With the development of the market, the demand for consumer electronics and other products has increased greatly in recent years so the demand for small hardware parts has also been rapidly promoted. Hardware parts refer to machine parts or components made of hardware and some small hardware products. It can be used alone or as an aid. In the field of industrial manufacturing, it is very important to inspect the parts. A small part production quality problem can damage the overall performance of the whole equipment, and even affect the overall safety issues.

In the process of hardware parts production and processing, there will inevitably be some problems that must go through the inspection process to avoid the inflow of defective products into the market. Due to the disadvantages of slow speed, low efficiency and high cost of manual inspection, more and more factories are introducing machine vision inspection technology.

The greatly increased production demand poses two major challenges for inspection – how to efficiently complete the inspection and measurement of high-volume parts? How to effectively avoid human measurement errors?

How to detect product appearance defects:

It is composed of an automatic loading system, transmission and positioning system, automatic measuring system, automatic sorting and discharging system, measurement and control system, and computer data processing system, which can automatically inspect all kinds of hardware parts. Its workflow is as follows:

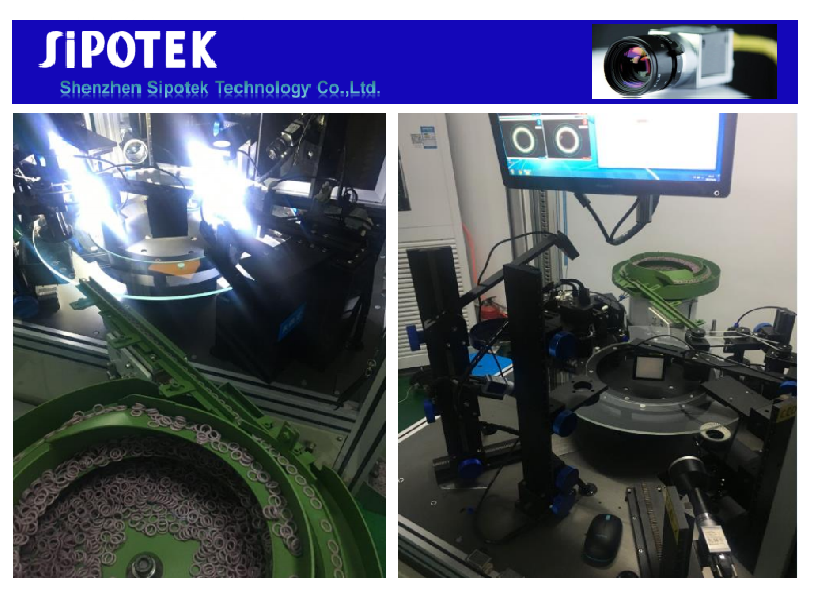

- Arrange hardware in an orderly manner by vibrating the tray and conveyor belt, conveying them to the front of the linear track and into the rotating glass tray.

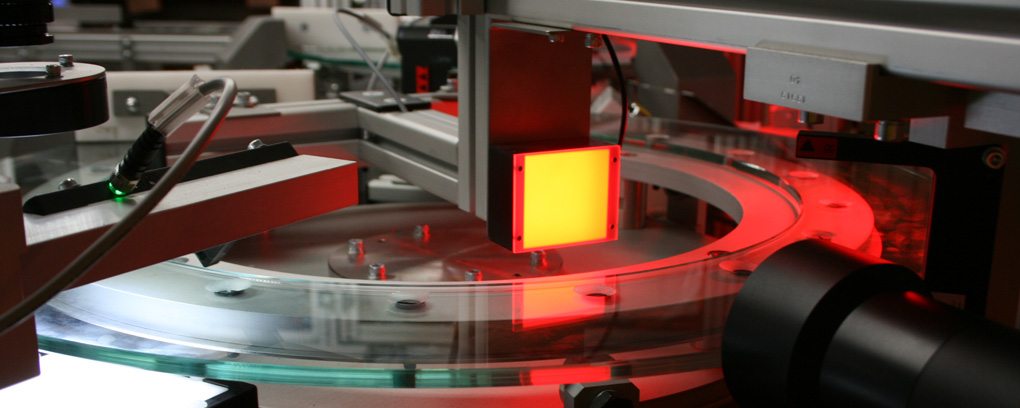

- Glass plate running to bring the hardware under the camera to take pictures.

- Photos are transferred to the vision software system for high speed, high precision and high stability in real-time inspection, analysis and calculation, detecting specific defects and distinguishing between good and defective products.

- Finally, the system controls the action of the equipment on-site according to the result of the discrimination, and the defective products are automatically rejected.

- At the same time, the system will also carry out statistics on all testing results, and record the number of hardware and the number of unqualified hardware, which is convenient for real-time monitoring of product quality and facilitates later management and traceability.

It can be found that, compared to the traditional manual visual inspection operations, the hardware inspection screening machine to detect product appearance defects is more high-speed, efficient and accurate.

Application of machine vision inspection technology in the field of hardware fittings:

The machine is visual inspection, is through the machine vision products (i.e. image ingestion device) will be ingested target into an image signal, transmitted to the special image processing system, according to the pixel distribution and brightness, color and other information, into a digital signal; image system to these signals for various operations to extract the characteristics of the target, and then according to the results of the discriminatory to control the action of the equipment on site.

Machine vision inspection technology is widely used for dimensional inspection of hardware parts, surface defect detection, character recognition detection, etc.

Visual inspection in hardware parts visual inspection applications mainly include two aspects:

1. Precision measurement. Usually used to detect length, straightness, flatness, perpendicularity, etc. It is mainly used to measure the data related to the size of the workpiece.

2. Precision detection. Equipment can be fast and accurate detection of defects and flaws in the appearance of precision parts and has a high degree of repeatability.

Dimensional inspection: Machine vision can measure and inspect the length, width, diameter, hole distance, inner and outer diameter, tooth distance and other dimensions of hardware fittings.

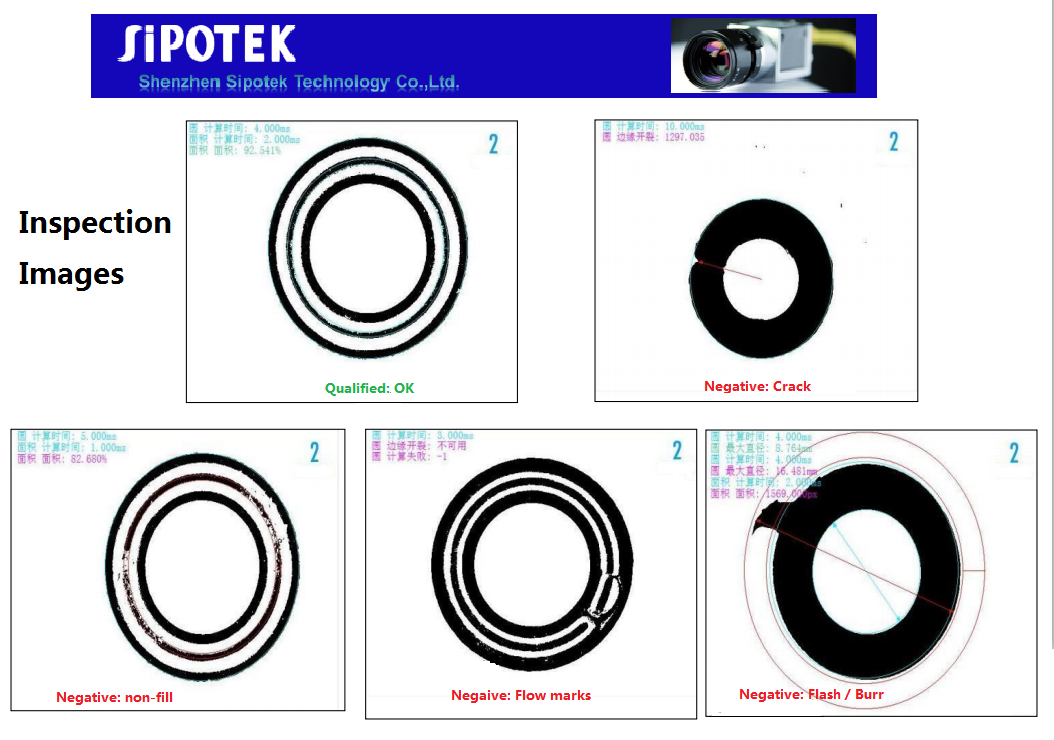

Surface defect detection: Machine vision can detect defects such as scratches, scuffs, pits, chips and cracks on the surface of hardware parts.

Case Study:

Round hardware defect detection

For different inspection needs, the machine vision inspection difficulty also has a high and low. Flat hardware stamping parts are relatively easy to detect while non-standardized irregular workpieces with more peculiar shapes are more difficult to detect and require special customized services. In any case, when purchasing machine vision inspection equipment, factories must confirm their needs and have detailed and in-depth discussions with the equipment supplier.

If you want to learn how a visual inspection machine can automate the production process, please visit the website http://www.sipotek.net/ .

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Email: [email protected]

Website: http://www.sipotek.net/machines/