During massive production, hundreds and thousands, even millions of products can be made at a same time. What machine vision inspection will help for these huge number of production? There are still many manufactures that adopting hundreds of inspectors do the inspection by human naked eyes, 8 hours a day, 5/6 days a week. Neglecting the cost and time of human inspection, what matters most is the efficiency of the inspection. 100% correction percentage is hard to make. People will have doubts that even a people cannot make sure for 100%, the machine designed by people can do. This is a normal question before people choose to try their first inspection machine.

In this case, we collect several questions and explain to you with answers.

- Q: How many workers can be replaced by the inspection machine?

A: The machine performance differs from the products to be inspected. For small items, it can replace 8-10 workers; For big items, it can replace around 3-5 workers. The key point lies in the reliability and stability of the machine. Generally, the inspection work by machine will be more stable, while the human inspection work will be affected by mistakes and fatigue.

- Q: What’s the inspection range?

A: Our machine can be applied in a variety of industries. We have experience in precision hardware, magnetic parts, plastic accessory, rubber parts, zippers, labels, character recognition, pharmacological stopper, etc.

- Q: What’s the correct percentage of the inspection sorting machine?

A: When sorting the qualified products, the accuracy percentage can reach 99.9%, but actually it’s reaching 100% certainty most of the time. The feeding performance depends on the stability of both product material and production. If a QC staff can inspect 97 pieces qualified items out of 100 pieces, the machine can generally inspect 95 pieces. The material stability and lighting will influence the inspection. What we can be sure is that the qualified items are all correct inspected as OK.

- Q: What is the delivery time?

A: The standard machine will be ready in 15 work days.

The delivery time varied from the destination of delivery.

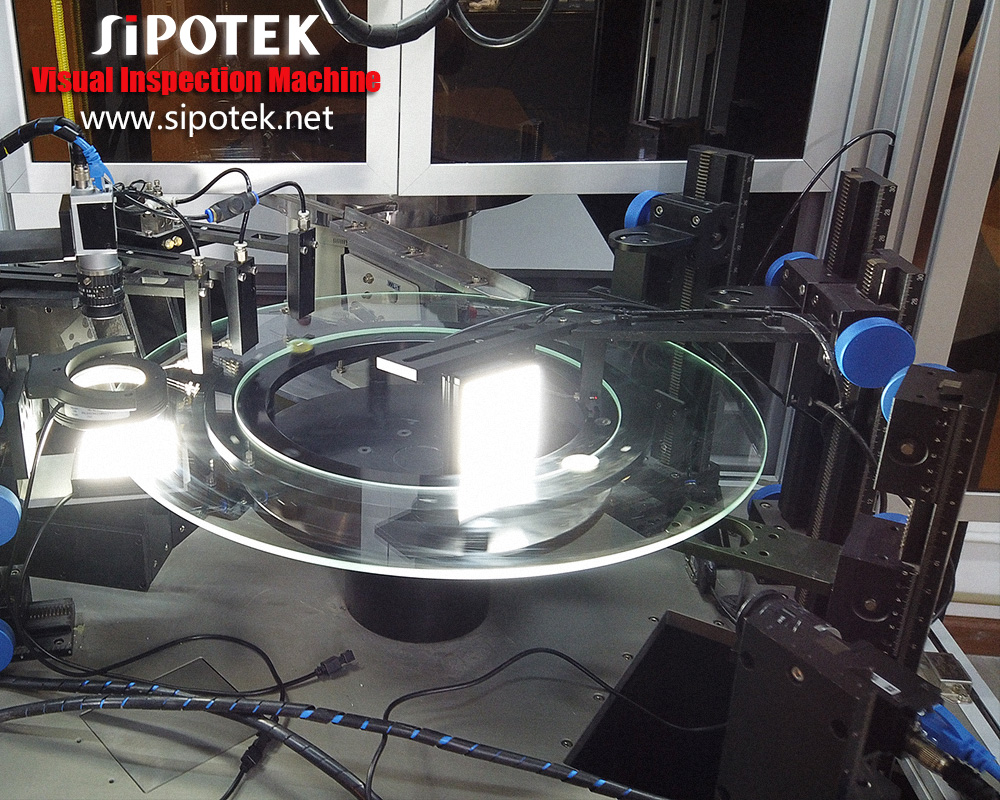

Machine vision inspection equipment is non-contact, high precision and automatic. Compared to general image processing system, machine vision emphasized the accuracy and speed, as well as the reliability in industrial on-site environment.

Machine vision inspection is suitable for measurement, detection and identification in the process of massive production. For example, part assembly integrity, assembly dimensional accuracy, part processing accuracy, position or angle measurement, part identification, features or word recognition, etc.

To learn more information about MVS or VOI inspection system and machine, please with Shenzhen Sipotek Technology Co., Ltd. http://www.sipotek.net/

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: [email protected]

Website: http://www.sipotek.net/