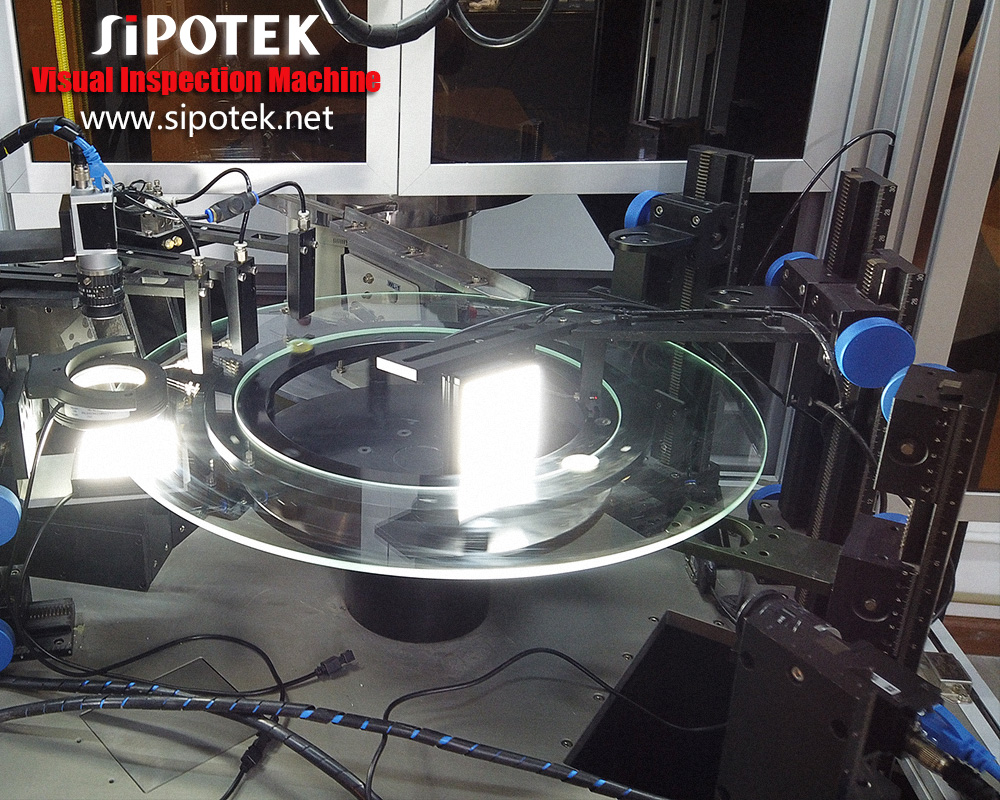

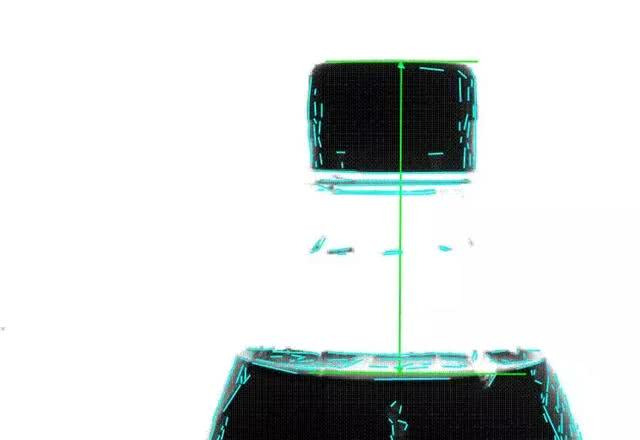

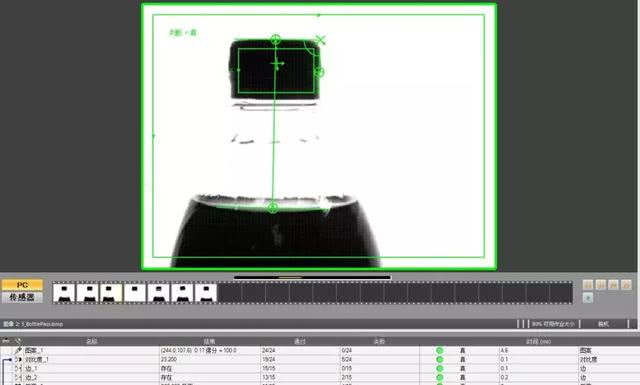

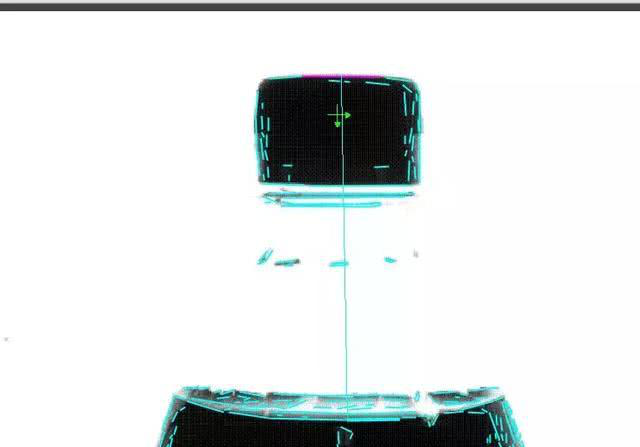

This article mainly introduces the application of machine vision technology in automatic inspection of plastic product surface defects such as liquid level, seal and cap of the bottle. The final result of the test is shown in the figure below.

In the molding process of plastic products, due to the influence of materials, molding process, mold, product design and equipment, various surface defects often occur. For example, the injection products may have insufficient filling, depression, sink marks, dark lines, and fusion. Traces, silver, spots, oil, burrs, bubbles, delamination, turbulence, spray marks, dull and uneven gloss, warpage, surface scratches and cracks.

There are two types of methods for plastic product surface defects inspection, conventional detection methods and automatic detection methods. Traditional detection methods include manual visual inspection and surface stroboscopic detection. The method is inefficient and error-prone, but most companies still use such methods. In recent years, the detection of defects in plastic products has adopted automatic inspection methods based on machine vision technology, and has been gradually promoted and applied in enterprises.

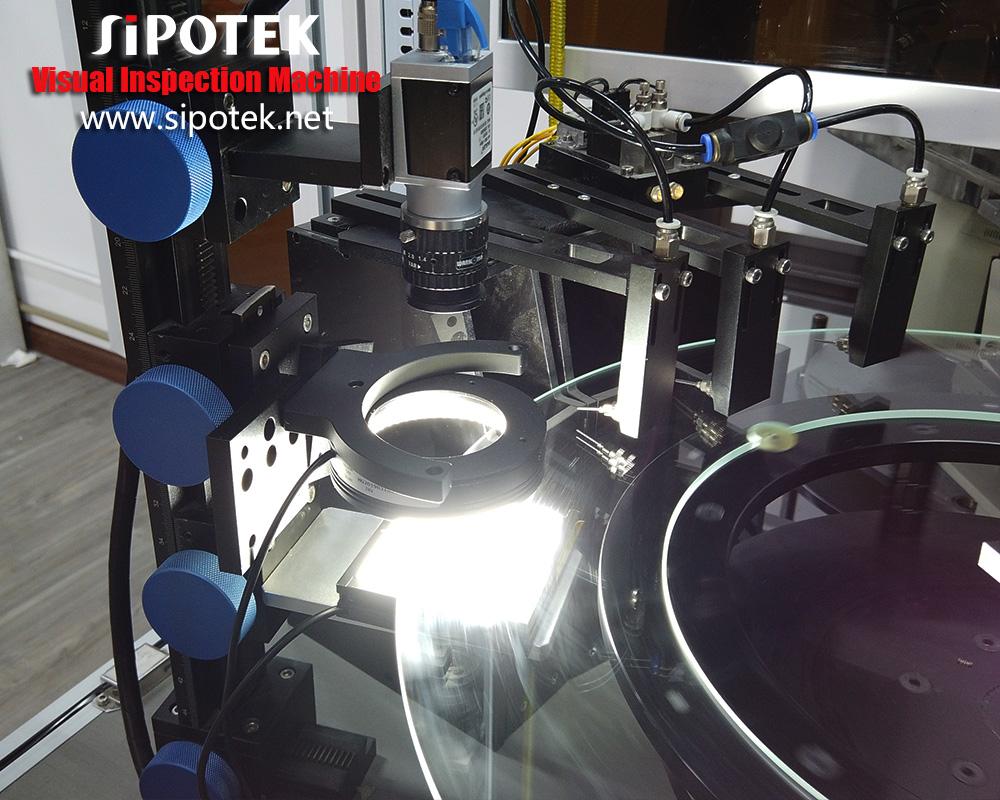

- Step 1: Capture images

There are two ways of collecting offline and online. Offline is to capture the images stored in the folder in advance, while online collection is to connect the camera to collect images in real time.

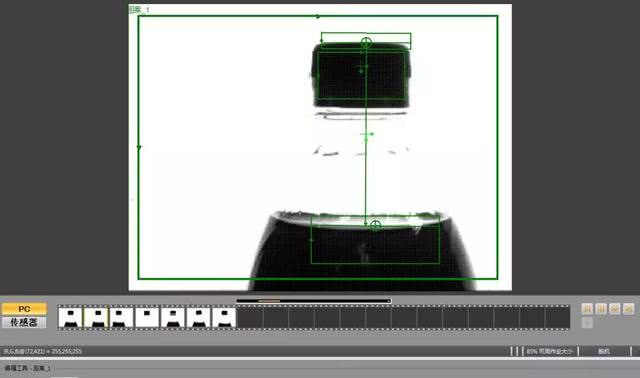

- Step 2: Pattern positioning

Add the positioning tool “pattern”, train the model that needs to be positioned, and train the bottle cap as the positioning model to perform pattern positioning.

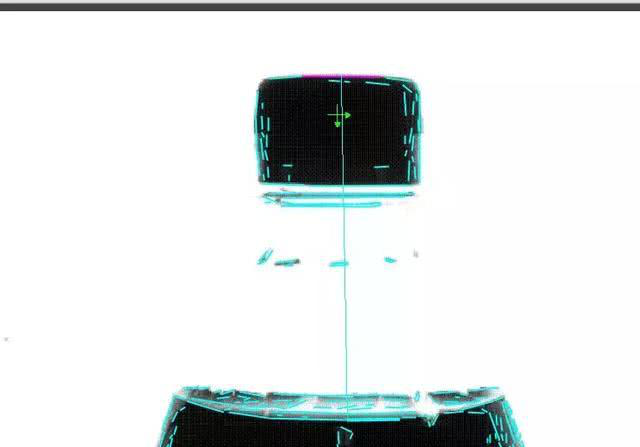

- Step 3: Contrast detection

Add the contrast tool and select the detection area. As shown in Figure 3, set the upper and lower limits. The contrast is OK in the interval, otherwise NG.

- Step 4: Level measurement

Add the distance measurement tool, select two edge features, set the upper and lower limits of the liquid level, and the liquid level height is OK in the interval, otherwise NG.

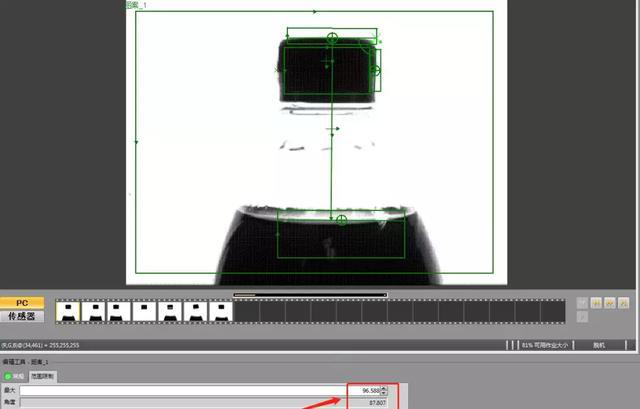

- Step 5: Angle measurement

Add an angle measurement tool and select two edge features. Set the upper and lower limits of the angle measurement. The angle is OK in the interval, otherwise NG.

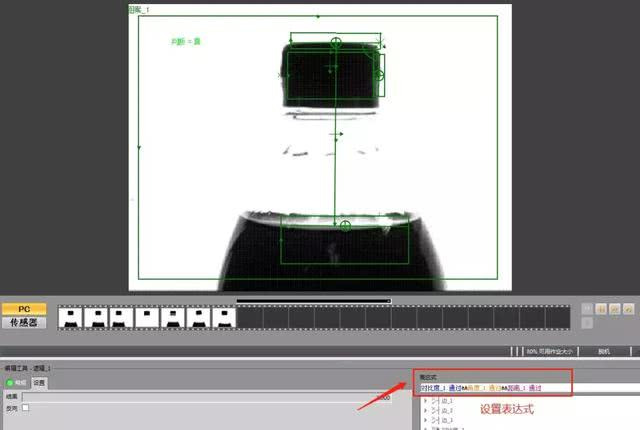

- Step 6: Logical judgment

Add the logic tool and set the expression; when the liquid level, seal and cap of the bottle are OK, the machine vision system judges that the bottle is qualified, otherwise it is unqualified.

- Step 7: Output the result

Machine vision primarily uses computers to simulate people or to reproduce certain intelligent behaviors associated with human vision. Information is extracted from the image of the objective object for processing and understood, and finally used for actual detection and control. The application of machine vision technology to intelligently and automatically detect the surface defects of plastic products can improve the detection efficiency and precision, and greatly improve the production efficiency and production automation.

To learn how a visual inspection machine can automate the production process, one can visit the website http://www.sipotek.net/ .

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/industries/

| vision system inspection |