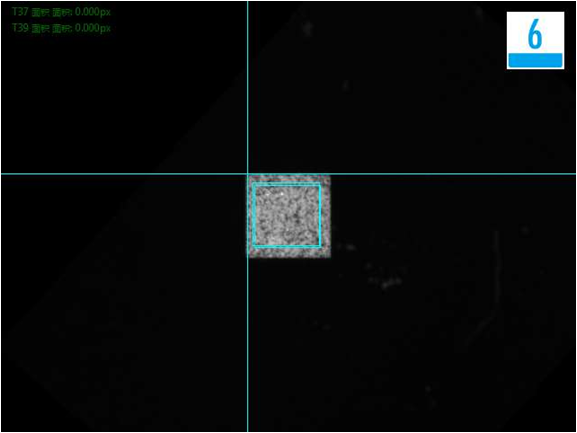

3:1 Bottom Positive Detection Method

Bottom Test Fine Product Analysis Chart: OK

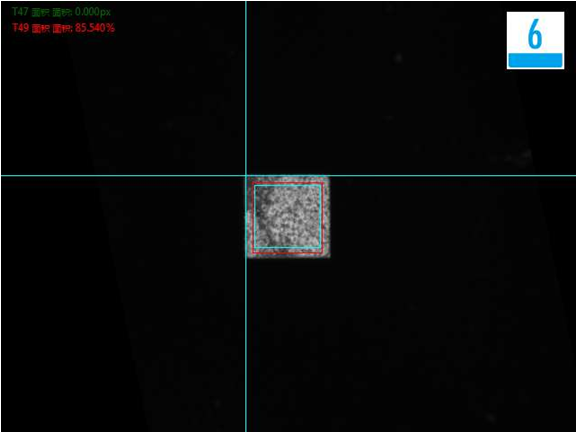

3:1 Bottom Positive Detection Method

Bottom defective product analysis chart (fission): NG

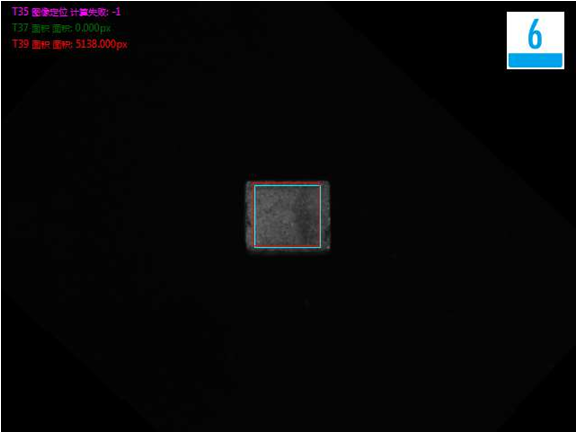

3:1 Bottom Positive Detection Method

Bottom defective product analysis chart (bad nickel layer): NG

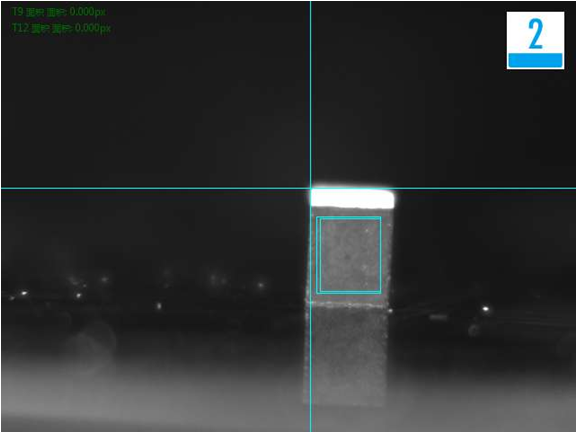

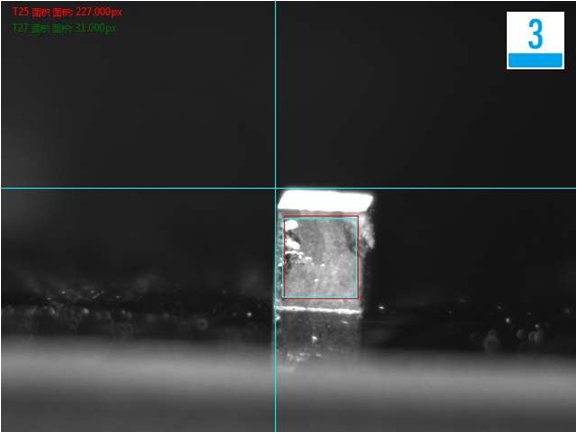

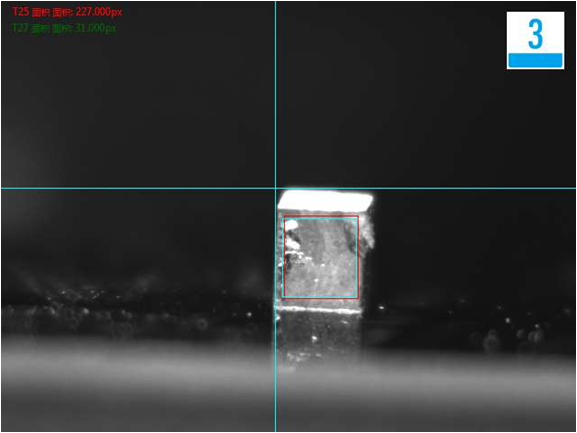

3:2 Side Positive Light Detection Method

Analysis Chart of Fine Products for Side Detection: OK

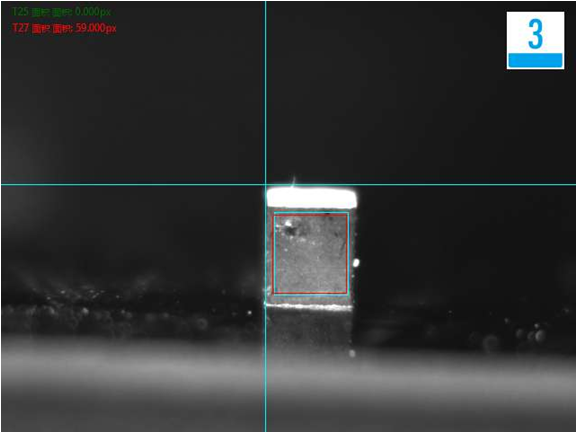

3:2 Side Positive Light Detection Method

Side detection defective product analysis chart (breakage): NG

3:2 Side Positive Light Detection Method

Top defective product analysis chart (stomata): NG

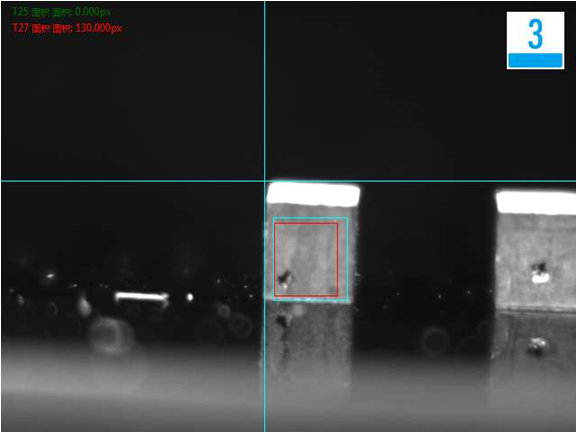

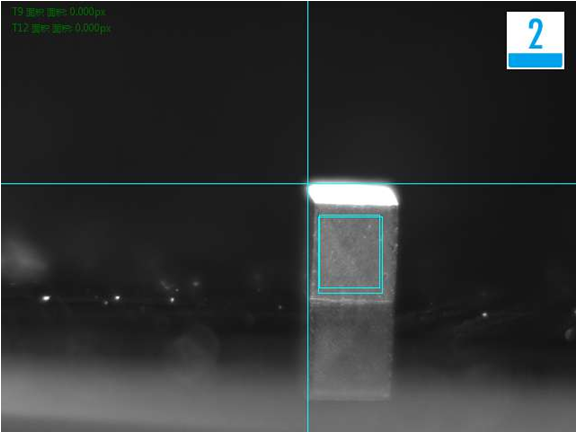

3:3 Side Positive Light Detection Method

Analysis Chart of Fine Products for Side Detection: OK

3:3 Side Positive Light Detection Method

Side detection defective product analysis chart (breakage): NG

3:3 Side Positive Light Detection Method

Top defective product analysis chart (stomata): NG

IV. System Installation Requirements:

Inspection space for equipment placement: Separately installing SP visual inspection system at the pipeline side, it is necessary to ensure that there is enough space to install the equipment.

Ambient temperature: 0-50 degrees Celsius;

Air humidity: below 90% RH;

Electronic jamming: Provide equipment with less electronic jamming.

Power supply: 220V, 50Hz AC, less than 1KVA power consumption, air pressure 0.35-0.7MPa

Above is the wafer detection scheme, the main contents of detection are breakage, cracks, pore, poor nickel layer and size.