Sipotek focus on machine vision inspection for 16 years on industrial applications. Here is a case for stainless steel gear wheel visual defects inspection.

- Inspection requirement

Samples are reveived before we can do the lighting test for an esimtation vision inspection solution.

Product name: steel gears

Size: Diameter 0.6mm -30mm

Inspection positions: Bottom face, missing teeth; Top face, missing teeth;

Inspection speed: 200-400 pieces according to samples

- Equipment setting

Model number: T300

Complete machine size: 900 Length*800 Width*1850 Height (mm)

Complete machine net weight: 300 KG

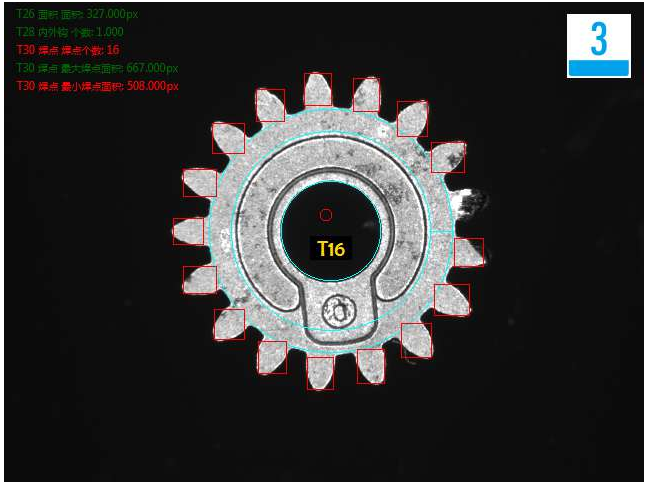

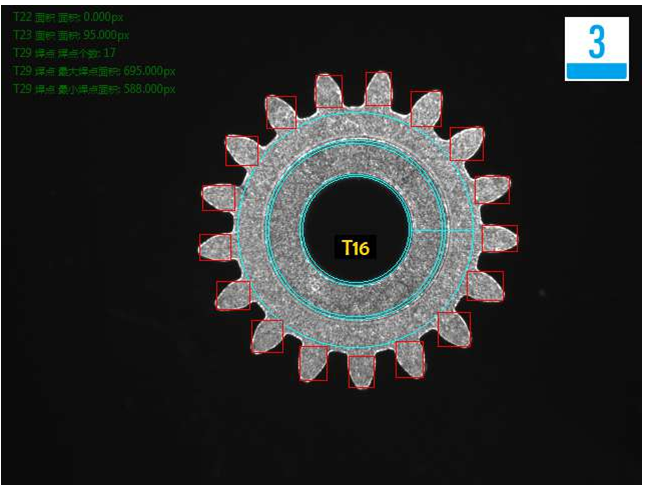

Inspection Images from this vision inspection machines

Configurations:

- 1 x Sipotek vision inspection software

- 1 x Industrial computer with keyboard and mouse

- 1 x Screen display 19 inch

- 2 x Industrial cameras ( one for top face, one for bottom face)

- 2 x Industrial FA lens

- 1 x Professional glass rotary plate

- 1 x vibration feeder ( including bowl holder, linear vibrator and controller)

Packing list:

1 x Machine host

1 x Vibration feeder

About us

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-186 1718 2707

Email: [email protected]

Website: http://www.sipotek.net/machines/