Many manufacturers use automated machine vision instead of human inspectors because it is better suited to repetitive inspection tasks. It is faster, more objective, and works continuously. Machine vision systems can inspect hundreds or even thousands of parts per minute, and provide more consistent and reliable inspection results than human inspectors.

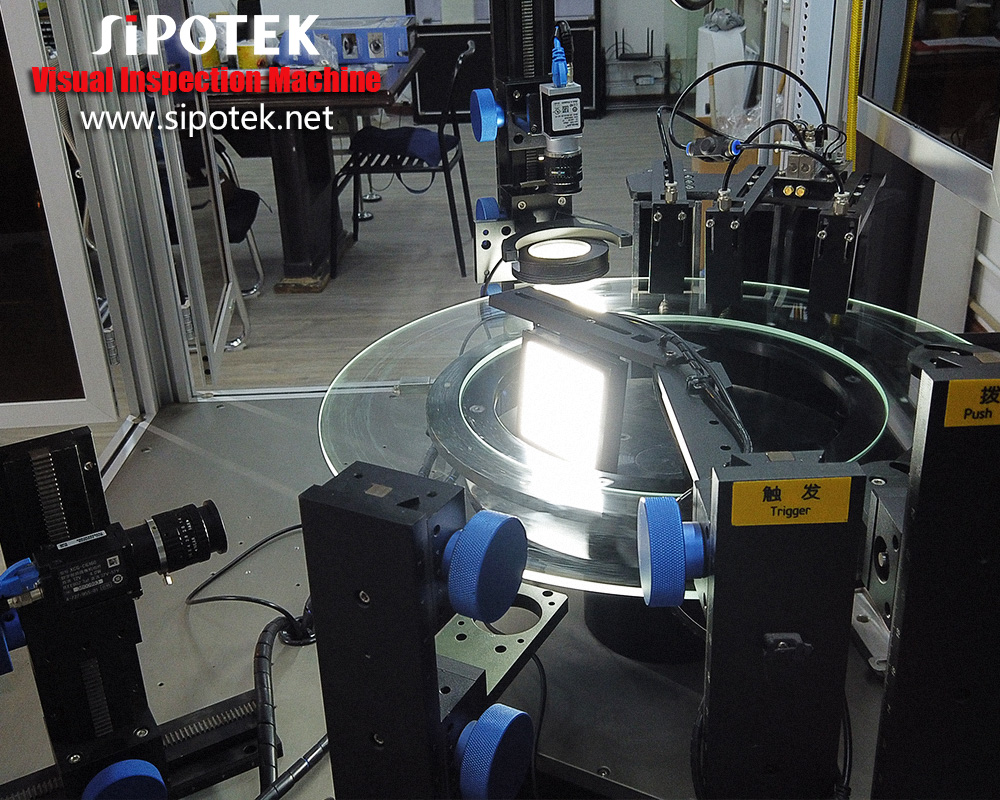

Machine vision is the technology that utilized multiple cameras setting in specific position, ready to be triggered to capture images of the objects, and then transfer the image data through imaging processing system to the inspection system. The inspection works is triggered when receiving the signal of image processing system and begin to deal with the images data and give analysis and detection automatically, usually in an industrial or production environment. A typical application might be on an assembly line. Before we sell our product, the inspection procedure is a must, so the inspection work is necessary if we can put a machine vision inspection tool before we pack and deliver our goods. The cameras is programmed to check the position of something, its color, size or shape, or whether the object is there or not. It can look at and decipher a standard or 2D matrix barcode or even read printed characters.

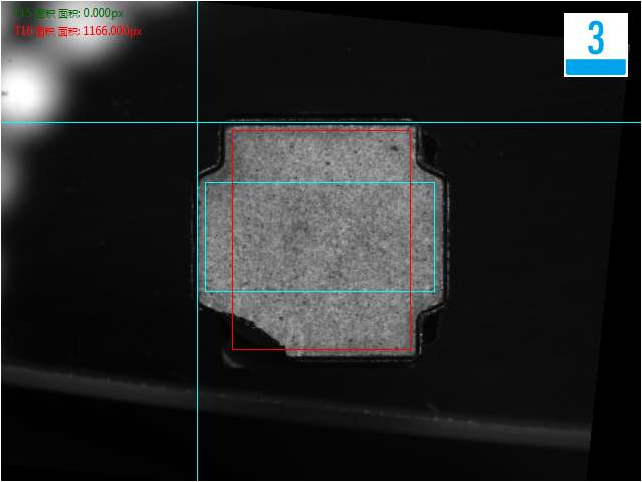

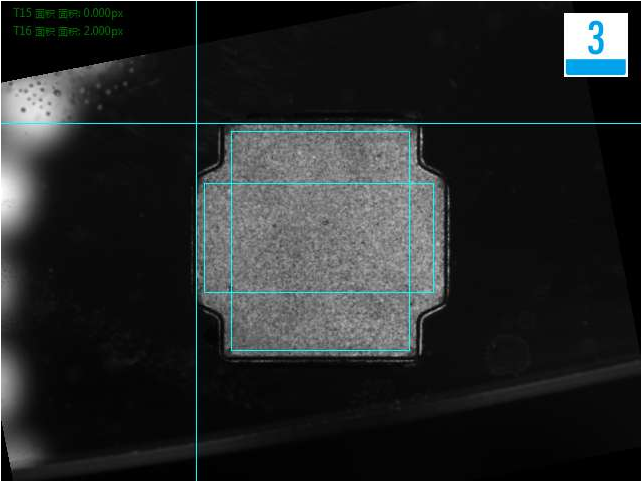

Now the product is inspected through the machine vision system. After it has been inspected, a signal is usually generated to determine what to do with it. The part might be recognized as qualified with OK or unqualified with NG. The part then will be rejected into a container or special tray or an offshoot conveyor, or passed on through more assembly operations, tracking its inspection results through the system. In any case, machine vision systems can provide a lot more information about an object than simple absence/presence type sensors.

Typically the function for machine vision include.

- Quality assurance

- Robot/machine guidance

- Test and calibration

- Real-time process control

- Data collection

- Machine monitoring

- Sorting

- Counting

- Radar recording

By reducing defects, increasing yield, facilitating compliance with regulations and tracking parts with machine vision, manufacturers can save more money and increase company profitability. So much benefits for a company to choose a machine vision insepction machine to replace human hand inspection. It will become an increasing need for industrial applications.

Established in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. Sipotek is a professional machine vision inspection system manufacturer from china.The Sipotek Technology staff supports customers 360 degrees automatd optical inspection(AOI), from listening to their requests to the development of ambitious machines for quality control.

For Media Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: +86-18617182707

Email: [email protected]

Website: http://www.sipotek.net/