Contemporary industrial control automated production always advocated high-efficiency methods, and traditional manual inspection and testing can no longer meet massive production requirements. The advent of machine vision is applied well during the development trend of contemporary production methods. With its advantages such as accuracy, repeatability, high speed, universality, and low cost, it has been applied in many industries, especially in inspection process at the technical level. Let’s talk about the characteristics of automated machine vision inspection.

Automation machine vision is used to Improve production flexibility and automation technology level. In some places such as working environment and the place where is not suitable for artificial visual, manual work will has a high risk and machine vision will be used instead of artificial vision in those situation. In addition, in the process of massive industrial production, machine vision inspection can increase production capacity and reduce costs to a large level. It can work continuously for 24 hours and implement 100% on-line inspection at high speed. The accuracy of the inspection is also close to 100%. Therefore, many industries choose machine vision inspection technology to maintain online high-precision, high speed and accurate measurement in many places.

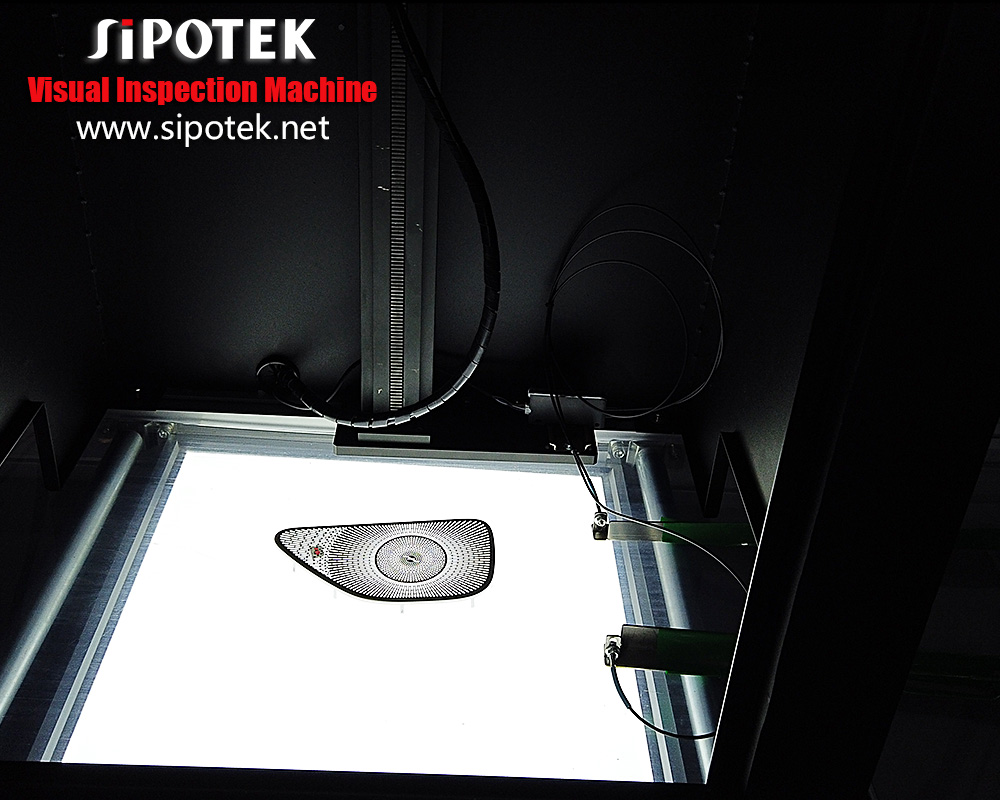

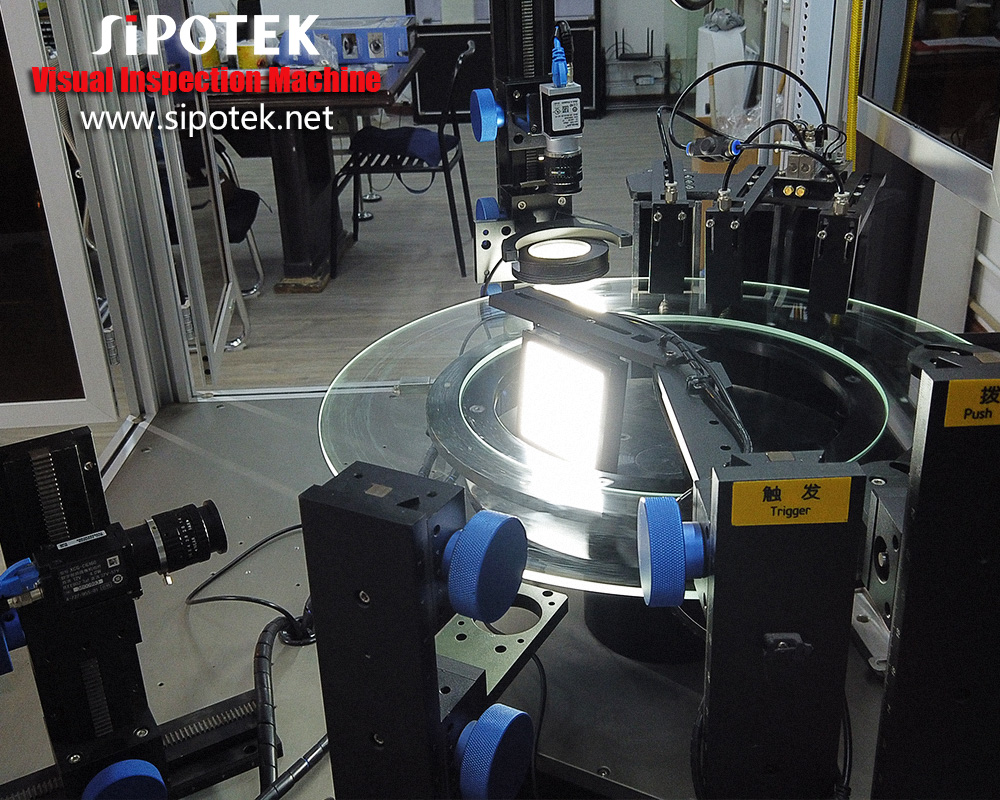

Sipotek Visual Inspection Machine 36

The development trend of machine vision has so far not been a single application commodity. The hardware and software products of machine vision have gradually formed a necessary part of each link of production and manufacturing process. This has clearly put forward higher regulations for the integration of system software. SIPOTEK’s long-term focus is on machine vision image collection technology products by scientific research and development design. With the accumulation of many years of working experience, SIPOTEK grasped key technologies related to the vision industry such as excellent image collection and solution technology, machine vision, image processing and optimization algorithms, and has several independent product development machines Vision inspection equipment. Among them, the MV-BDP200s machine vision transmission belt transmission test software development platform can maintain a smooth, continuous, and reliable product quality inspection, helps to get rid of the defects of manual inspection, such as fatigue, individual differences, and poor repeatability. By using machine vision solution, production efficiency is increased and production cost is reduced.

Inspection technology is one of the basic technologies for intelligent industrial production, and it is important to ensure product quality. With the development trend of processing manufacturing industry, machine vision will gain greater development trends and universal application, and become the mainstream product application of automated inspection technology.

Sipotek Visual Inspection Machine

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-18617182707

Email: [email protected]

Website: http://www.sipotek.net/