Sipotek is a professional china automated optical inspection machine manufacturers located in shenzhen city,major products including visual inspection machine and automated optical inspection (AOI) machine.

Today china automated optical inspection machine manufacturers will tell you the understanding of visual inspection machines for automation

Automation is the term used to refer to the process by which machines, equipment, processes or systems (management and production processes) are basically detected, judged, analyzed, processed, and controlled to accomplish the desired objective without direct involvement of one or more persons, according to the needs of the man.

In the past, individuals proposed this initiative, many of them thought it was a skill that was transformed from one manual operation to another manual operation by means of machines. With the dissemination and application of the initiative, industry expects are starting to discover that, in reality, the initiative is not just an ordinary change of operational tools, but also a complete replacement of mental, physical, and human work and can work actively.

Nowadays, automation of the artificial “join” vision has made the initiative a complete and independent system and has also broadened the scope of artificial vision capabilities.

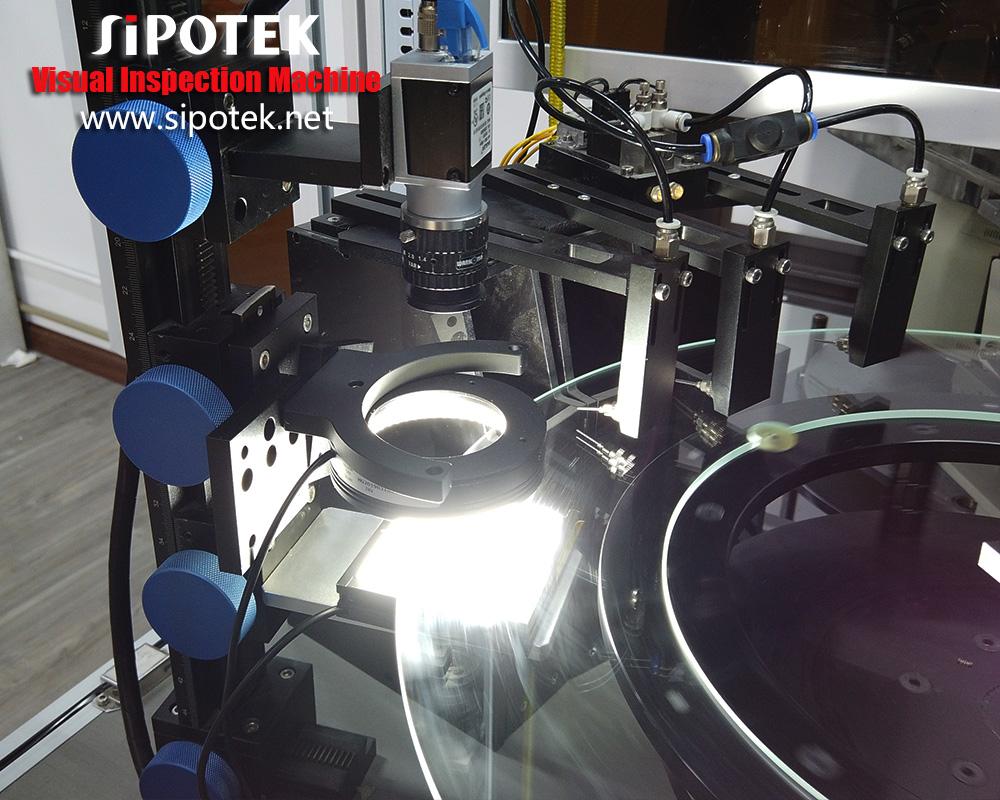

We understand that the Visual inspection machine mainly includes a light source, a high speed camera, a lens, an image acquisition card, image processing software, and so on. Its principle of competence is to use its machine of sensory vision to realize the function of visual recognition of the human eyes. If we say this first in people’s understanding, the initiative has the hands and the brain; now, because of the behavior of the initiative to “unite” the artificial vision, we can say that it is for the capacity of initiative and the eyes. A machine with eyes, brain, and hands can replace human resources and accomplish tasks on its own.

The result of the general trend is the substitution of the manual inspection with automated visual inspection machines. Why is that? This can be analyzed under the three following areas:

First, producers face difficult employment situations and high wages. They have to spend more and more on the job market. Automated visual inspection can be considered a labor saving means by manufacturers.

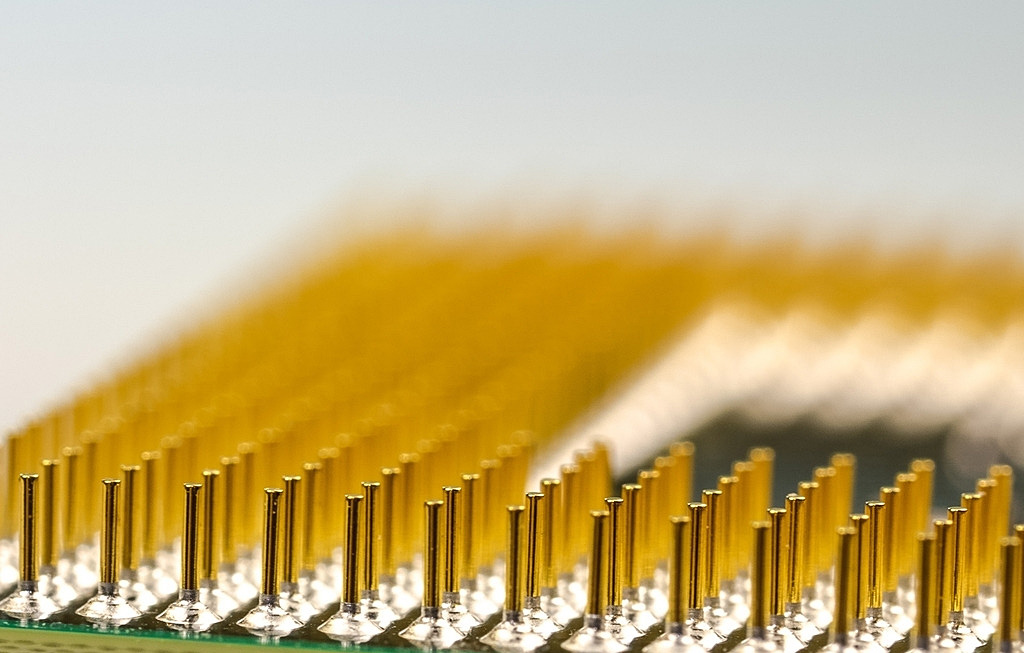

Next, the unique sensing capabilities of a non-tactile detection skills initiative increase reliability and security and can also be significantly improved for certain requirements in difficult environments.

For instance, in the welding profession; the central profession of industrial production and protective services is the welding profession. The current situation of the welding profession in China is as follows: manual welding is the major welding which is less active, less powerful, low quality, with a poor working condition.

The demand for welding professionals in industrial development and modern societies and is high cost performance, high power, high quality, and safety. In response to this expectation, several companies have introduced the use of a CCD Visual inspection machine in the field of active welding. For the time being, some companies have set up calibration systems for high speed sewing, based on structured lighting. The system was entirely developed independently by Sipotek company. They understudied and mastered proven practical skills in the United States and Europe.

It has been customized and designed based on the prevailing state of the domestic welding initiative, to enhance the development of existing equipment and welding machines.

Sipotek Technology has a variety of visual inspection machines that allow easy and quick detection of flaws in a product. They also have the single click detection machine that is easy to operate and is fast and efficient to perform testing. The machine is designed to shorten the inspection time and reduce the human error, while assembling or manufacturing a product. With its rapid detection technique, the machine software quickly matches the template and detects the defects or missing components. The company helps automate the manufacturing process and enables companies to stay competitive.

One can check the features of their inspection machines by visiting the website http://www.sipotek.net/ .

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Shenzhen Sipotek Technology Co., Ltd is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net