Vision inspection solution is a project designed from vision inspection manufacturers or designers for customers to get better understanding of they requirements of inspection contents, speed per minute, accuracy and inspection platform. It will provide a machine 3D structure or design picture for customers. Before we can test the samples and make a solution, customers will provide enough details in advance.

Inspection models

How many model products should be inspected in one machine? Basically according to our experience, a machine can inspect maximum 3 models with similar features. That means you can not use an apple inspection machine at the same time inspect the peanuts. But you can use it to inspection apple A, apple B or apple C.

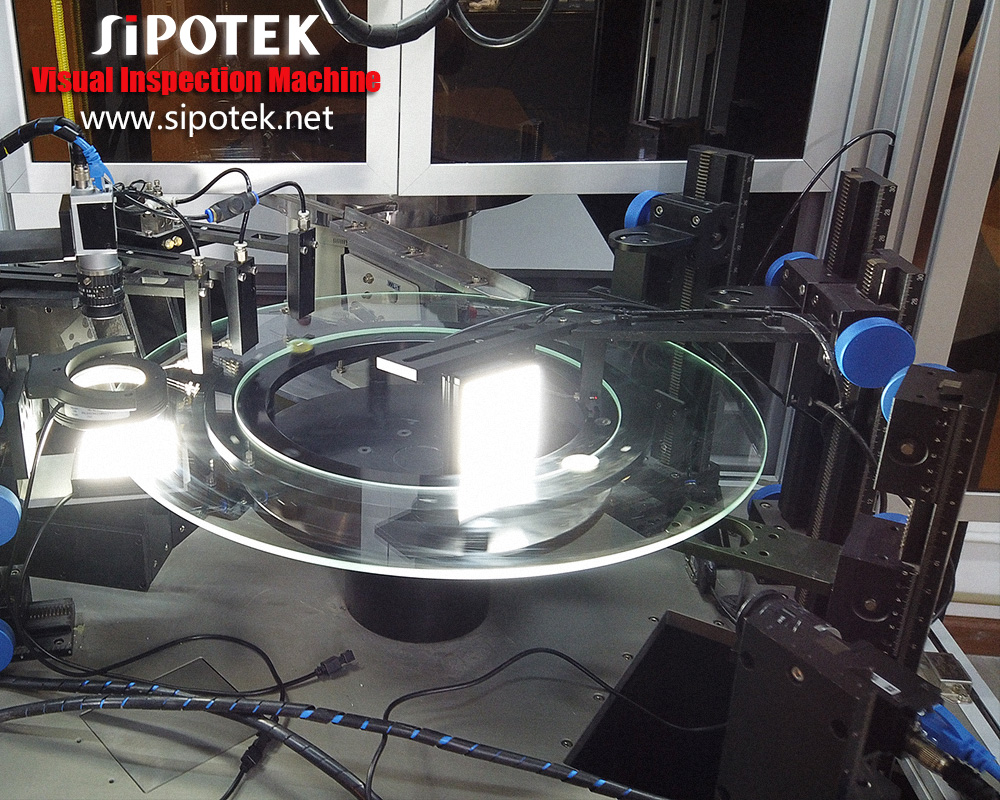

Sipotek Visual Inspection Machine

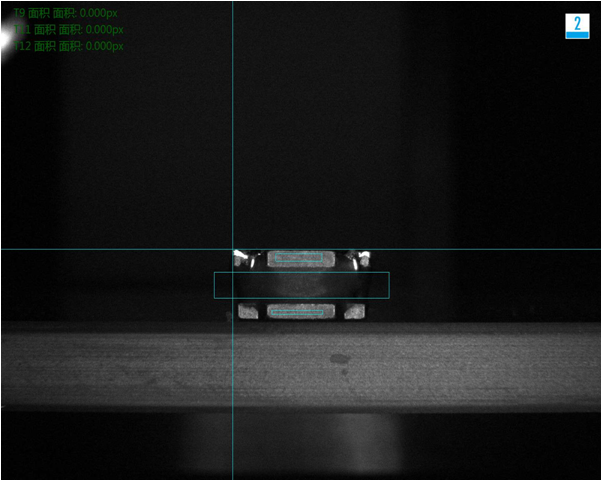

Inspection dimensions

Size / Dimension measurement is one the the regular vision inspection task for machine vision. Many items should have critical size control. The drawings will be provide to our engineers for evaluation. Remember it must have highlighted marks showing which sizes should be measured.

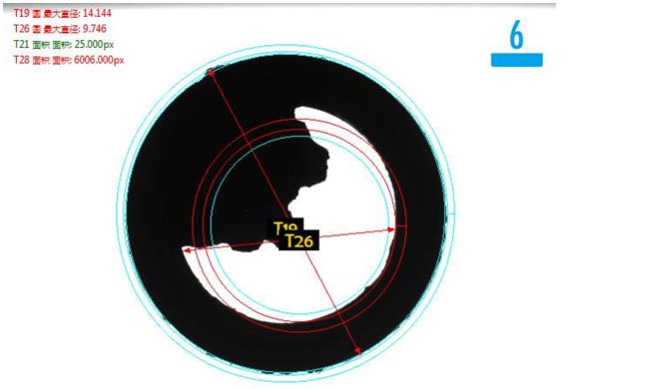

Not good samples

For defective inspection ,also called surface defects, appearance, or cosmetic defects, we usually ask customer to provide 6-10 pcs of each defects.

Defects No.1…Defects No.2… Defects No.3…..

All the defects must be described clear in what position they will appear, because the solution will be based on them.

Pictures of defective samples

Some customer will forget to separate the defective samples. It will delay the time for testing. If customer can provide the pictures of the defective samples, it will help us separate the massive samples faster. But the best way is that customer separate their samples on their own because they are the one who knows the defects degree. Sometimes the minimum size of defect is the limits for a vision inspection software to set the templates.

Good samples

We also need good samples to do the master templates. For dimensional inspection only, the customers only need to provide good samples. But for defective inspection, bad and good samples are both needed. They have to make comparison.

Product features

The products will be put onto an inspection stationary for inspection. The stationary will be either a glass or a transparent conveyor belt and will work continuously hours. So we have to consider the features when products be placed in the the environment. Will they be fragile, get dirty, or get scratched, oily, etc.

Contact us if you have any quiries.

Sipotek Visual Inspection Machine 7

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-186 1718 2707

Email: [email protected]

Website: http://www.sipotek.net/machines/