The automobile industry is one of the early industry that applied machine vision technology. It has high requirements for automobile production in parts manufacturing and assembly. As a high-tech industry, it requires a variety of advanced automation technologies to ensure efficient production. At present, many sections of automobile manufacturing have been operating by automatic machine equipment, which is free from manual operation. But in order to ensure the correctness and qualification of each assembled part, a reliable detection technology is needed. Machine vision is currently a high recognition technology in industrial production, with its unique application advantages, it can be widely used in the automotive industry.

The practical application of machine vision in the automotive industry mainly has the following major parts.

First part, the car assembly and parts testing

- Component size, appearance, shape defect detection;

- Assembly component error, installation, direction, position detection;

- Reading code, model, production date detection;

- The final assembly cooperates with the robot welding guide and quality inspection;

- Electrical property testing and functional testing;

- Intelligent transportation, license plate recognition.

Second part, seat belt roller detection:

- The detection of shaft length tolerance, wheel bent, groove burred;

- The precise positioning of the mechanism;

- Large depth of lens for clear burr observation;

- The system detection accuracy is 0.2mm, and the detection speed is 30 PCS/Min.

Third part, car lock assembly detection system:

- Parts missing detection, type detection;

- Any number of parts inspection;

- Worm gear and worm gear angle;

- The system automatically switches 38 product programs according to foreign signals.

Fourth part, car control layout detection system:

- Detect panel button assembly, button laser engraving size;

- Large area array camera improves detection accuracy;

- The automatic system ensures that no faulty parts flow out;

- Words right and wrong, position detection.

Five part, wire harness fuse box (Xingming standard equipment)

- 40 thousand consecutive tests were not misjudged or wrong-judged;

- The right or wrong character, color and position;

- The barcode reader used different product programs;

- Print result of correct results after test completes;

- Label the correct product.

Sixth part, car dashboard detection:

- Instrument panel pointer angle detection, indicator color detection;

- A single camera observes the digital display of the LCD screen;

- The color camera measures the color of each indicator light;

- The lighting mode is compatible with all shapes of dashboards;

- Functional testing while performing image inspection.

Seven part, fuse detection system

- Fuse resistance blocking detection;

- Whether there are gaskets or nuts;

- Freely switch products;

- The system is stable and the detection ensures a zero false positive rate.

Eight part, engine testing:

- Machining position, shape and size, including arc;

- Timing chain position detection;

- Piston marking direction and model detection;

- Crankshaft connecting rod code, character, model detection;

- Dispensing detection;

- Cylinder, cylinder head reading code, character, model detection;

- Database trace.

Nine part, dispensing detection system / such as engine applications

- It can detect any width of the glue track;

- The glue can be transparent;

- The robot hand grasps the product and tests it according to the booking trajectory;

- Multiple cameras capture image and process at one time;

- A camera moves while taking pictures.

The application of machine vision inspection technology in the automotive field mainly plays the role of defective detection, dimensional measurement, visual guidance and positioning, etc. It has great significance for improving the overall quality and improving efficiency of the automobile, and has an indispensable key technology for the automotive industry.

For more Machine Vision Inspection Machine information, please visit http://www.sipotek.net

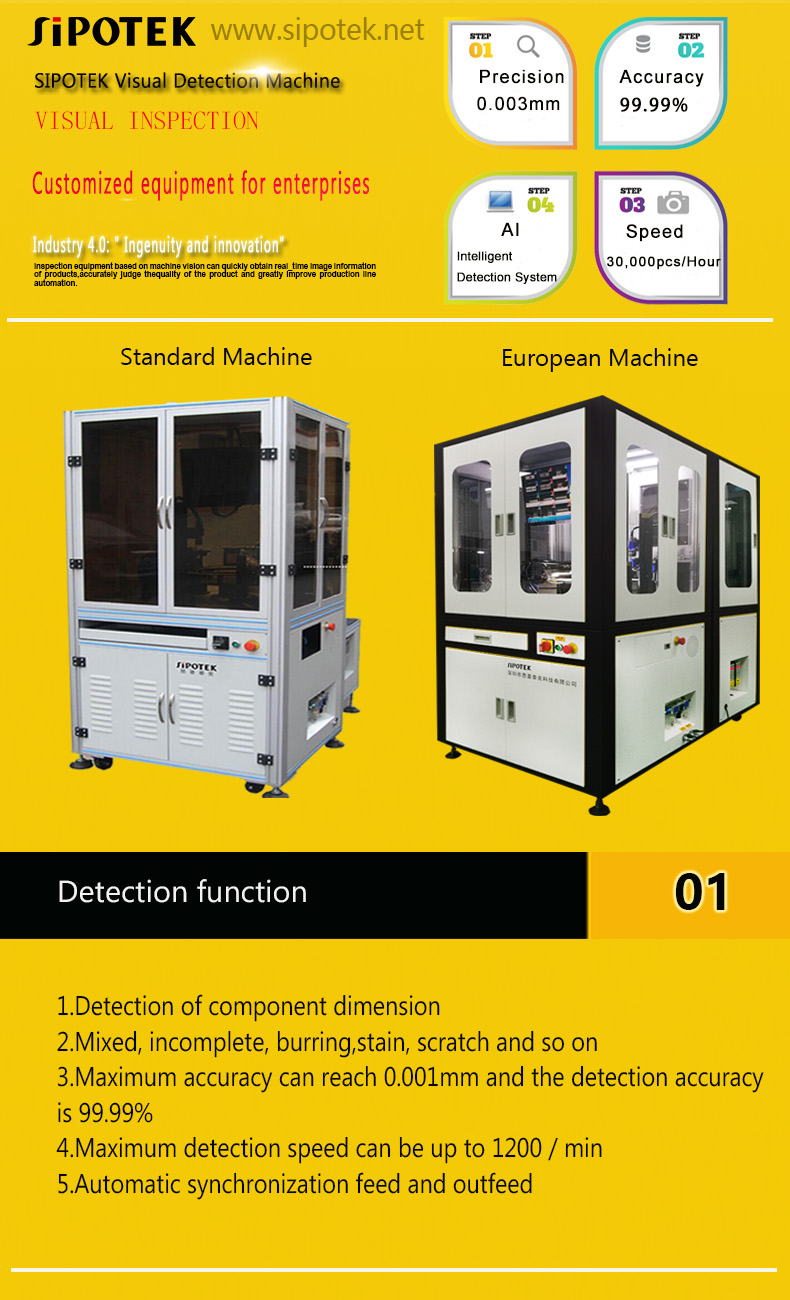

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/