Techopedia explains that a machine vision system (MVS) is a type of technology that enables a computing device to inspect, evaluate and identify still or moving images. It is a field in computer vision and is quite similar to surveillance cameras, but provides automatic image capturing, evaluation and processing capabilities.

Machine vision is also known as “industrial vision” or “vision systems”. The machine vision system can consist of a number of cameras, sometimes mounted over assembly lines to inspect products, capture data, read labels, direct product, and more, all without human intervention.

The wiseGEEK illustrates that machine vision is an interdisciplinary sub-field of engineering. It has to do with engineering the necessary hardware and software for a machine vision system that has useful industrial applications. The most frequent applications are quality control and product counting. As machine vision advances as a field, it automates some of the most boring industrial jobs, permitting human employees to serve in more interesting jobs.

Knowing more about machine vision, we should consider the basic concept of what is the machine vision tool.

The machine vision tools are a means of identifying the what allows a computer to read visual displays. Considered the visual equivalent of voice recognition, machine vision will employ one or more video cameras, and analog to digital conversion and digital signal processing components. The data received by use of these tools is routed to a controller, making it possible for the computer to “see” the data.

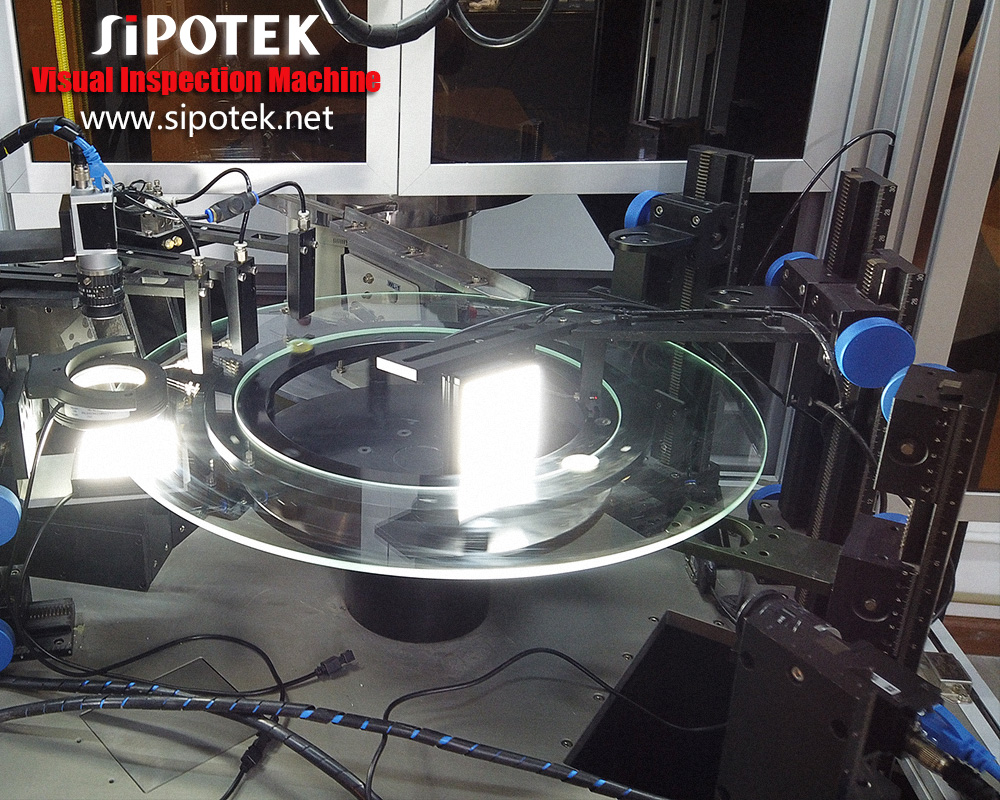

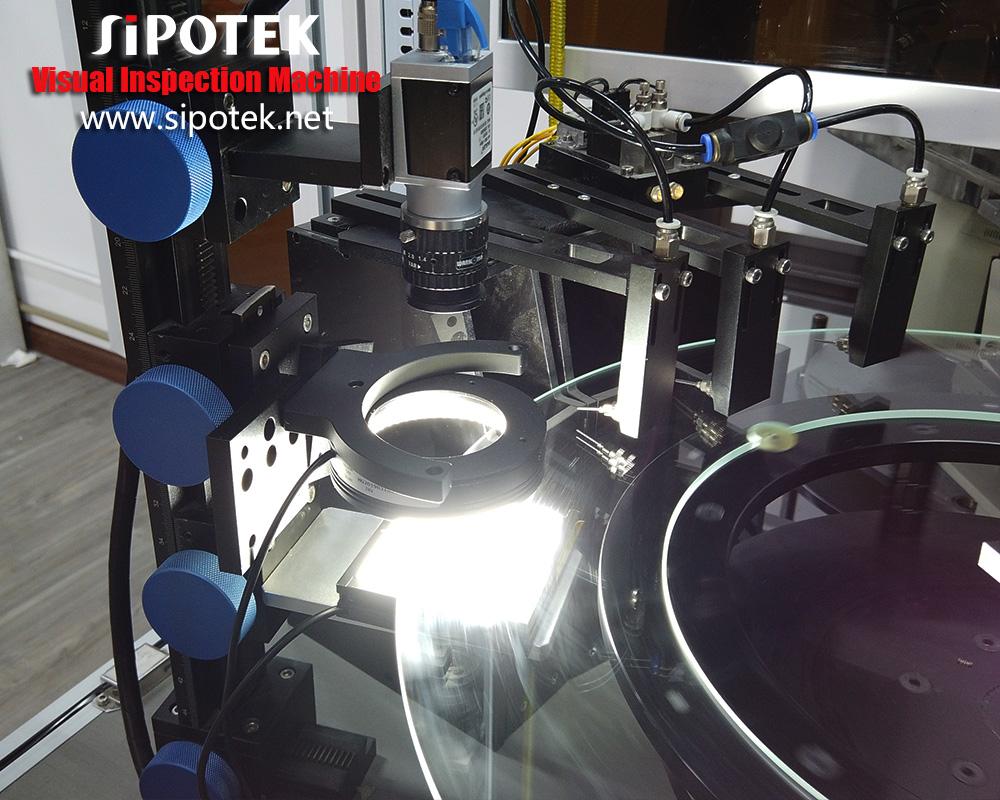

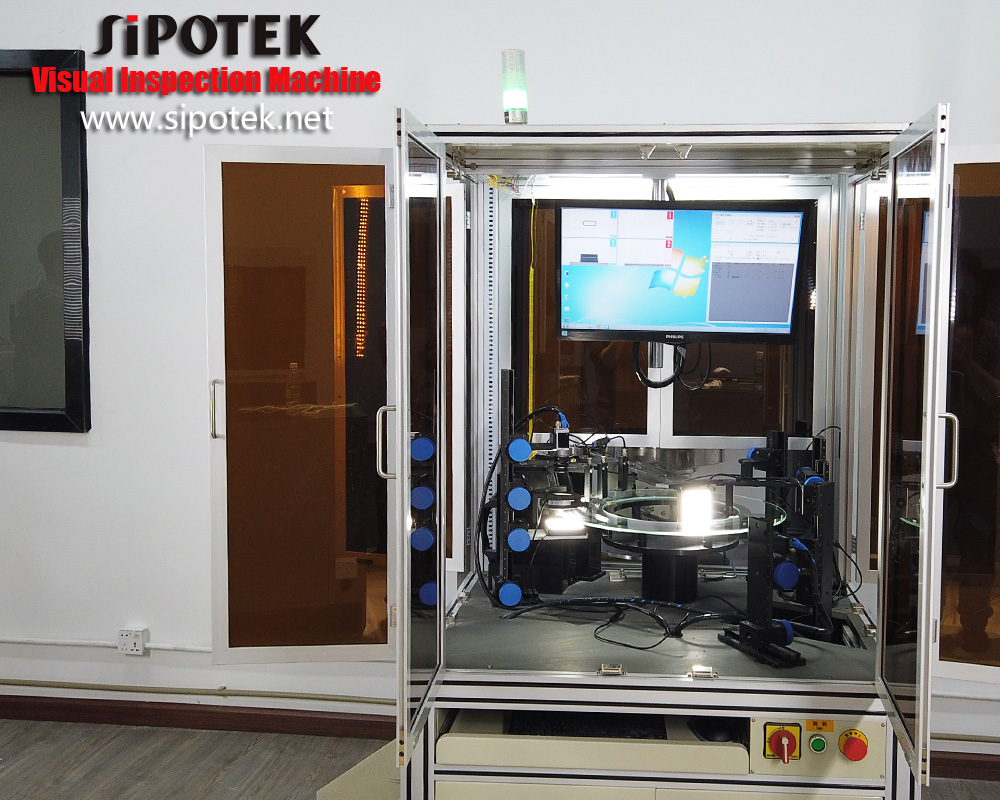

Sipotek Visual Inspection Machine 31

Like many different types of vision systems, machine vision takes into consideration two important aspects of relaying the visual data.

- First, there is the issue of sensitivity to light conditions. The tools utilized to achieve machine vision must provide the ability to capture the data even in dim light, as well as detect impulses at invisible wavelengths that are decidedly weak.

- Second, machine vision tools are concerned with resolution. The capturing and processing of visual data requires that all objects within the range of view are clearly delineated. Achieving the ideal mix between sensitivity and resolution requires some adjustment from one instance to the next.

The use of machine vision tools today is common with many types of industrial and medical applications. Machine machine has proven to be very helpful where there is a need to identify counterfeit objects, such as a forged signature or counterfeit currency. Handwriting analysis is another function that has benefited greatly from the advances in machine vision. The textile industry employs machine vision as a means of inspecting pattern and dye consistency on fabrics and materials produced. Machine vision has also enhanced the ability to capture images for use in diagnosing medical issues.

Machine vision is considered a sub-field of computer vision in general, which includes neuron-computational investigations into human vision and the development of flexible vision systems for autonomous robotics. It has the connotation of application in industrial settings. Machine vision is used in any industrial setting with a significant degree of automation, where product specs are well-defined and products are mass produced. This includes the automobile industry, the semiconductor industry, and the electronics industry in general.

Sometimes, a machine vision system is coupled to a robot arm that discards defective products or even actively participates in manufacturing the product.

About our company

Sipotek Visual Inspection Machine

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-18617182707

Email: [email protected]

Website: http://www.sipotek.net/