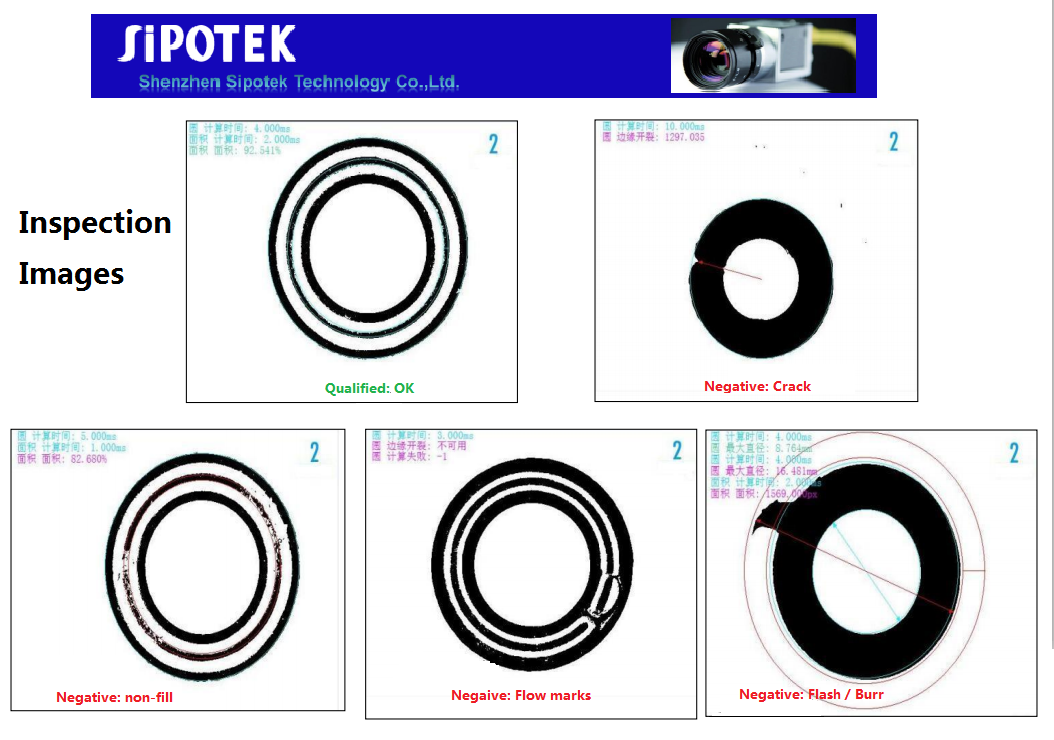

Possible o-ring failure are happened during manufacturing process. Analysis of the seal application is crucial to the understanding of possible o ring failure. Understand the following common failure will help us better make a solution to visually inspect the defects by machine vision systems.

- Gland design. Incorrect groove or gland design, improper o-ring sizing, hardware damage or misalignment.

- Compression set. The seal exhibits a flat-sided cross section, the flat sides corresponding to the mating seal surface. It’s due to excessive compression, excessive temperature. In completely cured elastomer.

- Over compression. Failure to account for thermal or chemical volume changes, or excessive compression.

- Explosive decompression. The seal shows blisters, pits or pocks on its surface.

- Installation damage. The seal or parts of the seal may exhibit small cuts, nicks or gashes. Sharp edges on glands or components will cause this problem.

- The o-ring or parts of the o-ring will show a flat surface parallel to the direction or motion. Loose particles and scrapes may be found on the seal surface. It was because the excessive temperature and process environment contains abrasive particles.

- Extrusion, pressure or oversized gland clearance gap. The seal develops ragged edges (generally on the low-pressure side) which appear tattered.

- Spiral twisting failure. The seal exhibits cuts or marks which spiral around its circumference.It was because of difficult or tight installation, slow reciprocating speed. Inadequate lubrication.

- Chemical degradation. The seal may exhibit many signs of degradation including blisters, cracks, voids or discoloration. In some cases, the degradation is observable only by measurement of physical properties.

- Plasma degradation. The seal often exhibits discoloration, as well as powdered residue on the surface and possible erosion of elastomer in the exposed areas.

There are other reasons caused the failure of o-ring quality. Whatever reasons are they, we can verify the defects by doing a lighting test. Usually front light is used to check over compression, abrasion, extrusion, spiral twisting failure and chemical discoloration, etc. While the back light is used to check o-ring dimensions such as diameter and heights.

About us

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of machines vision systems for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-186-1718-2707

Email: [email protected]

Website: http://www.sipotek.net/machines/