As we all know, due to the influence of the processing technology, the appearance defects in the charging head of the mobile phone show various states. This brings great difficulty to the defect detection of the charging head. With the continuous improvement of product quality standards in the market, manufacturers have put forward higher requirements for the appearance quality of products, and some mobile phone manufacturers have reached the micron level for defect detection standards. For such high-precision product quality inspection, manual inspection is difficult to apply. Therefore, machine vision inspection has become an important means and basis for the appearance defects inspection of mobile phone charging heads.

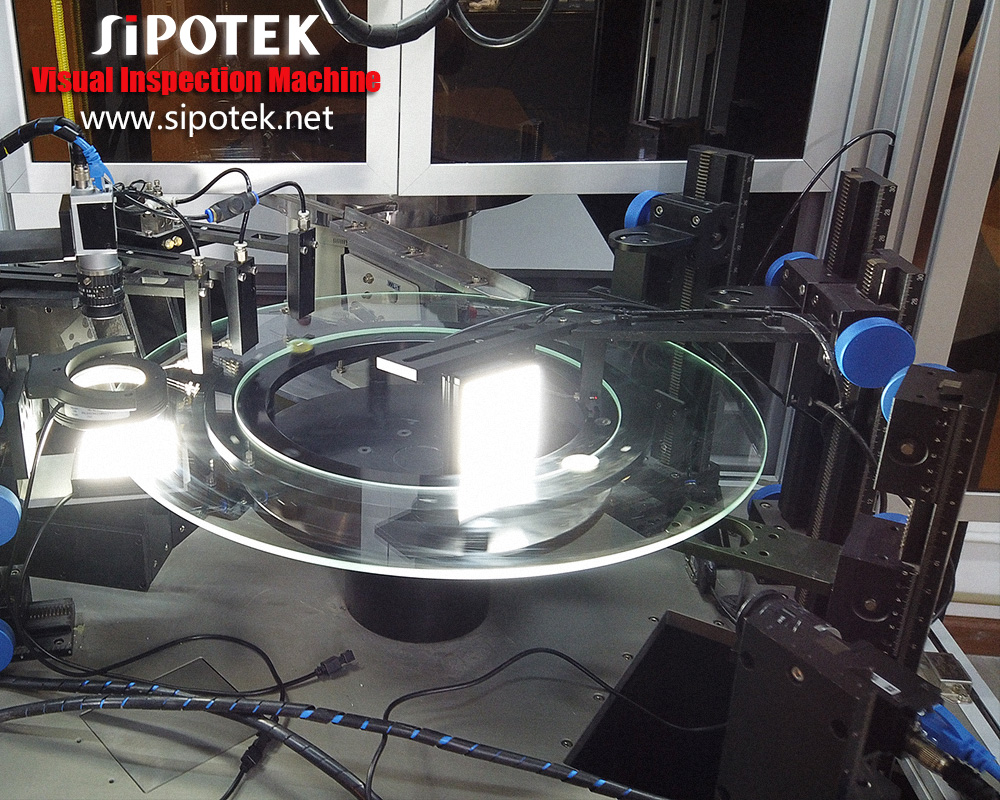

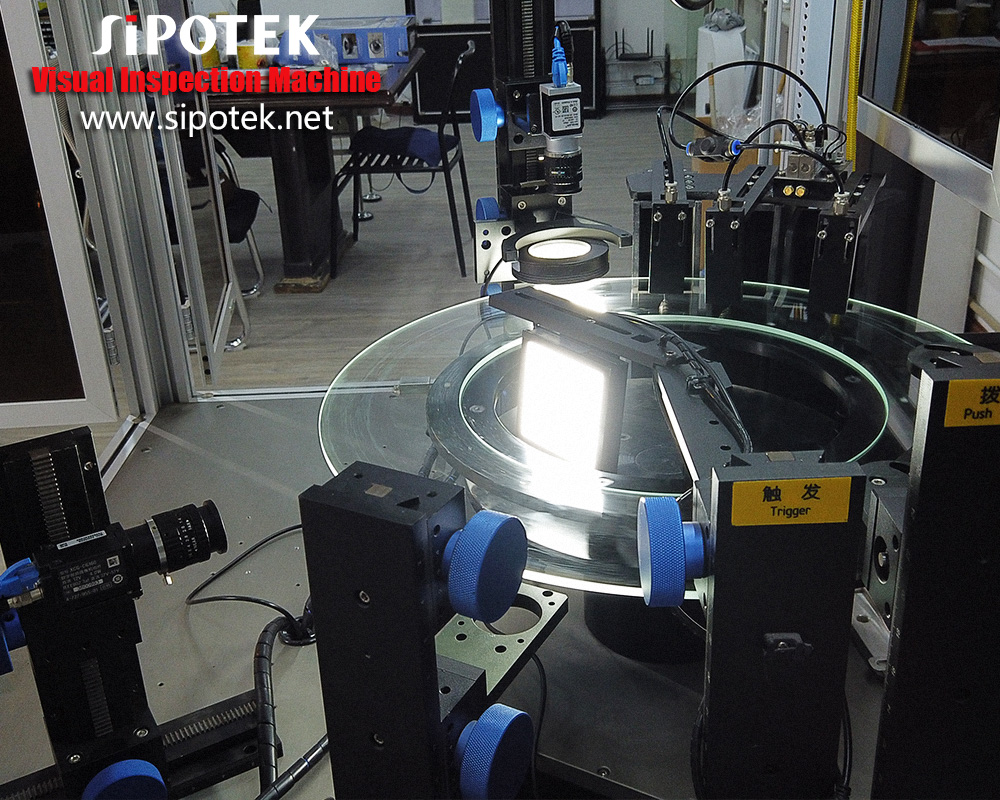

Appearance inspection machine of charging head of SIPOTEK Technology

Aiming at the problems of black spots, different colors, scratches, burrs, blackened iron parts, and broken iron parts in the surface defects inspection of mobile phone charging heads, Shenzhen SIPOTEK Technology uses a high-speed turntable visual inspection machine to detect the appearance defects of mobile phone charging heads. Detection provides a rapid vision inspection solution.

The mobile phone charging head appearance inspection solution is equipped with high-precision industrial cameras, telecentric high-definition optical industrial lenses, customized optical adaptive light sources, and professional optical glass inspection platform. Through panasonic servo motor and PLC operation system, keep the product always at a fixed speed in motion. With the high uniformity light source, the industrial camera can capture the pictures of the product with high quality and uniform appearance of the mobile phone charging head.

Equipment advantages: error rate <0.1, missed detection rate <0.1%; yield rate 99.99%; work efficiency 150-200 pieces/min.

The testing software independently developed by SIPOTEK can automatically determine the results of OK/NG, defect location, defect determination type,defect area, and count the good products, yield rate, defective products, defective rate, number of defect type according to the test results. It can be exported uniformly through the Excel record table, the test results can be stored for a long time, and data analysis can be provided for quality control. For product customization, similar products only need to replace the corresponding testing tools, saving time and effort.

The effect of automated vision inspection machine on mobile phone charging head

- Instead of manual labor

- Long-term return on one investment without labor and management costs

- 7X24 hours uninterrupted work

- Consistent judgment criteria, no subjective judgment

- Defects beyond the judgment of the processor

- High accuracy and repeatability

- Compared with traditional machine vision, it has higher detection accuracy, the judgment standard of appearance is closer to the judgment standard of human eyes, and has more reliable repeatability than human eyes

- Automation

- Configure automatic loading and unloading to automate the inspection process. The production line is connected to further improve the measurement efficiency.

Every detection link and software analysis link of the charging head appearance inspection solution of SIPOTEK are reducing costs for customers, improving detection efficiency, and bringing great value to customers.

If you want to learn how a visual inspection machine can automate the production process, please visit the website http://www.sipotek.net/ .

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/machines/