As long as it is a commercial products, there must be a set of standard. If it is out of the standard, it will be defined as a non-conforming product. A lot of inspection is involved in the product packaging, including size measurement detection.

Today i will share with you the online inspection solution of the cap in packaging production.

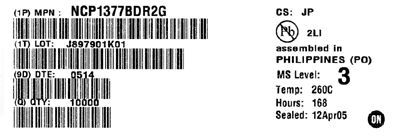

QR code, date of production or date of warranty will be often printed in the common platform, and some caps are also printed with bar codes. This style of printing has an obvious feature, that is the quantity volume which has high requirement for the printing information. Use machine vision to quickly and efficiently detect caps with printing problems.

The data of production will be printed on the bottle cap of general food packaging. Usually use ink-jet printer, other is printed by laser printer. The flexible of ink-jet printer is higher, but it will easy to cause poor printing, such as defects, blurring and incomplete printing. The application of laser printer is relatively infrequent, but it is easy to overlap and leak and other defects.

If use manual inspection, there is a lot of workload and the inspection speed can’t be improved. Optical image sorting machine adopts industry camera to convert the detect target into an image sign and perform calculations to realizes an automatic inspection and recognition function for the defective products, performs fast and accuracy sorting with an accuracy rate is up to 99% which is an effect that cannot be achieved by manual detection.

To response to these problems, Sipotek optical image sorting machine can put forward automated online inspection solution for the above problems. To sort and reject the problem of fond blurring, code deformation, character errors and dot characters can’ t be connected in the printing process.

Take a drink date as an example:

1.Bottom cap printing character detection

The printing character on the bottle cap curved surface, the concave and convex stripes are obvious, it is difficult to detect by visual inspection. Sipotek improves the characters by lighting so as the character base is highlight, the character is black and feel them is in a smooth plane, visual color characters will be clearer to inspection.

2. Outer packaging printing characters inspection

On the outer packaging, the bar code will be printed on the product itself and on the label so as the enterprise can build a product tracking system to meet the requirement of the enterprise can collect the product information in a real time. With its excellent reading abilities, Sipotek can accurately and quickly read the characters on various of packaging material.

With the increasing requirement of quality standard in food industry, not only the characters coding requires strict detection. But also the reading and verification of bar codes and QR codes are more important in many detection process.

Sipotek has focused on machine vision system solutions with 16 years research experience. Automated online inspection machine has significant advantages in bar code and QR code recognition.

For more about vision inspection machine,you can pay a visit to sipotek website at http://www.sipotek.net

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/vision-solutions/