Machine Vision Inspection Scheme for Round Hardware Parts Shenzhen SPOTECK Technology Co., Ltd.

SPOTECK has been focusing on machine vision inspection for 13 years. It has a wide range of applications and many detection schemes.

1. Contents and requirements of testing

Measure workpiece area:

Detection of Cylindrical Samples with Integral Height of 4*2.5mm

Content of detection:

1: Bottom detection of edge notches, holes and diameters

2: Total Height of Side Detection

3: Top test diameter, with or without holes

Note: The above detection items need to be clearly visible under the image to detect.

Detection efficiency: 200-400 pieces per minute (according to sample feeding speed).

Division of work: Subdivide the detection steps according to the detection content.

II. Equipment Composition and Major Institutions

Overall Composition: Dimension: 900*800*1850 mm

Model: SP_302C

1:SPOTECK Visual Detection Software

2: industrial computer

3: display 19 inches

4: Industrial cameras: 3 sets, bottom and top detection diameter, with or without holes, edge incisions. Side detection height

5: Industrial Lens: 3 FA Industrial Cameras

6: professional glass tray

7: solenoid valve

8: reducer

9: vibration cabinet

10: Feeding equipment (Vibrating disc, Direct Vibration, Controller).

II.1: 3-D Stereogram of Equipment Appearance

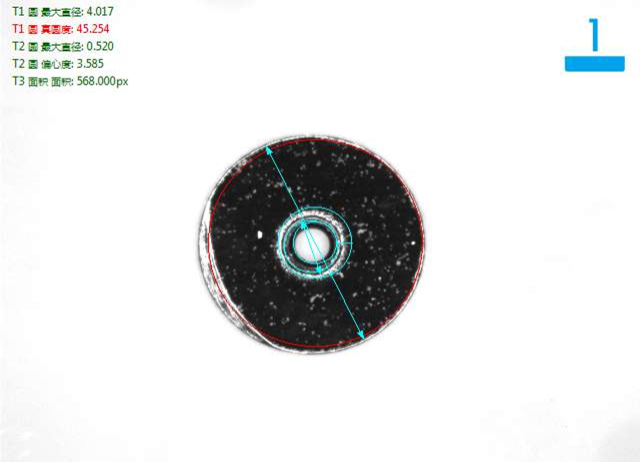

3:1 Bottom Detection Method

Bottom detection effect original picture:

3:1 Bottom Detection Method

Bottom Test Fine Product Analysis Chart: OK

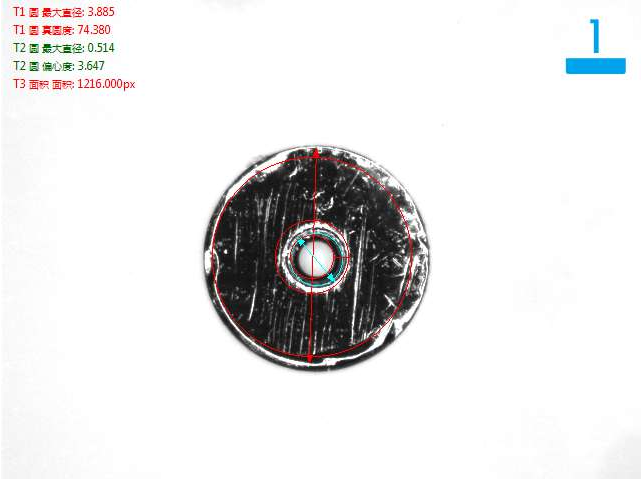

3:1 Bottom Detection Method

Bottom detection edge incision defect analysis chart:NG

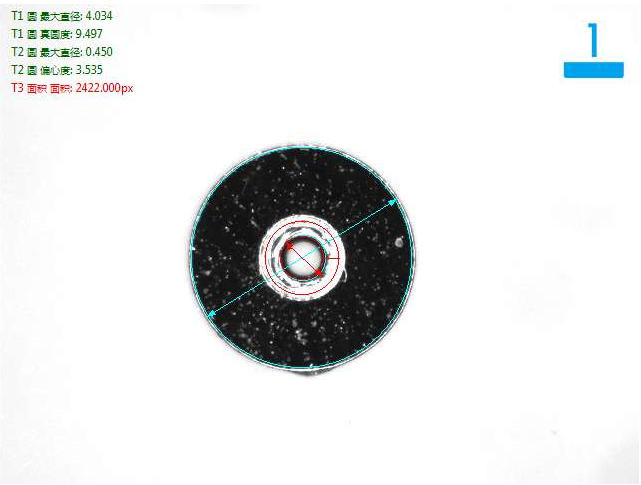

3:1 Bottom Detection Method

Bottom Inspection Inner Hole Excessive Bad Product Analysis Chart:NG

3:1 Bottom Detection Method

Bottom defective product analysis chart: NG

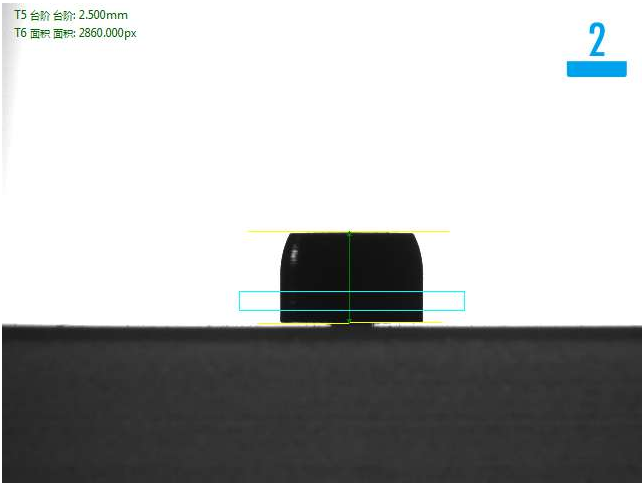

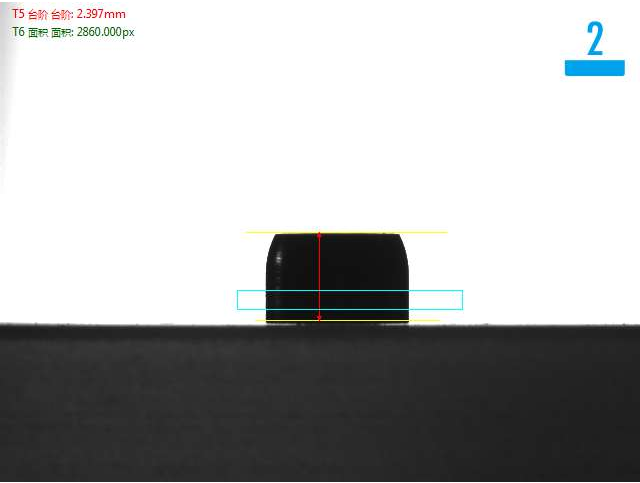

3:2 Side Detection Method

Analysis Chart of Fine Products for Side Detection: OK

3:2 Side Detection Method

Analysis Chart of Highly Bad Products for Side Detection: NG

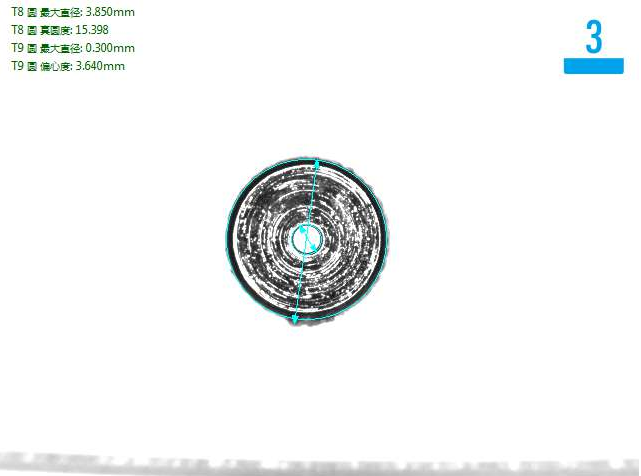

3:3 Top Detection Method

Top test product analysis chart: OK

IV. System Installation Requirements:

Inspection space for equipment placement: Separately installing SP visual inspection system at the pipeline side, it is necessary to ensure that there is enough space to install the equipment.

Ambient temperature: 0-50 degrees Celsius;

Air humidity: below 90% RH;

Electronic jamming: Provide equipment with less electronic jamming.

Power supply: 220V, 50Hz AC, less than 1KVA power consumption